The Critical Role of PESDs in Electrical Safety

Understanding when and how to use Permanent Electrical Safety Devices (PESDs) for voltage presence and absence testing is crucial. These devices significantly enhance safety protocols and ensure compliance with industry standards like NFPA 70E. This blog explores the vital roles of different PESDs, the associated risks of operating without them, and the dual benefits of incorporating both types into your safety measures.

Understanding Voltage Presence and Absence Testing

Voltage testing in industrial settings involves two critical aspects: verifying the presence of voltage to identify live circuits and confirming the absence of voltage to ensure systems are safe to work on. Each type of testing serves a unique purpose in maintaining electrical safety:

- Voltage Presence Verification: This is crucial for confirming that power systems are operational before performing any maintenance that requires power.

- Voltage Absence Testing: Essential for verifying that systems are completely de-energized before beginning any repair or maintenance work to avoid electric shock or other accidents.

When to Use Voltage Indicator PESDs

PESDs equipped with voltage indicators provide crucial safety and operational advantages across various workplace scenarios:

- Safety Enhancement: Offers a visual confirmation of energy presence, enhancing safety during Lockout/Tagout (LOTO) by preventing accidental energization.

- Compliance Aid: Helps in adhering to LOTO standards, thus minimizing compliance risks and potential penalties.

- Operational Efficiency: Facilitates safer and more efficient inspections by providing clear visual status of voltages, eliminating the need to expose workers to live circuits.

- Speed and Safety: Enhances the troubleshooting process, allowing for quick and safe identification of operational voltages, which speeds up diagnostics and reduces error rates.

- Regulatory Adherence: Supports compliance with crucial safety standards like NFPA 70E, ensuring facilities meet regulatory requirements and avoid fines.

- Educational Tool: Acts as an effective training aid by visually demonstrating energy presence, which can be pivotal for both new and existing staff in understanding and implementing safe practices.

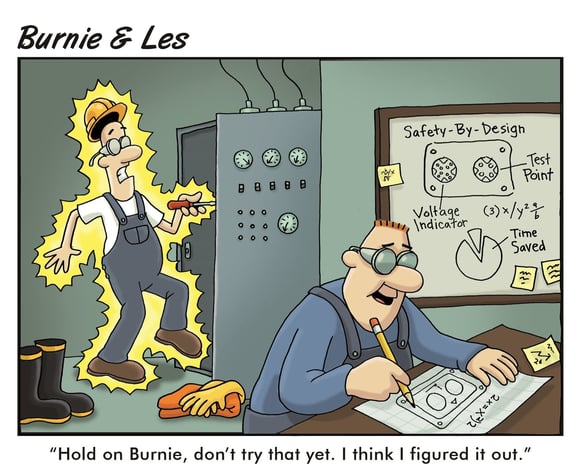

Without voltage indicator PESDs, workers assuming equipment to be de-energized face severe risks:

Without voltage indicator PESDs, workers assuming equipment to be de-energized face severe risks:

- Electric Shock and Arc Flash: Potential for severe injuries or fatalities due to unexpected energization.

- Equipment Damage: Misoperations based on incorrect energy status assumptions could lead to costly damages.

- Unexpected Machine Energization: Working on machinery presumed de-energized but still powered can lead to severe injuries or fatalities, equipment damage, and compliance violations.

- Compliance Violations: Failure to properly verify energy status can lead to breaches of safety regulations, resulting in fines and increased regulatory scrutiny.

Incorporating PESDs with voltage indicators is essential not only for enhancing safety but also for ensuring compliance and improving operational efficiency. Consider the critical role these devices play in a comprehensive electrical safety strategy.

When to Use High-Impedance Protected Test Points PESDs

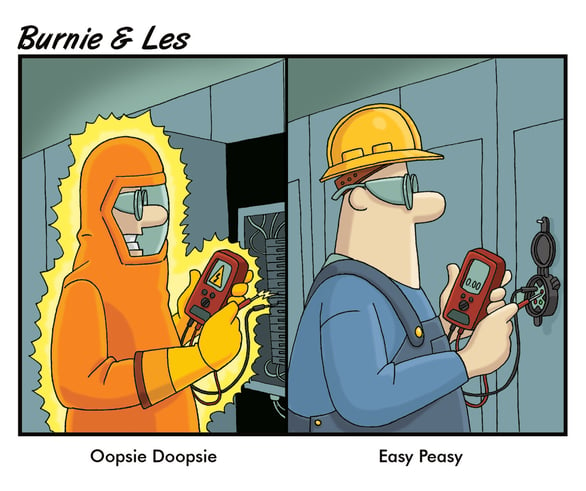

Workers benefit greatly from the ability to conduct absence of voltage tests externally through high impedance-protected test points in various critical situations:

- Arc Flash and Shock Prevention: Allows for verification of de-energized conditions without opening enclosures, greatly reducing the risk of arc flash and electric shock.

- Regulatory Adherence: Helps ensure compliance with OSHA and NFPA 70E standards for LOTO, facilitating safe and standard-compliant procedures without direct exposure to hazards.

- Time Savings: Streamlines maintenance and troubleshooting by enabling quick, safe verification of electrical isolation directly from outside the panel, reducing downtime.

- Safety with Convenience: Decreases the need for extensive personal protective equipment, simplifying the process and enhancing speed and comfort for technicians.

- Elimination of Phantom Voltages: High impedance-protected test points provide accurate testing, preventing false readings and enhancing safety and reliability.

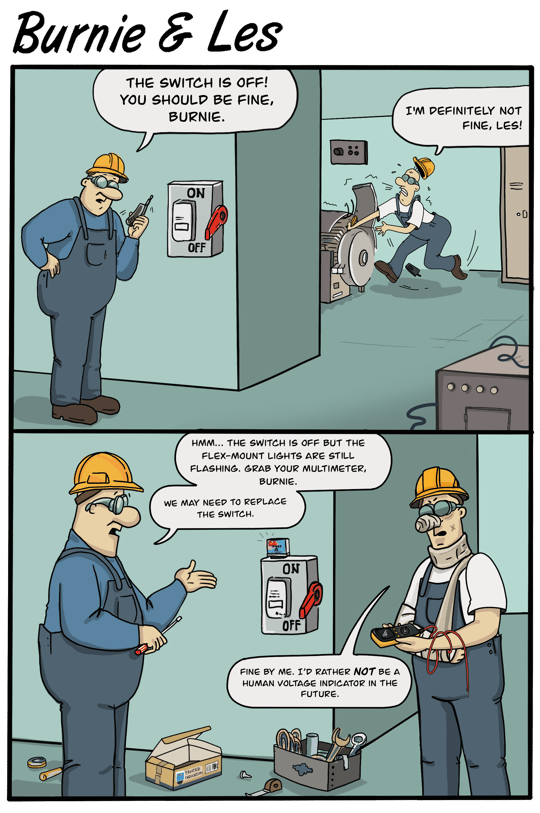

Without PESD test points, workers and operations face increased risks and productivity challenges:

Without PESD test points, workers and operations face increased risks and productivity challenges:

- Higher Exposure to Hazards: The necessity to open panels and contact components increases the risk of arc flash and electrocution.

- Potential Non-Compliance: Missing PESD test points can lead to violations of safety standards like NFPA 70E, attracting fines and legal complications.

- Increased Operational Downtime: More time-consuming safety procedures, including full PPE and manual checks, lead to increased downtime and reduced productivity.

- Greater Human Error Risk: Manual testing without PESDs is susceptible to errors, possibly overlooking live circuits thought to be de-energized.

Incorporating PESD test points not only fortifies safety protocols but also streamlines operations, making them indispensable in modern electrical safety practices.

The Role of PESDs

PESDs like voltage indicators and test points simplify testing processes. They provide a safer, more efficient way to perform these tests by eliminating the need to expose workers to direct electrical hazards.

- Voltage Indicators: Allow for the quick detection of live circuits without direct contact, showing clear, visible indications through LEDs.

- High Impedance Protected Test Points: Enable qualified personnel to safely check for the absence of voltage from outside the panel, minimizing exposure to electrical hazards.

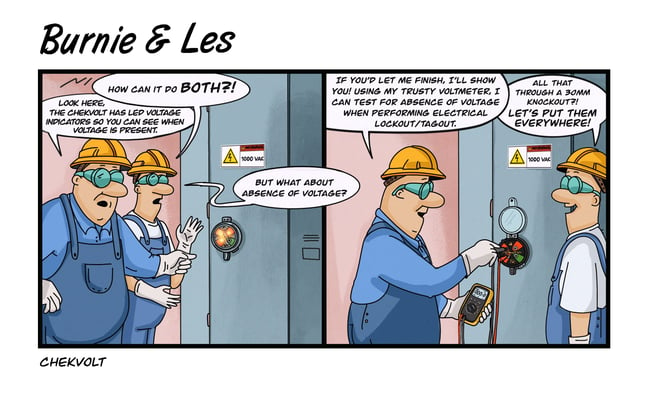

For facilities looking to integrate comprehensive safety solutions, products like the Voltage Test Station and ChekVolt offer combined functionalities.

- Voltage Test Station: Houses both indicators and test points within a single unit, providing a complete solution for verifying electrical safety.

- ChekVolt: Merges the functionality of standalone voltage indicators and test points into a single, more efficient device. This tool not only fits the same footprint as a 30mm knockout but also includes flashing LEDs to indicate voltage presence, significantly enhancing safety and compliance ease.

The Best of Both Worlds

While individual use of voltage indicators or test points markedly improves safety and compliance, integrating both types of PESDs into electrical safety protocols provides comprehensive protection against electrical hazards. The ChekVolt is a prime example of such integration.

This device combines the immediate visual assurance of voltage indicators with the definitive safety check of absence of voltage test points. It offers a robust solution tailored to meet the rigorous demands of modern industrial environments where efficiency and safety are paramount.

Don't compromise—request a ChekVolt sample today and see how integrated voltage testing can transform your approach to electrical safety, making your environment safer and more efficient.