Navigating the Hazards of Arc Flash

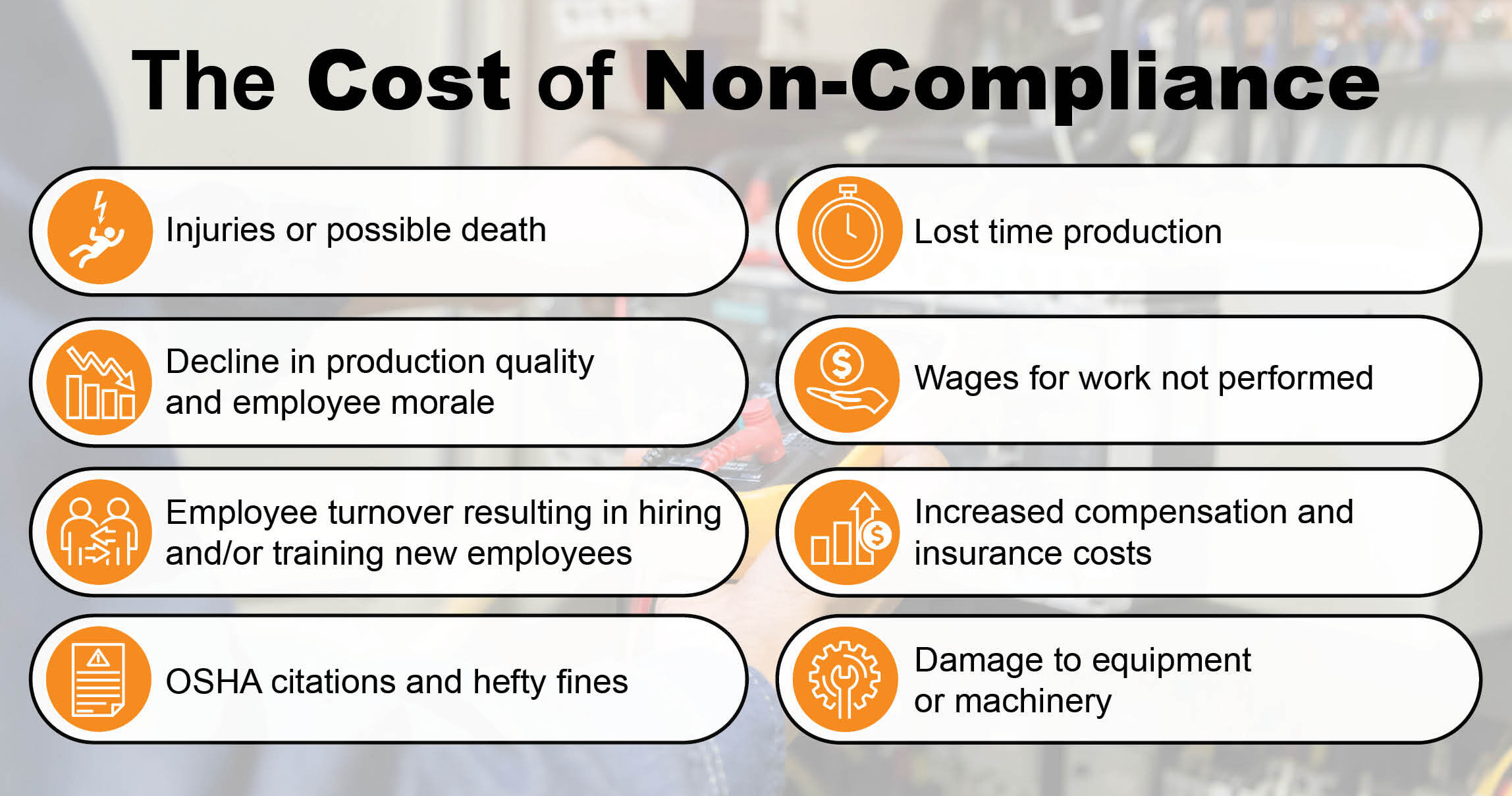

Arc flash incidents pose significant risks in the workplace, leading to severe injuries and even fatalities. As businesses strive to create safer environments, understanding and applying the hierarchy of control can drastically reduce these risks.

This blog delves into the arc flash phenomenon, strategies for mitigation, and the crucial role of Permanent Electrical Safety Devices (PESDs), with a focus on how they fit into the safety hierarchy.

Understanding Arc Flash Risks

An arc flash is an explosive release of energy caused by an electrical fault, characterized by high temperatures, intense light, and pressure waves. These incidents can cause burns, blindness, hearing loss, and, in severe cases, death.

The NFPA reports that electrical injuries account for hundreds of workplace fatalities and thousands of injuries each year, underscoring the need for rigorous safety protocols.

Mitigating Arc Flash Risks Through the Hierarchy of Control

The hierarchy of control is a systematic approach used to minimize or eliminate exposure to hazards. It is a staple in occupational health and safety management, providing a framework for controlling risks:

- Elimination: Removing the hazard entirely from the workplace. This is the most effective control measure and, in the context of arc flash, could involve de-energizing electrical equipment before work is performed.

- Substitution: Replacing the hazard with a less dangerous option. This might involve using lower voltage equipment where possible to reduce arc flash potential.

- Engineering Controls: Isolating people from the hazard using physical means. This is where PESDs become particularly relevant.

- Awareness: Enhancing hazard recognition and safety awareness among all employees. Awareness strategies include labeling, signage, and visual aids that alert workers to potential electrical hazards

- Administrative Controls: Changing how people work by implementing procedures or training to reduce exposure to the hazard. This includes safety training, work permits, and arc flash risk assessments.

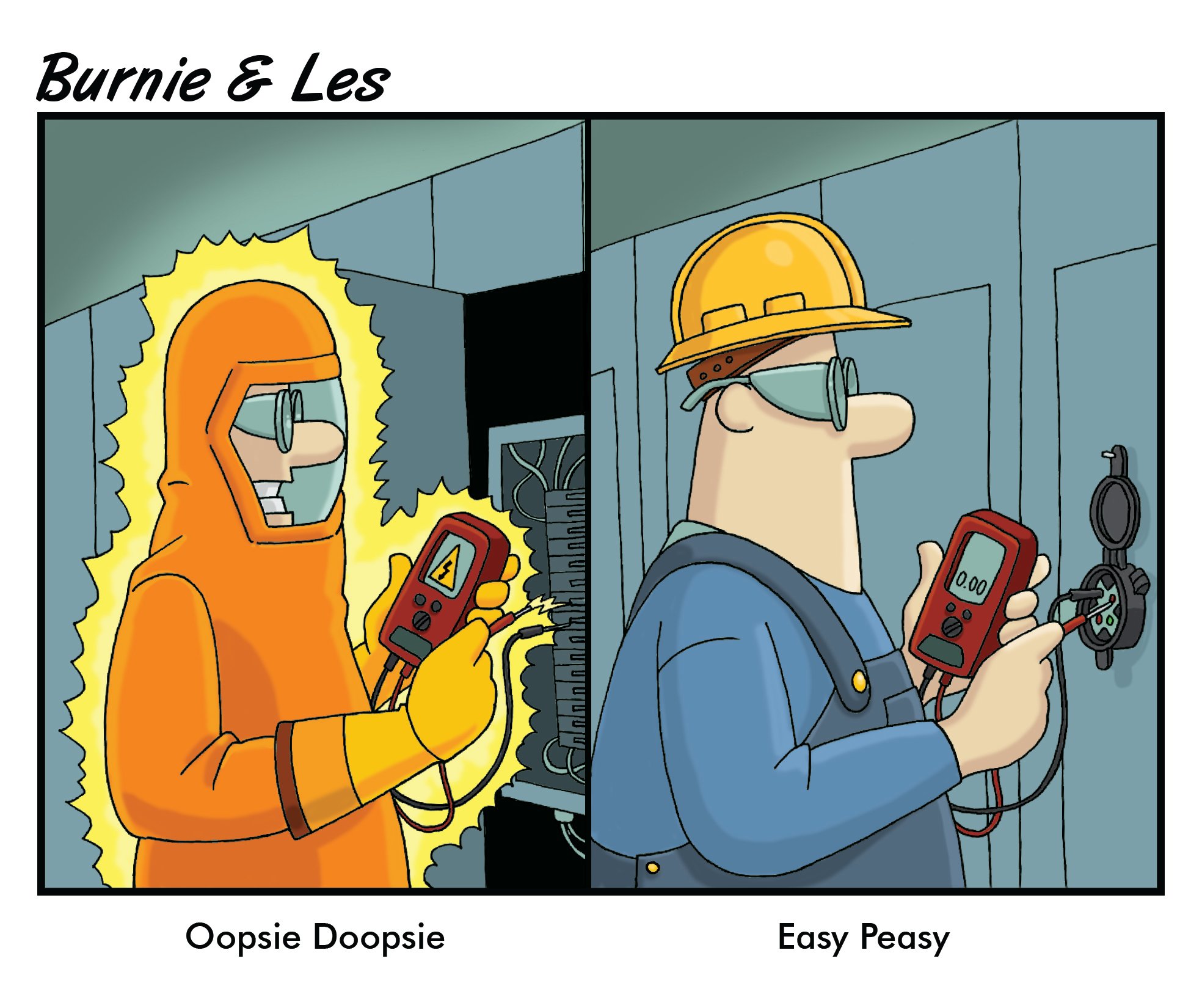

- Personal Protective Equipment (PPE): Using protective gear to reduce exposure to hazards when other controls cannot eliminate risks. PPE is the last line of defense and includes arc-rated clothing, gloves, and face shields.

.jpg?width=400&height=416&name=Risk%20Control%20Hierarchy%20(1).jpg)

The Role of PESDs in the Hierarchy of Control

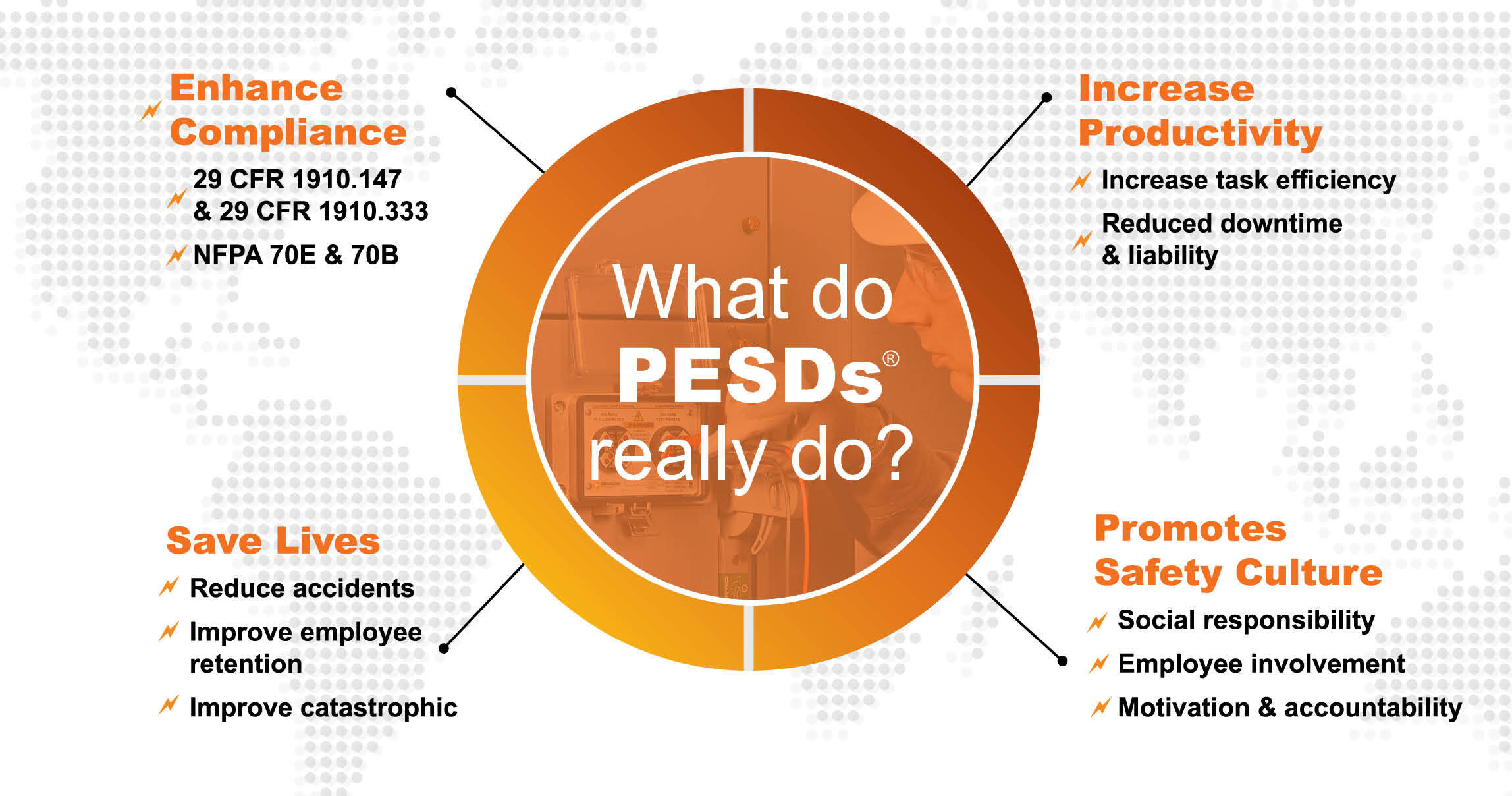

PESDs fall under the category of Engineering Controls, Awareness, & Administrative Controls within the hierarchy. They are designed to minimize direct interaction with electrical hazards, thus significantly reducing the risk of arc flash incidents. PESDs are engineered solutions that allow for the verification of an electrically safe work condition without direct exposure to electrical hazards.

Devices such as voltage presence indicators and absence of voltage test points play a crucial role in preventing arc flash incidents by ensuring that workers can safely determine the presence or absence of electrical energy. This minimizes the need for direct interaction with potentially dangerous electrical components, aligning with the principle of minimizing risk through Engineering Controls.

The Awareness stage of the Risk Control Hierarchy bridges the gap between passive Engineering Controls and active Administrative Controls. By ensuring that all personnel are aware of the hazards and the location and purpose of safety devices like PESDs, organizations can foster a culture of safety and vigilance.

Effective awareness measures ensure that the workforce is not only informed about the tools available to them, such as PESDs, but also understands their role in maintaining a safe working environment.

Administrative Controls set the framework for how engineering controls like PESDs are used in practice, detailing the procedures for their use and integrating them into daily safety protocols. Here’s how PESDs contribute to arc flash risk mitigation:

- Enhancing Safety: PESDs provide a means to verify the absence of voltage without exposing workers to the open panel, thereby reducing the risk of an arc flash event.

- Compliance: Using PESDs helps organizations comply with NFPA 70E requirements for establishing an electrically safe work condition, thereby integrating compliance into the fabric of safety procedures.

- Efficiency: PESDs streamline the process of verifying an electrically safe work condition, making safety procedures more efficient and less time-consuming.

Explore the Safety Benefits of ChekVolt

In the landscape of electrical safety, innovation and adherence to best practices are paramount. ChekVolt represents a leap forward in PESD technology, offering an efficient and reliable solution for verifying absence of voltage. This permanently installed device is instrumental in enhancing workplace safety and compliance with electrical safety standards.

We encourage safety professionals, electricians, and facility managers to explore the benefits of incorporating ChekVolt into their electrical safety protocols. Request a ChekVolt sample today and take a significant step towards mitigating arc flash risks in your workplace. By integrating advanced PESDs like ChekVolt, organizations can elevate their safety procedures, protect their employees, and foster a culture of safety excellence.

Understanding and applying the hierarchy of control, particularly engineering controls like PESDs, is crucial in the fight against arc flash risks. By prioritizing safety and adopting innovative solutions, we can create safer work environments and significantly reduce the incidence of electrical injuries and fatalities.

Join us for our upcoming webinar "Revolutionizing Safety: From PPE to Permanent Solutions." Uncover how the hierarchy of controls is reshaping industrial safety, emphasizing the hierarchy of controls and the shift from relying on PPE to integrating PESDs for enhanced electrical safety.

This session will guide you through enhancing your electrical safety protocols and solidifying your electrical safety compliance. Learn from real-world applications and case studies where PESDs have significantly reduced risks. Register now to elevate your safety standards and operational compliance.