The concept of safety by design has been a part of Grace since the very beginning. Our founder, Phil Allen, was incepted with the idea of the GracePort while working on a friction welder retrofit project at John Deere. The machine I/O was located in the front and the electrical panel had a 400 Amp main feed inconveniently located at the rear of the machine. Aware of the safety hazard this panel access presented, Phil invented a way to bring the connections he needed to the outside of the panel so that he could safely connect without exposing himself to hazardous energy.

The concept of safety by design has been a part of Grace since the very beginning. Our founder, Phil Allen, was incepted with the idea of the GracePort while working on a friction welder retrofit project at John Deere. The machine I/O was located in the front and the electrical panel had a 400 Amp main feed inconveniently located at the rear of the machine. Aware of the safety hazard this panel access presented, Phil invented a way to bring the connections he needed to the outside of the panel so that he could safely connect without exposing himself to hazardous energy.

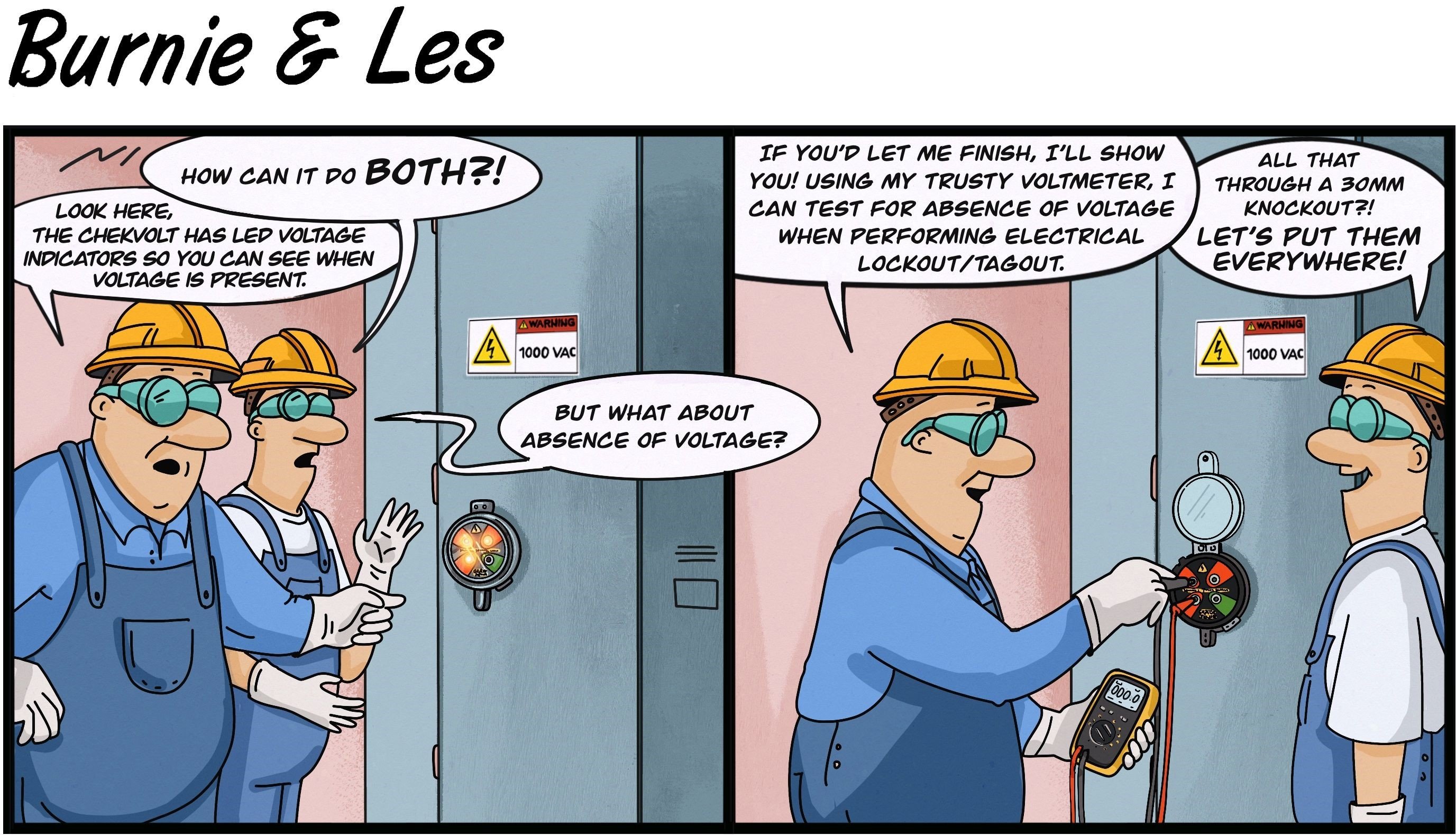

To this day, our engineering experts look at electrical safety and maintenance situations like these and devise solutions for safer practices. Grace's Permanent Electrical Safety Devices (PESDs) bring voltage presence LED indication and absence of voltage test points to the outside of an enclosure. PESDs incorporate the concept of safety by design by working within the established NFPA 70E 120.5 procedure for "Establishing and Verifying an Electrically Safe Working Condition".

- NFPA 70E 120.5(4) – PESDs with voltage indication LEDs illuminate when hazardous voltage is present until stored electrical energy is released, warning of hazardous voltage that may harm maintenance personnel believing equipment to be in a de-energized state.

- NFPA 70E 120.5(7) – PESDs with high impedance protected test points allow a qualified electrician to safely test phase-to-phase and phase-to-ground for absence of voltage using an adequately rated portable test instrument (i.e. voltmeter). Per 120.5 (7): “Before and after each test, determine that the test instrument is operating satisfactorily through verification on any known voltage source.”

One of the most cited violations each year is the OSHA standard outlining the minimum performance requirements for the control of hazardous energy during the servicing and maintenance of machines and equipment. In 2022, Lockout/Tagout (LOTO) was the sixth most cited OSHA violation receiving a total of 2,175 violations this year; 505 more than in 2021. By installing PESDs wherever LOTO procedures are performed, companies can facilitate additional safety measures into their written LOTO training program to ensure reduced risk, increased productivity, and enhanced compliance.

ChekVolt users report LOTO procedure time reductions of 35-40 minutes. ChekVolt pays for itself after 6-8 LOTO procedures from time savings alone! View Product Bulletin.

The latest PESD to emerge with safety by design is the ChekVolt. This compact electrical safety device allows qualified personnel to test for absence of voltage while simultaneously providing voltage presence LED indication; all without opening enclosure doors. With the enclosure closed, qualified electricians using their trusted voltmeters can insulate the meter's probes with .080” tips into any two test point jacks and take a voltage reading. With the addition of a ChekVolt within any electrical safety program, by following the proper safety procedures outlined in NFPA 70E, the user’s risk of arc flash or shock hazard is significantly reduced.

Grace's Business Development Team, Chris Schneck and Nick Augustine, sat down with Engineering Team Lead, Eric Norton, to discuss how the ChekVolt was engineered and produced with safety by design. Check it out!