Adhering to OSHA's electrical safety standards is not just a regulatory requirement but a cornerstone of workplace safety. The complexity of electrical work, combined with the high stakes of safety management, necessitates a detailed, step-by-step approach to ensure compliance and safeguard the well-being of employees.

This guide offers a pathway to not just meet but also enhance OSHA electrical safety standards, culminating in a safer, smarter, and more productive Electrical Safety Program (ESP).

Step 1: Understanding OSHA Regulations - OSHA 29 CFR 1910 Subpart S and OSHA 29 CFR 1926 Subpart K

Begin by getting acquainted with the OSHA standards that form the bedrock of electrical safety practices within your organization. OSHA 29 CFR 1910 Subpart S and 29 CFR 1926 Subpart K directly relate to establishing foundational knowledge of electrical safety standards within the workplace.

Subpart S outlines the design, installation, and protection standards for electrical systems in the general industry, while Subpart K addresses electrical safety standards in construction.

Familiarity with these regulations ensures that employers can develop safety protocols that meet federal requirements, providing a safe working environment for employees.

- Attend OSHA training sessions and webinars regularly.

- Consult with safety experts to remain abreast of the latest electrical safety standards.

- Implement a compliance audit system to identify and rectify non-compliance areas.

Step 2: Comprehensive Risk Assessment - NFPA 70E Article 110.1(H)(3)

Identifying potential electrical hazards is a critical step in safeguarding your workplace. NFPA 70E Article 110.1(H)(3) mandates performing risk assessments to identify and evaluate electrical hazards. This step is critical for planning actions to mitigate identified risks.

The NFPA 70E article reference underscores the necessity of a structured approach to risk assessment, aligning with the best practices of engaging employees and utilizing a recognized framework to systematically address potential hazards.

- Employ the NFPA 70E risk assessment framework to methodically identify hazards.

- Involve employees in the risk assessment process for a broader insight into potential hazards.

Step 3: Implementing the Hierarchy of Controls - NFPA 70E Article 110.1(G)

Effectively manage risks by applying the hierarchy of controls and prioritizing safer methods over PPE. NFPA 70E Article 110.1(G) details the application of the hierarchy of controls, emphasizing prioritizing methods like elimination and substitution over personal protective equipment.

The NFPA 70E article reference for this step is crucial as it guides employers in effectively managing risks by first attempting to remove the hazard or replace it with a less hazardous alternative before relying on protective gear, ensuring a safer workplace.

- Regularly review electrical systems for opportunities to apply elimination and substitution.

- Ensure regular inspections and maintenance of engineering controls.

Step 4: Training and Documentation - OSHA 29 CFR 1910.332 and NFPA 70E Article 110.2

Comprehensive training and meticulous documentation are pivotal for electrical safety. OSHA 29 CFR 1910.332 and NFPA 70E Article 110.2 both emphasize the importance of training and qualifications for personnel dealing with electrical hazards.

These references highlight the need for comprehensive training tailored to the unique electrical safety challenges faced by workers in their specific roles. Additionally, maintaining detailed documentation ensures compliance with these standards and provides a record of safety efforts and electrical system details.

- Develop role-specific training programs tailored to the unique challenges of your facility.

- Maintain an accessible digital repository of all electrical safety documents.

Step 5: Regular Maintenance and Inspections - NFPA 70E Article 205.3

Prevent potential issues from escalating into hazards with routine maintenance and inspections. NFPA 70E Article 205.3 states that electrical equipment must be maintained to minimize the risk of failure and subsequent exposure to electrical hazards. This directly relates to scheduling regular maintenance and inspections, ensuring that electrical systems and equipment are kept in safe working order.

The reference reinforces the importance of adhering to manufacturers' instructions or industry standards for maintenance, aligning with best practices for early identification of potential issues.

- Conduct regular audits and utilize diagnostic tools to detect wear and tear.

- Align maintenance schedules with manufacturer recommendations and best practices.

Step 6: Emergency Preparedness - OSHA 29 CFR 1910.38

Prepare for electrical emergencies with specific procedures and regular drills. OSHA 29 CFR 1910.38 mandates having an emergency action plan, which should include procedures for electrical emergencies.

This step's relation to the reference is vital, as it ensures that employers develop and implement comprehensive emergency procedures tailored to electrical safety. This preparation is crucial for an effective and swift response to incidents like electrical fires, shocks, and arc flash incidents, thereby enhancing workplace safety.

- Tailor emergency response plans to cover various electrical safety scenarios.

- Ensure regular drills are conducted so employees understand their roles in an emergency.

By following these steps and adhering to the references provided, employers can create a safer workplace that is compliant with OSHA and NFPA 70E standards, thereby mitigating risks and enhancing overall safety.

Beyond Compliance: Grace's Expert Network Consulting Service

Achieving compliance is a significant milestone, but true safety excellence requires going beyond the minimum requirements. Our Expert Network Consulting Service for ESPs offers a pathway to not just achieve but excel in electrical safety standards. Our service encompasses:

- Tailored consulting to develop and implement a compliant, fully defendable ESP.

- Integration with overall occupational health and safety management systems, addressing unique facility needs.

- Enhancing worker productivity and safety at scale, while reducing regulatory risks and managing liability.

We invite you to take advantage of a free assessment to gauge your compliance with OSHA standards and explore how our Expert Network can elevate your electrical safety protocols. This service ensures that the knowledge gained from training moves to field application, supported by documented policies, practices, and procedures. It's not just about meeting standards; it's about setting new ones.

Adhering to OSHA's electrical safety standards is a complex but crucial process. By following these steps and leveraging expert services like Grace's Expert Network, you can ensure compliance, enhance safety, and foster a culture of continuous improvement. Remember, safety is not a destination but a journey, requiring ongoing effort, expertise, and commitment.

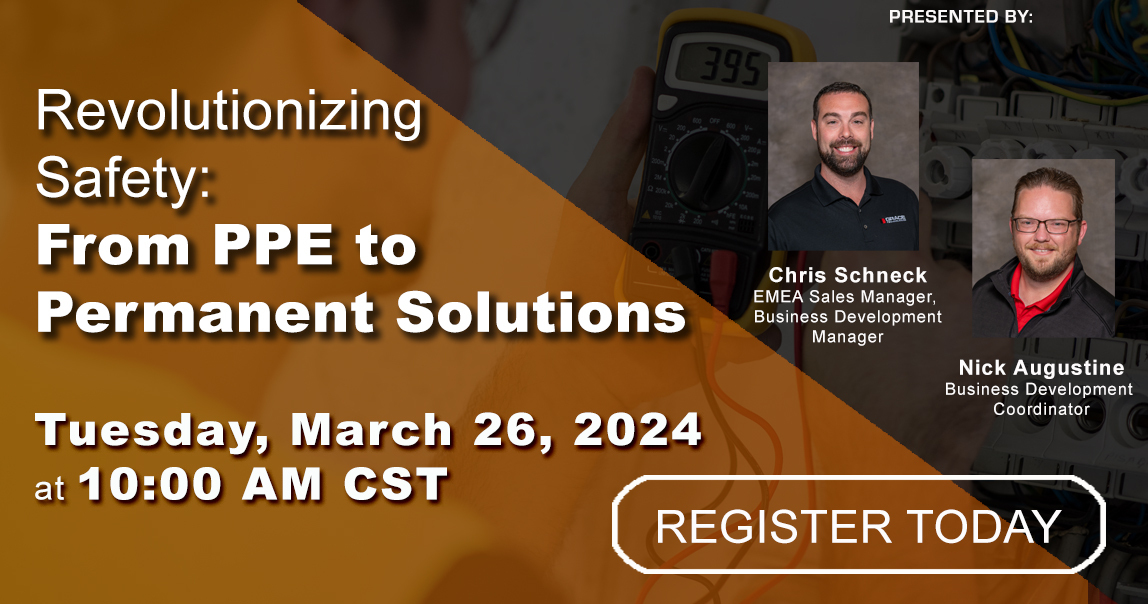

Join us for our upcoming webinar "Revolutionizing Safety: From PPE to Permanent Solutions." Uncover how the hierarchy of controls is reshaping industrial safety, emphasizing the hierarchy of controls and the shift from relying on Personal Protective Equipment (PPE) to integrating Permanent Electrical Safety Devices (PESDs) for enhanced electrical safety.

This session will guide you through enhancing your electrical safety protocols and solidifying your electrical safety compliance. Learn from real-world applications and case studies where PESDs have significantly reduced risks. Register now to elevate your safety standards and operational compliance.