The Role of ChekVolt PESDs in Renewable Energy and EV Infrastructure

As renewable energy solutions and electric vehicles (EVs) become more prominent, organizations must keep pace by ensuring safety in high voltage direct current (DC) systems. With increasing installations of solar power systems and EV charging stations, there is a growing need for effective Lockout/Tagout (LOTO) procedures and reliable absence of voltage testing to protect workers and equipment.

The ChekVolt family of Permanent Electrical Safety Devices (PESDs) offers innovative solutions tailored to meet these demands, enhancing both safety and productivity across various industries.

The Expanding Landscape of Solar and EV Charging Stations

The renewable energy sector is witnessing rapid growth, with solar energy and electric vehicle infrastructure leading the charge. According to the International Energy Agency (IEA), global solar PV capacity is expected to nearly triple over the next decade.

EV adoption is surging, with the IEA projecting that the number of electric cars on the road will reach 145 million by 2030.

Streamlining LOTO Procedures with ChekVolt

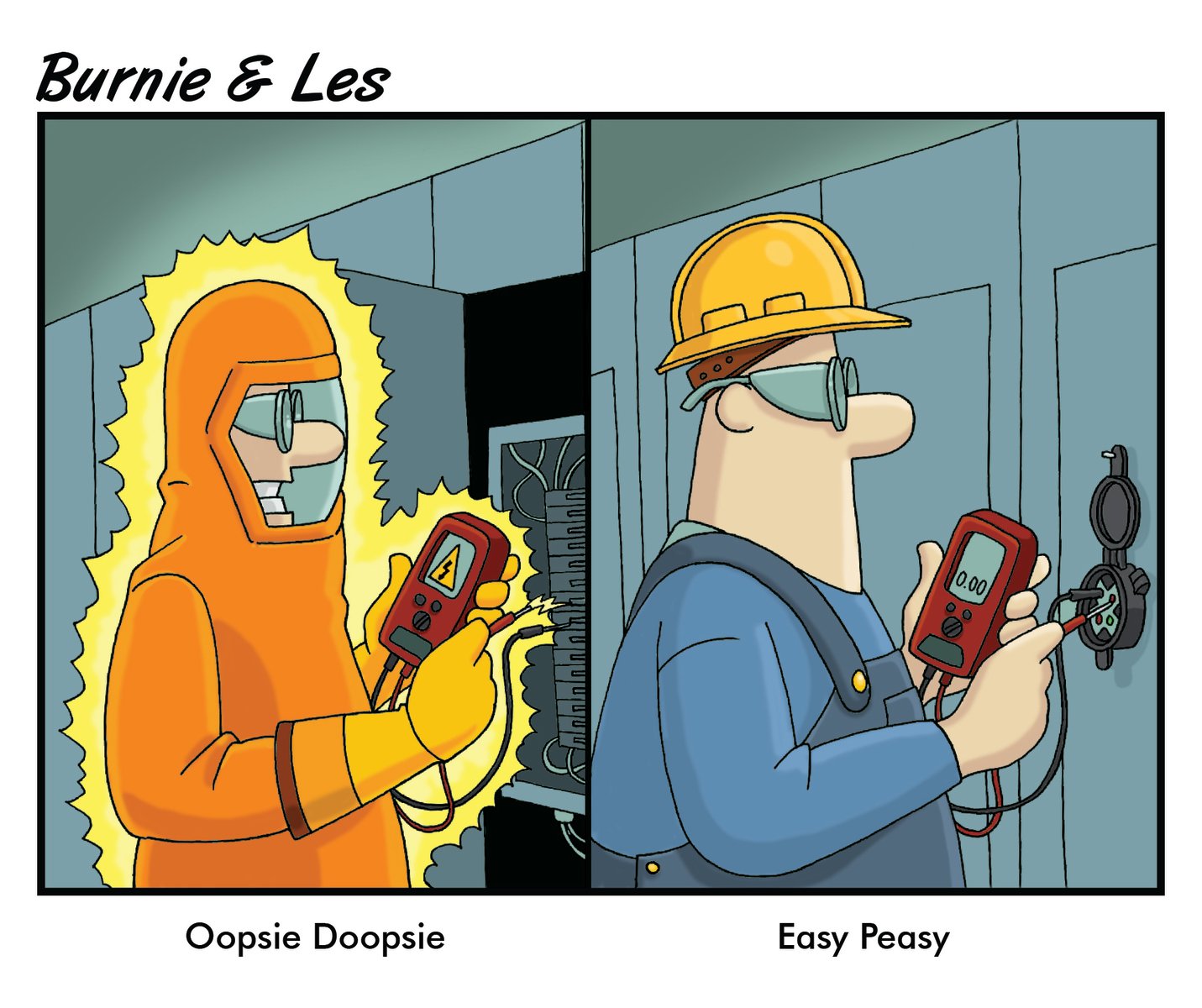

LOTO procedures are essential for safely isolating electrical equipment during maintenance. However, these procedures can be time-consuming and prone to errors. The ChekVolt PESD simplifies LOTO by enabling safe and compliant absence of voltage testing using multimeters for live-dead-live tests.

This significantly reduces the time needed for each procedure, with users reporting time savings of 35-45 minutes per procedure. This efficiency not only boosts productivity but also enhances safety by providing clear, immediate voltage presence indicators.

The Versatility of ChekVolt Variants

Recognizing the diverse needs of various industries, Grace offers multiple ChekVolt variants:

- ChekVolt AC3: Ideal for environments with single-phase power applications up to 1000VAC.

- ChekVolt DC2: Perfect for solar panels and EV charging stations with two-wire DC systems up to 1000VDC.

- ChekVolt DC3: Designed for three-wire DC systems up to 1000VDC, ensuring compatibility with specific installation standards.

Whether you are in the solar, EV, or other industry, we have a ChekVolt variant tailored to your specific needs. Each variant is engineered to provide maximum safety and productivity, ensuring compliance with OSHA and NFPA 70E standards.

Enhancing Safety and Productivity in Solar Applications

In solar power systems, maintaining safety during maintenance is critical. The ChekVolt DC2 and DC3 variants are particularly beneficial in these settings, providing clear visual indications of voltage presence or absence, thus reducing the risk of electrical hazards.

This capability allows maintenance personnel to perform LOTO procedures without opening enclosures, significantly enhancing safety and efficiency.

Ensuring Safe Maintenance in EV Charging Stations

EV charging stations, especially those utilizing high voltage DC for fast charging, pose unique safety challenges. The ChekVolt DC2 and DC3 variants are designed to handle the higher voltages associated with these stations.

By incorporating ChekVolt into their maintenance routines, EV charging stations can ensure safe and reliable operations, promoting the broader adoption of electric vehicles and contributing to a more sustainable future.

Grab a ChekVolt for Your Application

ChekVolt's innovative design and versatility make it an essential tool for enhancing electrical safety across various applications. By streamlining LOTO procedures and providing reliable absence of voltage testing, ChekVolt helps industries maintain compliance with safety standards while boosting productivity.

For more information on how ChekVolt can enhance your safety and productivity request a sample today. We'll follow up with you ASAP!