The Critical Role of Live-Dead-Live Testing

The adherence to rigorous testing protocols is not just a matter of compliance but a fundamental aspect of ensuring the well-being of electricians and personnel. Among these protocols, the live-dead-live test stands as a cornerstone, underpinning the safety measures that guard against electrical accidents.

Dive into the essence of live-dead-live testing, its pivotal role in electrical safety, the consequences of its omission, and how modern technology, such as the GracePESDs ChekVolt, is revolutionizing safety procedures to enhance protection and productivity within the parameters of NFPA 70E 120.6.

Why Live-Dead-Live Testing is Important

Lockout/Tagout (LOTO) procedures are crucial for maintaining workplace safety by preventing accidents stemming from the release of hazardous energy. However, compliance issues persist, as evidenced by the significant number of OSHA violations.

These violations endanger worker safety and impose heavy financial burdens on companies, with significant penalties for LOTO Standard 29 CFR 1910.147 violations. These statistics underscore the urgency of adhering to LOTO and electrical safety protocols:

- LOTO Citations: OSHA has issued over 10,000 LOTO citations since 2014, with penalties reaching up to $13,260 per violation.

- Electrical Fatalities and Injuries: A slight year-over-year increase in electrical fatalities and a 17% increase in electrical injuries highlights the ongoing risks electricians and related personnel face.

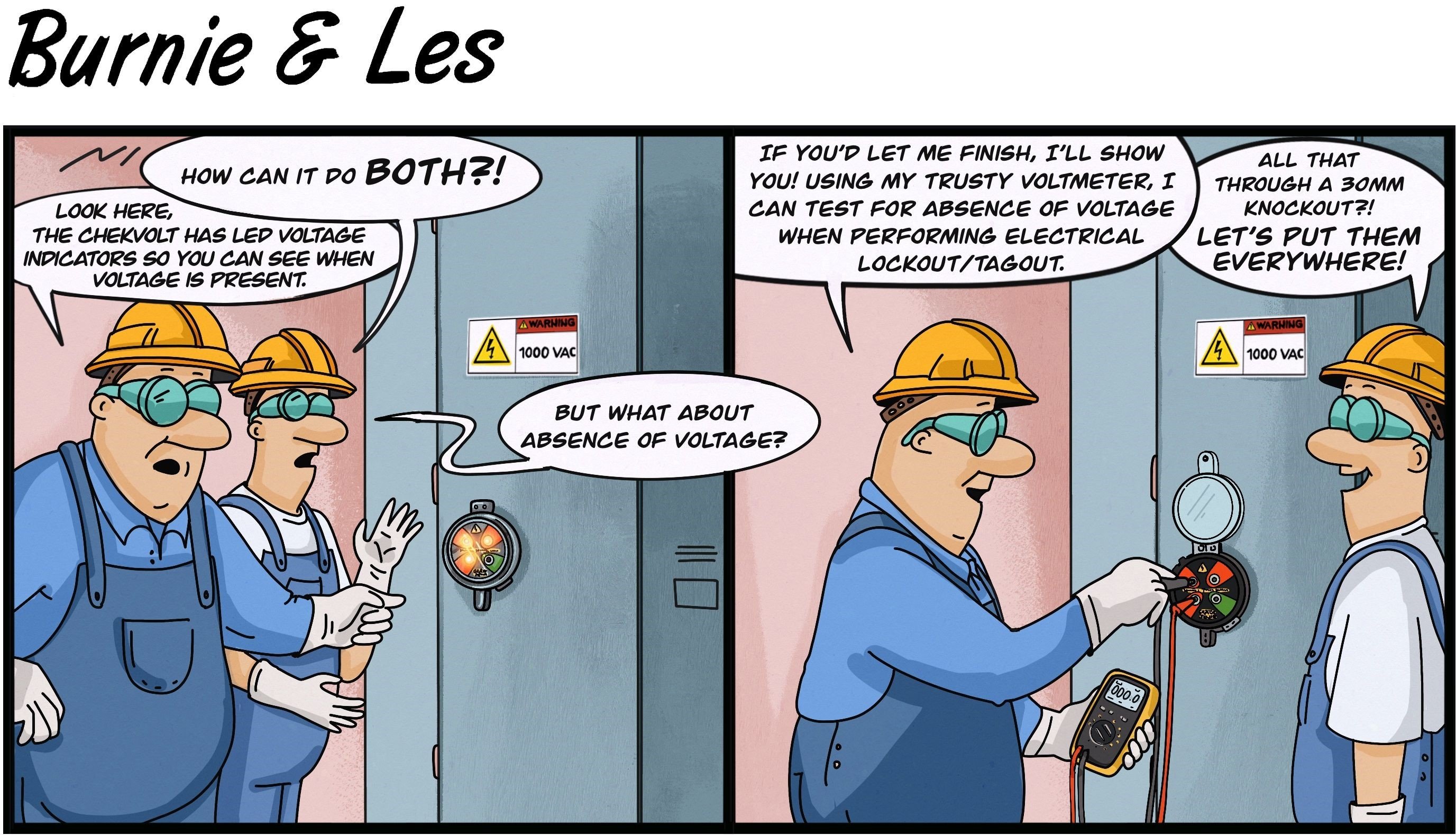

ChekVolt: Enhance Safety & Productivity for Live-Dead-Live Testing

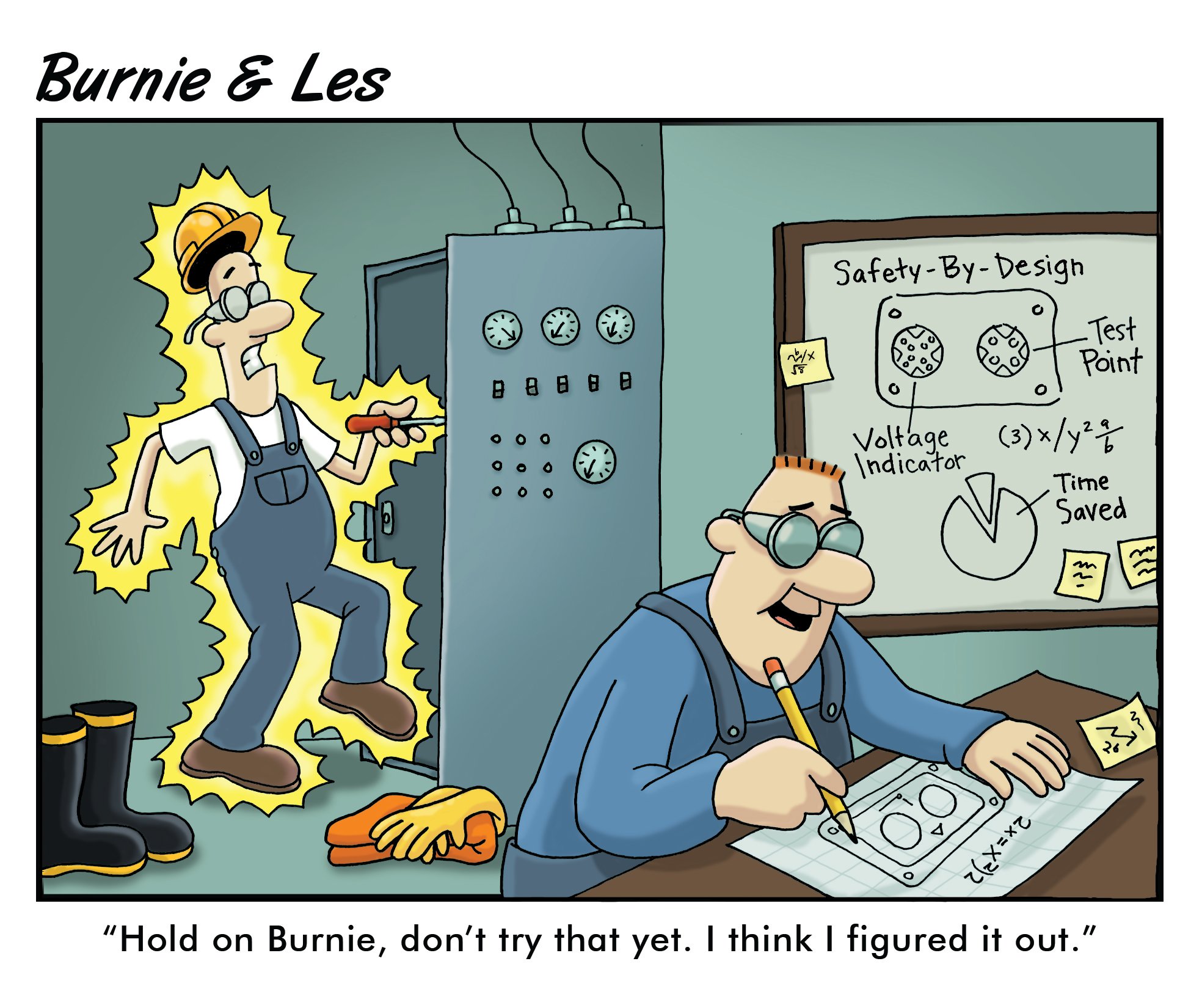

Live-dead-live testing is an indispensable practice in the electrical industry, crucial for preventing accidents and ensuring the safety of workers. The introduction of technologies like the ChekVolt further enhances these safety protocols, merging compliance with efficiency to foster a safer, more productive workplace.

For employers and electricians alike, investing in safety is not just a regulatory obligation but a moral imperative, with the potential to save lives and prevent injuries. The ChekVolt represents a leap forward in electrical safety, offering a robust solution that aligns with the principles of live-dead-live testing:

- Enhanced Safety: Enables voltage verification without exposure to live components, significantly reducing the risk of accidents.

- Compliance with NFPA 70E: Facilitates adherence to safety standards by providing a reliable means to perform an absence of voltage test.

- Increased Efficiency: Streamlines the verification process, saving time and enhancing productivity without compromising safety.

Here's how the ChekVolt streamlines live-dead-live testing while enhancing safety, compliance, and efficiency:

- Live: Test on a known live circuit to verify multimeter functionality.

- Dead: Safely check for a de-energized state via ChekVolt's high-impedance test points, avoiding direct contact with potentially hazardous voltage.

- Live: Re-test on a live circuit to confirm multimeter functionality.

Tools & Qualification for Live-Dead-Live Testing

For a live-dead-live test, essential tools include a voltage tester or multimeter that's rated for the voltage of the system being tested, insulated gloves, and other personal protective equipment (PPE) as required by OSHA and NFPA 70E standards.

The electrician conducting the test must be qualified, meaning they have been trained to understand the equipment's operation and the hazards involved. OSHA and NFPA 70E standards require that these workers demonstrate proficiency in safe work practices and electrical safety principles, ensuring they can effectively identify and mitigate risks associated with electrical work.

Understanding Live-Dead-Live Testing

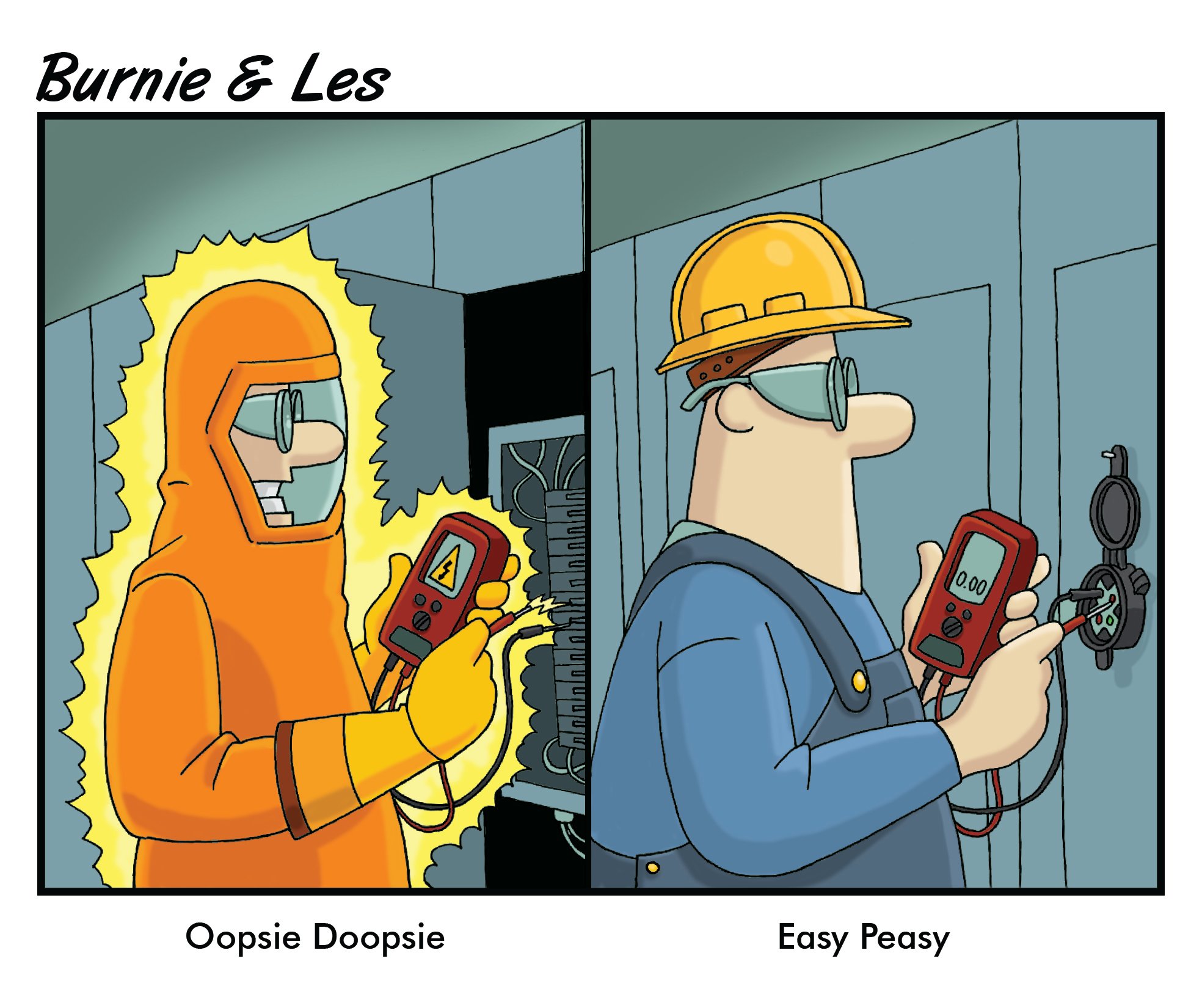

Live-dead-live testing is a three-step verification process designed to ensure that electrical circuits are properly de-energized before work begins, safeguarding workers from electrical hazards. The procedure involves:

Section 110.4(A)(5) - Operation Verification (Initial Live Test)

- Step 1: Live Test: Initially testing a known live source to confirm the testing device's functionality. Ensure your testing device is calibrated and operational by checking it against a known live source. Confirm the voltage level matches expectations for a live circuit.

Section 120.1(5) - Verification of an Electrically Safe Work Condition (Dead Test)

- Step 2: Dead Test: Verifying that the target circuit is de-energized. After ensuring all necessary lockout/tagout procedures have been followed, use the device to check the target circuit. Verify no voltage is present across all phases and potential neutral connections. Document the reading as part of your safety compliance records.

Section 110.4(A)(5) - Operation Verification (Re-confirmation Live Test)

- Step 3: Live Test: Re-testing on a known live source to ensure the testing device remains operational. Return to the known live source to re-test and confirm the device's functionality hasn't been compromised. This ensures the accuracy of your dead test and confirms the reliability of your testing equipment throughout the process.

The Importance of Live-Dead-Live Testing

Live-dead-live testing is crucial for electrical safety to verify the functionality of testing equipment and ensure circuits are de-energized before work begins. It prevents accidents by ensuring that the testing instrument is working properly before and after checking a circuit for voltage, thus adhering to NFPA 70E requirements for safe electrical work practices.

This procedure minimizes the risk of shock or arc flash, reinforcing the importance of verifying the absence of voltage to protect workers from electrical hazards. The significance of live-dead-live testing in electrical safety cannot be overstated:

- Preventing Electrical Accidents: It minimizes the risk of electric shock or arc flash by ensuring circuits are de-energized.

- Verifying Test Instrument Accuracy: Confirms the reliability of testing equipment, reducing the chances of false negatives or positives.

- Compliance with Safety Standards: Adheres to NFPA 70E 120.6, promoting a culture of safety and compliance within the workplace.

Consequences of Skipping Live-Dead-Live Testing

Skipping the live-dead-live test exposes electricians to severe risks, including electric shock, arc flash, and other electrical hazards. This omission could lead to working on an energized circuit under the assumption it's de-energized, significantly increasing the likelihood of accidents and injuries.

The live-dead-live test ensures the testing instrument's reliability and the circuit's safety status, serving as a critical safeguard in electrical work practices. Ignoring this step compromises personal safety and violates safety protocols designed to prevent electrical accidents. Omitting live-dead-live testing exposes workers to severe risks:

- Increased Risk of Electrocution: Working on assumed de-energized circuits that are live.

- Potential for Arc Flash Incidents: This could result in severe injuries or fatalities.

- Non-compliance Penalties: Violations of OSHA and NFPA standards can lead to substantial fines and legal ramifications.

Embrace the next step in electrical safety by requesting a ChekVolt sample today. Discover how this innovative tool can seamlessly integrate into your safety protocols, providing a safer, more efficient method for performing live-dead-live testing in full compliance with NFPA 70E standards. ChekVolt not only enhances safety by allowing voltage verification with the enclosure closed but also significantly boosts productivity by streamlining LOTO procedures.