Top 5 Features of Permanent Electrical Safety Devices (PESDs)

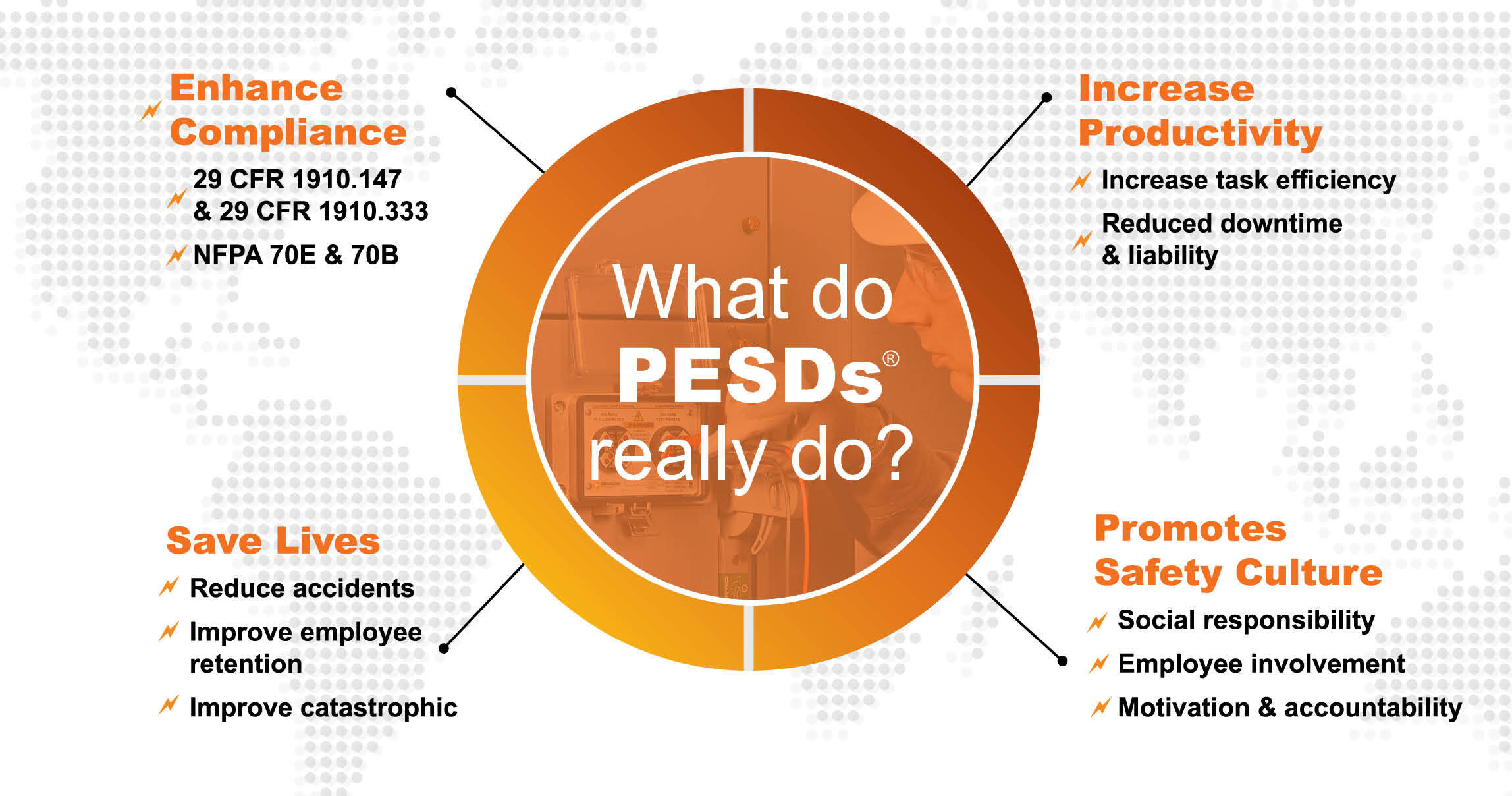

As we continue to recognize National Electrical Safety Month, it's the perfect time to focus on enhancing electrical safety in the workplace. Permanent Electrical Safety Devices (PESDs) are critical components in ensuring a safe working environment by providing reliable and efficient methods to manage electrical hazards. Here are the top five features of PESDs and how they contribute to a safer and more productive workplace.

1. Voltage Presence Indication

Voltage indicators are essential for immediately identifying the presence of voltage without opening an electrical panel. These devices, like the R-3W Voltage Indicator, utilize flashing or non-flashing LEDs to show when hazardous voltage is present. This feature reduces the risk of electrical shock and arc flash by allowing workers to verify voltage presence from outside the panel, enhancing compliance with NFPA 70E and OSHA standards.

2. Absence of Voltage Testing

Testing for the absence of voltage is a crucial step in ensuring an electrically safe work condition. Devices like the Safe-Test Point™ and ChekVolt® enable qualified personnel to perform this test using a standard multimeter. By providing high impedance protected test points, these PESDs allow for safe verification of de-energization from outside the enclosure, thereby reducing the need for direct exposure to electrical hazards.

3. Improved Productivity and Reduced Downtime

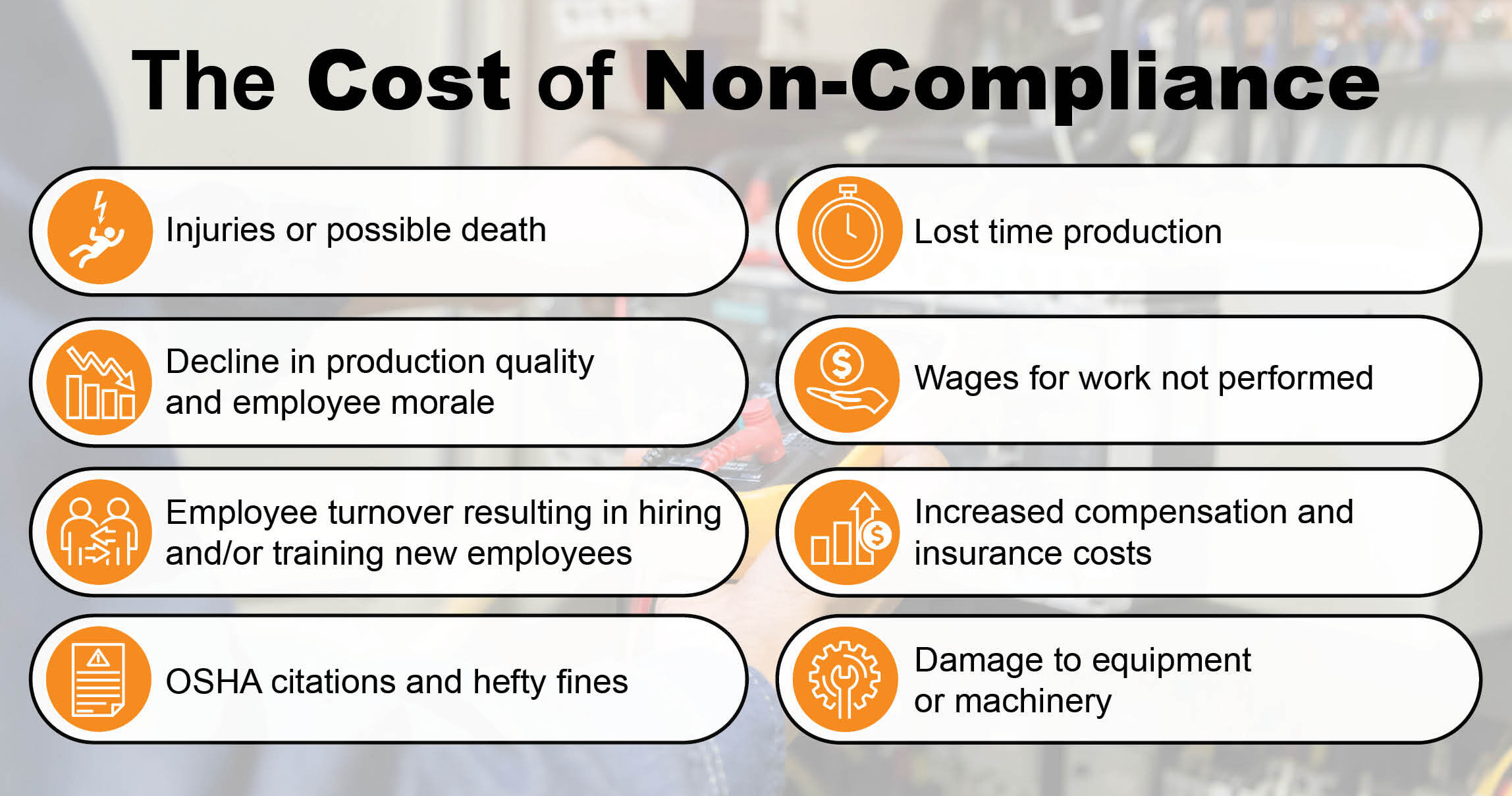

Implementing PESDs can significantly reduce downtime associated with Lockout/Tagout (LOTO) procedures. According to the U.S. Bureau of Labor Statistics, electrical injuries resulted in significant lost workdays and productivity. By using PESDs maintenance tasks are streamlined, allowing workers to quickly verify safety conditions and resume operations. This efficiency translates into considerable cost savings and improved operational uptime.

4. Mitigating Electrical Hazards

The primary purpose of PESDs is to mitigate risks associated with electrical maintenance tasks. By providing through-door access for voltage testing and indication reduce the likelihood of arc flash incidents and electrical shocks. These hazards are a leading cause of serious injuries and fatalities in the workplace. PESDs provide a safer method to manage these risks, fostering a culture of safety and responsibility.

5. Enhanced Compliance with Safety Standards

PESDs are designed to help organizations comply with stringent safety regulations such as NFPA 70E and OSHA 1910.147. These standards mandate specific procedures for locking out and tagging out electrical equipment to prevent accidental energization. PESDs like the Voltage Test Station, which combines a voltage indicator with a Safe-Test Point™ in one unit, make it easier to follow these procedures accurately and efficiently.

The Importance of Safety Culture and Compliance

Building a robust safety culture is essential for any organization. It involves not only adhering to regulatory standards but also promoting a mindset of proactive safety among employees. PESDs play a significant role in this by offering reliable tools that enhance safety protocols. A strong safety culture leads to fewer accidents, lower costs related to injuries, and higher employee morale and productivity.

To learn more about incorporating safety-by-design principles into your electrical safety programs, download our eBook: Electrical Safety-by-Design: Save Lives. Increase Productivity. This comprehensive guide provides insights into enhancing compliance, reducing risks, and improving productivity through innovative safety solutions.

By prioritizing electrical safety and integrating advanced PESDs into your operations, you can create a safer, more efficient workplace that not only meets but exceeds safety standards.

.jpg?width=2296&height=1208&name=PESD%20ebook%20social%20media%202403%20(1).jpg)