The Importance of Testing for Absence of Voltage

Verifying the absence of voltage is a critical safety measure, particularly before maintenance or servicing tasks. Traditional methods involve multimeters, but the integration of Permanent Electrical Safety Devices (PESDs) like ChekVolt and Safe Test Point has revolutionized this process. This blog highlights the importance of PESDs in ensuring safety and compliance with NFPA 70E and OSHA standards.

Understanding the Need for Absence of Voltage Testing

The absence of voltage testing is critical in ensuring that electrical circuits are de-energized before any maintenance or repair work begins. This process is a key component of Lockout/Tagout (LOTO) procedures, safeguarding workers from the unexpected energization or startup of machinery and equipment.

Testing for the absence of voltage typically involves using hand-held testing equipment or multimeters. A qualified person must perform a series of checks to confirm that the circuit is de-energized. This includes verifying that the test instrument functions correctly before and after testing the circuit.

With PESDs, absence of voltage testing becomes a streamlined process. ChekVolt and Safe Test Point allow testing outside the electrical panel, reducing the need for direct contact with live components. This minimizes the risk of electrical hazards and ensures compliance with safety standards without compromising productivity.

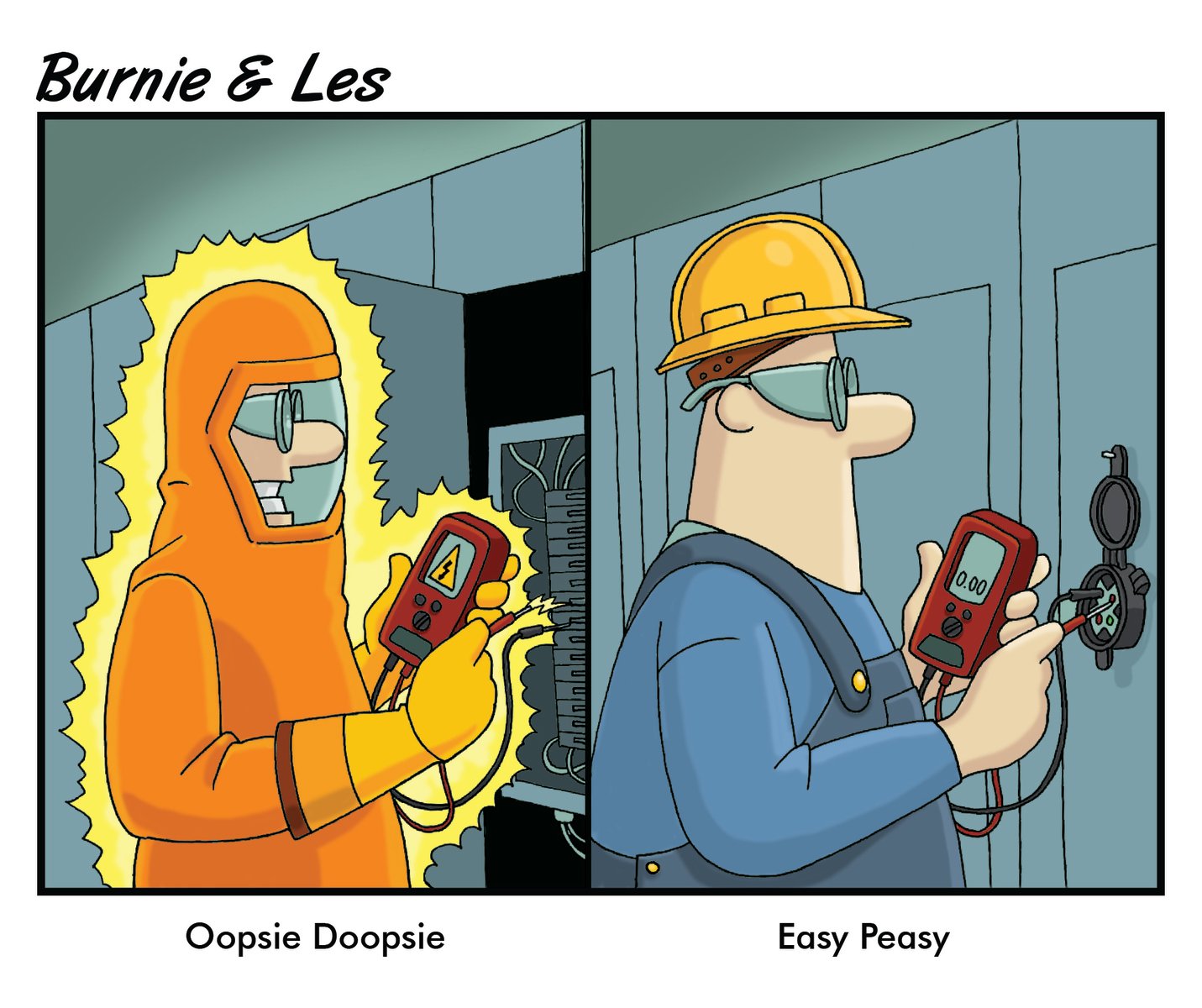

The Risks of Absence of Voltage Testing Without PESDs

Testing for the absence of voltage without PESDs carries inherent risks. Technicians must expose themselves to potential electrical hazards by opening electrical panels and using handheld test equipment. This exposure increases the risk of electrical shock and arc flash incidents. Personal Protective Equipment (PPE) is required but does not eliminate the risk; only mitigates it.

Routine maintenance tasks without PESDs involve verifying the multimeter's functionality, testing for voltage presence, and re-verifying its functionality post-testing. Each step must be performed meticulously to ensure safety, often under the pressure of operational downtime.

NFPA 70E and OSHA standards mandate rigorous procedures for verifying the absence of voltage. Compliance requires a methodical approach, including appropriate PPE, which can be cumbersome and time-consuming, leading to potential non-compliance and increased danger.

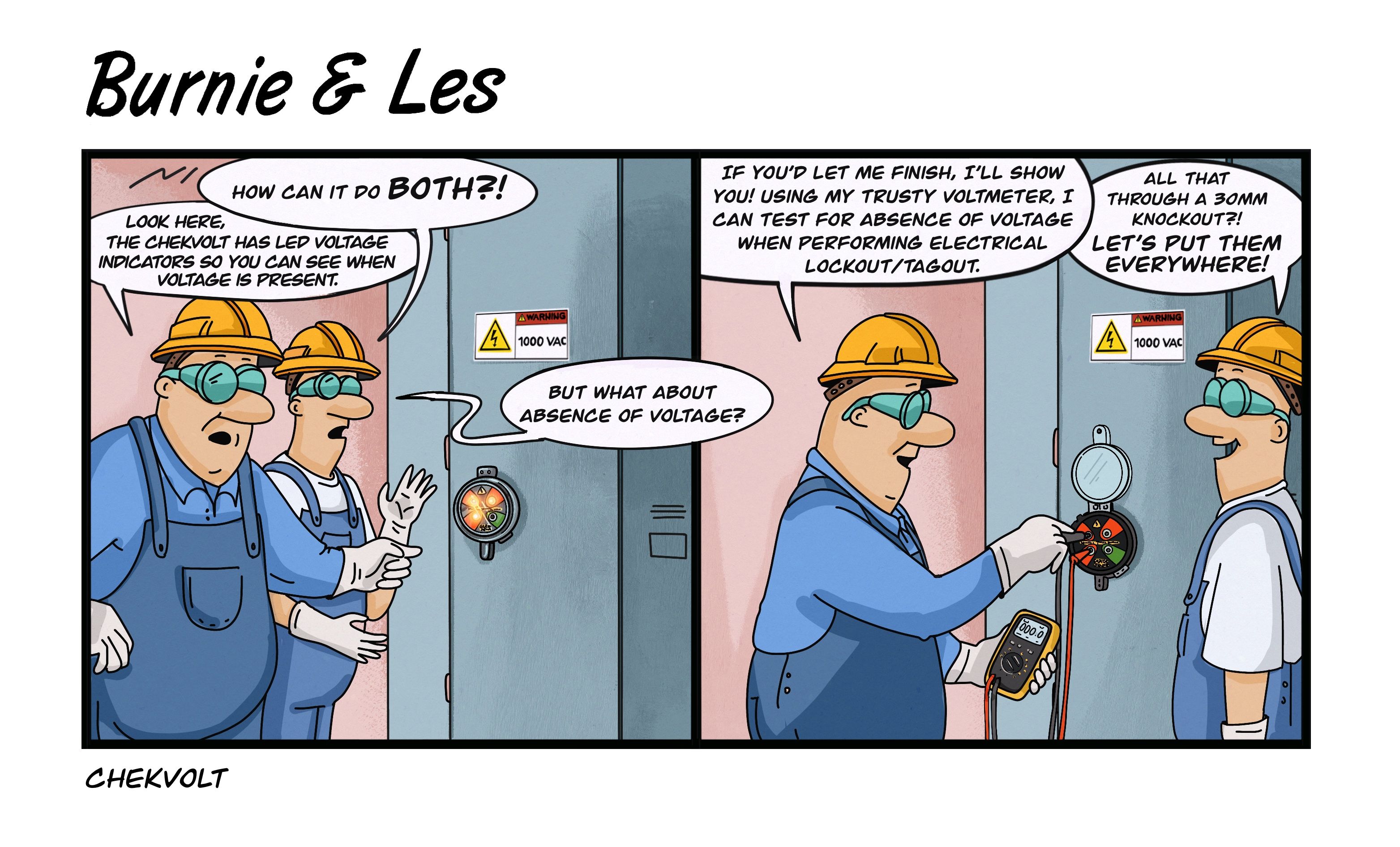

ChekVolt: A Comprehensive Safety Solution

ChekVolt stands out as a premier PESD, offering dual functionality. It visually indicates voltage presence through LED lights and enables a safe and reliable absence of voltage testing method. The device’s high impedance-protected test points are compatible with standard multimeters, so electricians can perform tests confidently and competently.

- Safety: ChekVolt’s touch-safe test points reduce the need for direct contact with live components, minimizing the risk of electrical hazards.

- Efficiency: By indicating voltage presence and allowing for the absence of voltage testing, ChekVolt streamlines safety checks, leading to faster and safer LOTO procedures.

- Compliance: Designed to meet safety standards, ChekVolt helps adhere to NFPA 70E and OSHA regulations, ensuring a safe and compliant workplace.

Safe-Test Point: Simplifying Safety Checks

Safe-Test Point simplifies verifying voltage's absence. Its user-friendly design and touch-safe features ensure qualified personnel can conduct tests with minimal exposure to risk.

- Ease of Use: With its straightforward design, Safe-Test Point can be used by qualified electricians of all skill levels, promoting a safety culture across the board.

- Productivity: By reducing the complexity of safety checks, Safe-Test Point contributes to quicker maintenance routines, enhancing overall productivity.

- Innovation: Safe Test Point represents the next step in PESD technology, offering a simple yet effective solution for electrical testing. It is a testament to safety innovation.

The Impact on Safety and Productivity

The integration of ChekVolt and Safe-Test Point into electrical safety programs has a profound impact:

- Reduced LOTO Times: The streamlined process can reduce traditional LOTO procedures by up to 40 minutes, translating to significant time savings.

- Enhanced Safety: The risk of electrical incidents is greatly diminished by the high impedance protected test points, creating a safer work environment for electricians.

- Increased Compliance: With these PESDs, companies can ensure that their safety protocols meet or exceed industry standards.

Elevating Electrical Safety: The Essential Role of PESDs in Voltage Verification

Using PESDs like ChekVolt and Safe-Test Point is a game-changer in the electrical industry. They offer a safer, more efficient, and compliant method for absence of voltage testing. The case for their integration is compelling for those familiar with PESDs and those new to the concept. They are not just tools but vital components of a robust electrical safety program.

While voltage indicators serve as an initial alert to the presence of voltage, devices like ChekVolt and Safe-Test Point are indispensable for confirming a de-energized state. Together, they form a robust safety system that protects workers from electrical hazards and supports compliance with safety standards.

Incorporating PESDs into LOTO procedures is wise for organizations looking to implement or enhance their electrical safety protocols. By doing so, they safeguard their employees and demonstrate a commitment to maintaining a safety culture. Request a sample PESD today!