Streamlining Your LOTO Procedures: How Much Time and Money Are You Losing?

Lockout/Tagout (LOTO) procedures are essential for ensuring the safety of workers during maintenance and repair activities on industrial equipment. However, they can also be time-consuming, significantly impacting productivity. Understanding how much time is spent on LOTO procedures each year and the associated costs can help companies identify areas for improvement.

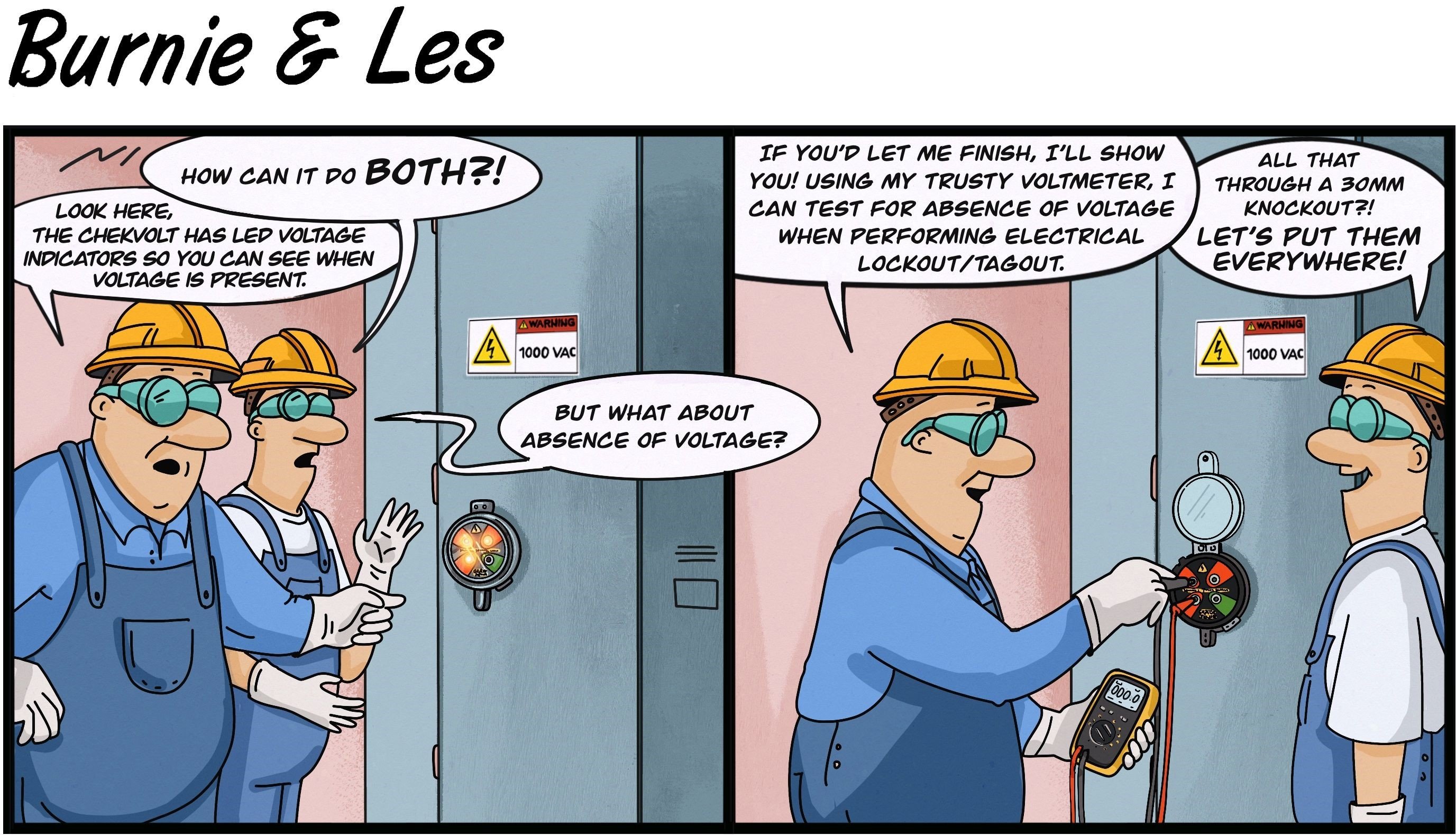

This blog explores the time and cost implications of LOTO procedures in the United States, highlights the efficiency of Permanent Electrical Safety Devices (PESDs) like ChekVolt, and discusses the importance of staying compliant with the latest OSHA and NFPA 70E standards.

Time Spent on LOTO Procedures

According to industry estimates, each LOTO procedure can take anywhere from 45 minutes to an hour, depending on the complexity of the machinery and the thoroughness of the safety checks. Considering that many companies perform multiple LOTO procedures daily, the time adds up quickly.

- Statistics: On average, manufacturing plants in the U.S. perform around 10-20 LOTO procedures per day. This translates to approximately 300-600 hours spent annually on LOTO procedures per facility.

Cost of LOTO Procedures

The cost associated with LOTO procedures includes both direct labor costs and the indirect costs of downtime. For a medium-sized manufacturing plant, the combined cost can be substantial.

- Estimated Costs: Assuming an average labor cost of $50 per hour, the direct labor cost for LOTO procedures alone can reach $15,000-$30,000 annually per facility. When factoring in downtime costs, the total cost can exceed $100,000 annually.

Reducing LOTO Procedure Times

ChekVolt, an advanced PESD, significantly reduces the time required for LOTO procedures. By allowing for safe and compliant absence of voltage testing with multimeters, ChekVolt can cut LOTO procedure times from 45-60 minutes to just 5-10 minutes.

- Efficiency Gains: Implementing ChekVolt can save approximately 35-50 minutes per LOTO procedure. Over a year, this can result in a time savings of 175-350 hours per facility.

Enhancing Safety

ChekVolt features redundant LED voltage indicators and high impedance-protected test points, providing clear visual indications of voltage presence or absence. This reduces the risk of electrical hazards, such as arc flash and electric shock, during maintenance activities.

Ensuring Compliance

ChekVolt helps companies stay compliant with OSHA and NFPA 70E standards by providing a reliable and safe method for performing LOTO procedures. This compliance is crucial for avoiding fines and ensuring the safety of workers.

Key Changes in NFPA 70E 2024

The 2024 edition of NFPA 70E includes several important updates aimed at improving electrical safety in the workplace. Some of the key changes include:

- Arc Flash Hazard Analysis: Enhanced requirements for conducting arc flash hazard analysis to ensure accurate risk assessments.

- Risk Assessment Procedures: Updated guidelines for performing comprehensive risk assessments to identify and mitigate electrical hazards.

- Training Requirements: Expanded training requirements for qualified personnel to ensure they are equipped with the knowledge and skills needed to perform electrical work safely.

Tips for Staying Compliant

To stay compliant with the latest NFPA 70E standards, companies should:

- Regularly Review and Update Procedures: Ensure that LOTO procedures and electrical safety protocols are reviewed and updated regularly to reflect the latest standards.

- Invest in Training: Provide ongoing training for employees to keep them informed about the latest safety practices and regulatory requirements.

- Utilize Advanced Safety Devices: Implement advanced safety devices like ChekVolt to enhance the efficiency and safety of LOTO procedures.

LOTO procedures are critical for ensuring worker safety during maintenance activities, but they can be time-consuming and costly. By implementing advanced safety devices like ChekVolt, companies can significantly reduce LOTO procedure times, enhance safety, and ensure compliance with OSHA and NFPA 70E standards.

As we move through 2024, it's essential for companies to stay informed about the latest regulatory changes and continuously seek ways to improve their safety practices. ChekVolt offers a reliable solution for achieving these goals, ultimately leading to a safer and more productive work environment.

As we continue to explore enhancing electrical safety, it’s clear that advancements in technology and renewable energy bring both opportunities and challenges. Ensuring the safety of higher voltage DC systems is crucial as we embrace solar power and electric vehicles.

To explore these emerging issues and learn about the latest advancements in electrical safety, join us for an insightful webinar on "Enhancing Electrical Safety for Higher Voltage DC Systems," presented by Kevin Zamzow.

Don’t miss this opportunity to stay ahead in the field—register now for the webinar on Tuesday, June 25 at 10am, and be part of the conversation shaping the future of electrical safety.