How to Launch a Predictive Maintenance Program Without Breaking the Budget

Predictive maintenance is changing how facilities manage equipment health and operational performance. Instead of reacting to failures or relying only on scheduled maintenance, modern predictive strategies use real-time sensor data to detect early warning signs before breakdowns occur. This shift helps reduce unplanned downtime, extend asset life, and improve maintenance planning.

Not long ago, predictive maintenance felt out of reach for many teams. The systems were expensive, the software was overwhelming, and you often needed a specialist just to interpret the data. That has changed. With modern sensors and user friendly dashboards, facilities can now begin gathering meaningful machine health data without the massive upfront investment that used to be required.

The goal is the same across maintenance, reliability, and EHS teams: reduce downtime, catch issues earlier, and make better decisions. The good news is that you can begin with a small, affordable foundation that delivers real impact.

Here is a practical approach to launching a predictive maintenance program that fits your budget and delivers real results.

1. Start by Identifying the Assets That Drive the Most Downtime

Every facility has a few assets that seem fine until they suddenly are not. These machines often give small indicators long before failure, including increasing vibration, temperature rise, hot spots, or changes in mechanical load. Focusing on these high risk assets first is the fastest way to see the value of machine health monitoring.

It is also the most practical approach. Many teams run into avoidable issues when they try to monitor everything at once. Starting with a small group of critical assets keeps the scope manageable and helps avoid the common condition monitoring mistakes that can slow progress later.

The goal is simple. Let sensors pick up the subtle shifts that humans cannot catch just by feeling a motor casing or listening to a fan. These early signals are often the difference between a quick repair and unplanned downtime that affects production schedules.

2. Use Sensors That Give Instant Visibility Without Complicating Workflows

Modern machine health monitoring works best when it is simple. Wireless sensors make it easy to track vibration, temperature, and other indicators that influence asset reliability. They install quickly, do not require special wiring, and begin sending real time data within minutes.

Choosing technology that is easy to use matters. Predictive maintenance efforts often stall when tools feel complicated or when technicians cannot interpret the data. Clear visualization, intuitive alerts, and straightforward asset health indicators help teams stay confident and engaged.

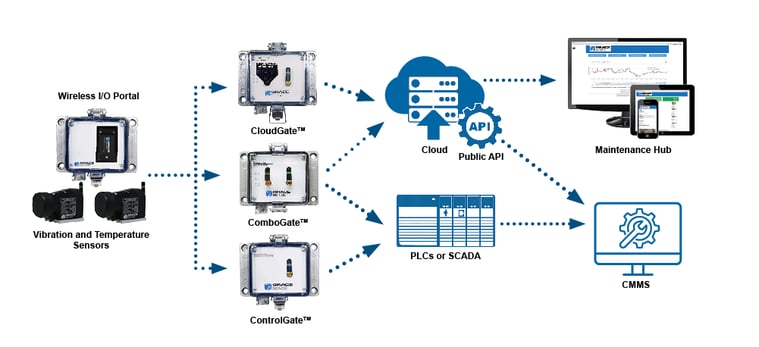

Wireless sensors also support visibility across the entire equipment journey. When data moves seamlessly from the sensor to the dashboard, as it does within the GraceSense system, teams can understand what is happening, why it is happening, and how quickly they need to respond.

The sensor to system workflow illustrates this path well, showing how each step supports faster, more informed decision making. This is predictive maintenance designed to feel practical, approachable, and easy to trust.

3. Use Software That Helps Teams Respond Faster Instead of Slowing Them Down

Traditional predictive maintenance software was often the most expensive and complicated part of the entire program. Many platforms required significant training or added layers of data analysis that slowed teams down. Today’s dashboards are different. They focus on clarity, fast insight, and user friendly navigation so that the information feels actionable instead of intimidating.

Modern platforms also help teams understand what the data actually means. Instead of presenting only raw vibration charts, modern systems translate data into recognizable fault patterns linked to issues like misalignment or bearing wear. By analyzing vibration behavior and tying it to clear alerts, technicians get the insights they need without relying on a vibration expert to interpret raw FFT data.

Accessible, user-friendly software makes predictive maintenance easier to adopt and scale. Clear insights help teams spot issues early and respond before failures occur.

4. Keep Your Launch Affordable With a Pilot Program Approach

Predictive maintenance becomes much more attainable when the initial investment is small and structured. A pilot program or starter kit gives facilities an easy way to begin without committing to a full rollout right away.

Why teams start with the GraceSense Pilot Program

The GraceSense Pilot Program gives facilities an easy way to begin predictive maintenance without building a complex system. It includes:

- Wireless vibration and temperature sensors

- A plug and play gateway

- Cloud dashboard access and optional data delivery directly into your PLCs or SCADA

The program also provides site audit and commissioning support, which helps teams validate RF coverage, streamline installation, and get comfortable with the system quickly. This approach removes the biggest barriers that typically slow down predictive maintenance adoption.

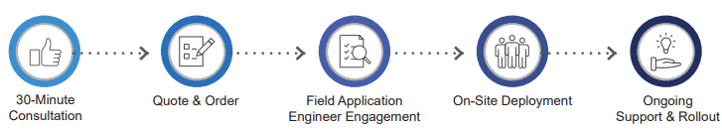

A simple, guided rollout process

Most teams see meaningful insights within the first few weeks of a pilot. When leadership sees real time data preventing failures and reducing downtime, expanding the program becomes an easy decision.

5. Measure ROI Early by Understanding What Equipment Problems Really Cost

Predictive maintenance delivers ROI faster than almost any other reliability strategy. Industry studies consistently show that early detection can reduce unplanned downtime by up to 30%, extend asset life by 20 to 40%, and lower maintenance costs by up to 25%. In many cases, preventing a single motor failure or catching an overheating bearing in time covers the entire cost of a pilot program or starter kit.

How predictive maintenance improves OEE

OEE, or Overall Equipment Effectiveness, improves when availability improves, and unplanned downtime is one of the biggest drains on OEE. Research from the manufacturing and automotive sectors shows that even a 1% improvement in availability can translate into tens of thousands of dollars per year for mid-sized production lines.

Because predictive maintenance reduces downtime events before they escalate, teams often see:

- Reduced downtime: Every avoided breakdown saves thousands of dollars per hour in lost production.

- Boosted throughput: Maintain output speed and consistency without expensive capital investment.

- Improved quality: Lower scrap and rework rates to save materials and labor.

This is why predictive monitoring directly increases OEE without major process changes.

Real-world impact from GraceSense users

One GraceSense user shared that once they started monitoring their equipment consistently, they finally saw the early indicators on their crane, conveyors, and press bearings that had been driving unexpected failures and slowing production. Early visibility let their team get ahead of the problem and keep production running instead of reacting after a failure.

6. Scale Naturally as Your Team Grows More Confident

A predictive maintenance program does not need to be perfect on day one. What matters is building a foundation that your team can grow with. As you build confidence with early insights, you can expand your sensor network, adjust alert thresholds, integrate with your CMMS, and refine how your reliability and maintenance teams use data. The transition from basic monitoring to a more mature strategy is smoother when it begins with a clear focus rather than an overwhelming rollout.

Teams that scale slowly avoid the issues that commonly derail condition monitoring programs. By starting with fundamentals and then expanding based on proven value, predictive maintenance becomes a long term reliability strategy instead of a short lived experiment.

Where to Go From Here

And there you have it. Predictive maintenance doesn’t have to be expensive or complicated. With the right tools and a focused starting point, your team can reduce downtime, improve asset reliability, and build a stronger maintenance strategy for the long term. The GraceSense Pilot Program gives facilities a practical and affordable way to begin collecting real time data and uncovering trends that would otherwise remain hidden. It is accessible, scalable, and designed to move teams from reacting to preventing.

Ready to transform your predictive maintenance strategy? Experience the benefits firsthand with our Pilot Program. And with our Grace Guarantee, your investment is risk-free: Love it or return it! If you're not satisfied within 90 days, we'll provide a full hardware refund.

To safer, smarter operations,