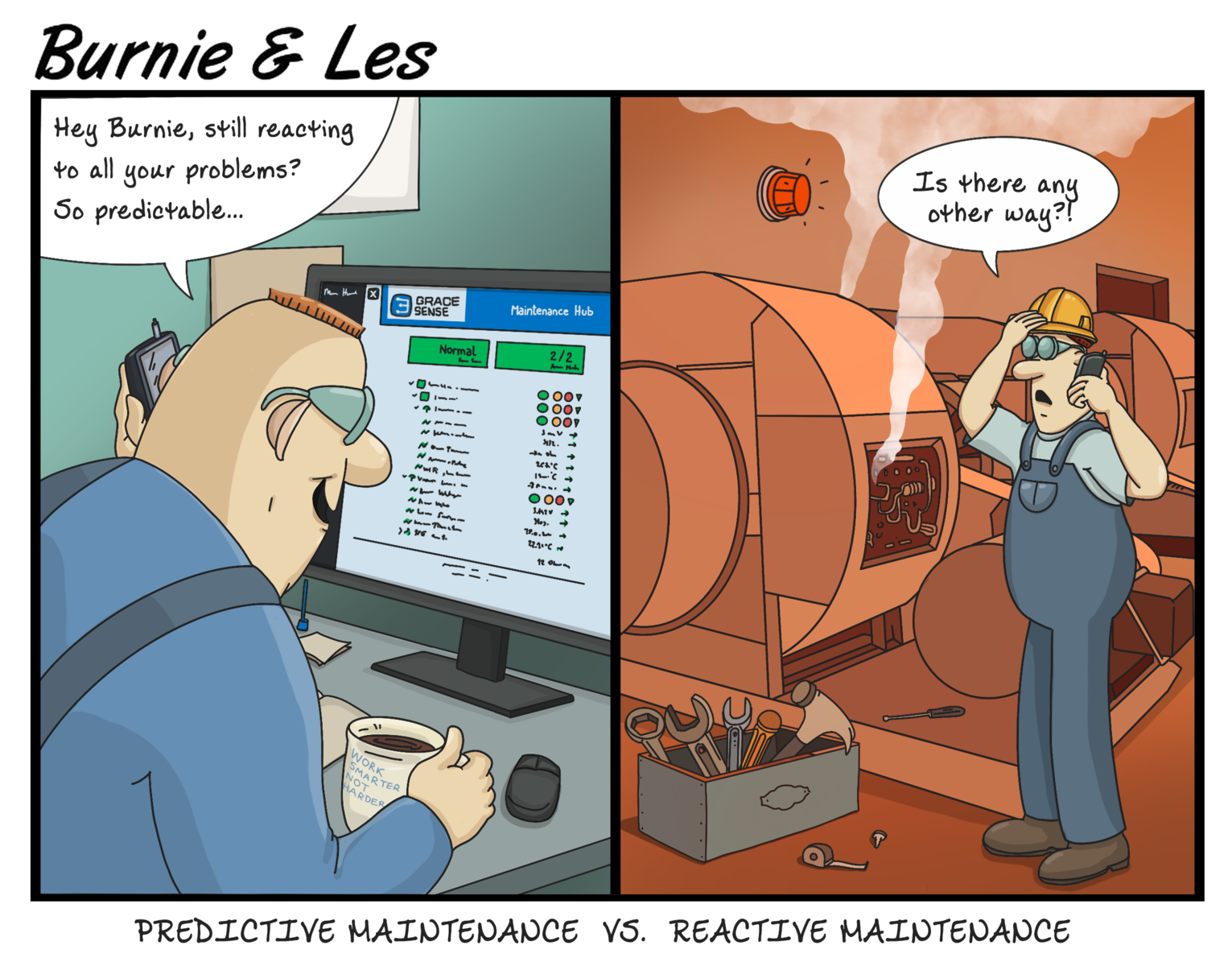

In today’s industrial landscape, predictive maintenance is no longer a luxury; it’s a necessity. But many facilities struggle to make it work in practice. Why? Because they’re missing the foundation: machine health monitoring.

While predictive maintenance promises to reduce unplanned downtime and cut costs, the reality is that without the right condition monitoring tools, even the best maintenance strategies fall flat. If you can't detect early-stage failures with confidence, you can't predict what’s coming next. That’s where GraceSense comes in.

The Role of Machine Health Monitoring in Predictive Maintenance

Machine health monitoring involves collecting and analyzing real-time data on equipment condition, such as vibration, temperature, and runtime, to detect issues before they become failures. But it’s not just about gathering data. It’s about making it actionable.

With GraceSense, you get wireless vibration monitoring and temperature sensors that stream data continuously to the Maintenance Hub dashboard, where alerts and trends help your team prioritize what matters most. The system enables real-time asset monitoring and simplifies predictive maintenance, even across multiple sites.

Why Predictive Maintenance Fails Without the Right Data

Many predictive maintenance programs begin with good intentions but often stall due to complexity or a lack of in-house expertise.

- Manual rounds and route-based vibration analysis require certified analysts, who are in short supply.

- Most systems produce too much raw data and not enough insight.

- Integrating with existing PLCs or CMMS platforms can often be a headache.

In short, predictive maintenance fails without machine health monitoring that is scalable, automated, and easy to integrate.

Automating Vibration Analysis Without a Certified Analyst

GraceSense helps teams overcome the skills gap by automating tasks that previously required a trained expert. The platform’s automated defect detection utilizes a library of 19 predefined fault models to classify problems such as bearing wear, imbalance, and misalignment, eliminating the need for a vibration analyst.

Instead of raw FFT plots, teams see alerts like: "Stage-2 bearing wear detected on Motor A102—repair within 10 days." This gives technicians the power to act fast, without needing to interpret complex waveforms.

Wireless Condition Monitoring with GraceSense™

GraceSense’s IIoT condition monitoring architecture combines:

- VBTx vibration and temperature sensors with IP69K ratings for harsh environments

- Flexible gateways (CloudGate™, ControlGate™, ComboGate™) that support both cloud and control network communication

- A browser-based Maintenance Hub for configuration, visualization, and automatic work order creation

Everything is designed for fast deployment, easy scaling, and seamless integration with platforms like Fiix, SCADA, or MODBUS.

Scalable Predictive Maintenance That Actually Works

With traditional tools, it's challenging to implement predictive maintenance across a large facility or multiple sites. GraceSense makes it simple by delivering:

- Plug-and-play hardware

- Standardized alert logic

- Cloud or on-premises flexibility

- No reliance on a vibration analysis expert

It’s a smarter, more scalable alternative to conventional vibration programs.

Reduce Unplanned Downtime with the Right Tools

When your assets are being monitored in real time, there are no surprises. That’s why machine health analytics is the true starting point for any predictive maintenance initiative. The earlier you catch problems, the cheaper and safer they are to fix. GraceSense™ gives you:

- Actionable insights instead of raw data

- Fewer emergency repairs

- Fewer blind spots across your plant

- More uptime, less stress

Predictive Maintenance Starts Here

If your predictive maintenance strategy is stuck, it might not be your team—it might be your tools.

GraceSense Machine Health Monitoring Solutions provide real-time machine data and actionable alerts, enabling you to reduce downtime, streamline maintenance, and extend the life of your equipment. You don’t need a team of analysts. You just need the right system.

Ready to see it in action? 👉 Book a demo and explore our Ultimate Guide to Condition Monitoring.

We’re unpacking five condition-monitoring pitfalls—and the GraceSense™ fixes—in a live webinar this month: “Stop the Surprise Shutdowns: 5 Condition-Monitoring Mistakes to Fix in 2025”. Join our reliability pros for a deeper dive, real-time Q&A, and a practical pilot roadmap.

Save your seat here ➜ Webinar Registration

Stay SAFE, and have a GREAT week!