What Is the Main Function of a Continuous Vibration Monitor?

In industries where equipment failure can result in serious consequences, such as aviation or oil and gas, continuous vibration monitoring plays a vital role. By utilizing a continuous vibration monitor, maintenance teams can receive fast notifications when problems arise, enabling them to respond quickly and prevent downtime. This blog explores the main functions of a continuous vibration monitor and highlights its benefits in optimizing maintenance practices.

A continuous vibration monitor serves as a valuable tool for real-time monitoring of equipment vibrations. It detects and measures vibrations continuously, providing crucial data to assess the health of machines and identify potential issues before they escalate. By utilizing advanced sensors and analytics, continuous vibration monitors enable proactive maintenance and ensure the smooth operation of critical equipment.

Unlocking Proactive Maintenance with a Continuous Vibration Monitor

A continuous vibration monitor is a powerful tool that enables maintenance teams to adopt a proactive approach to equipment maintenance. By continuously monitoring vibrations in machinery, these devices provide real-time data and insights that help identify potential issues before they escalate into costly failures.

With the ability to detect anomalies and abnormal vibration patterns, continuous vibration monitors play a vital role in maximizing equipment uptime, extending asset life, and reducing maintenance costs. In this section, we will explore the key benefits and functionalities of continuous vibration monitors in unlocking proactive maintenance strategies:

- Continuous vibration monitoring enables maintenance teams to shift from reactive to proactive maintenance strategies.

- By continuously monitoring vibration levels, the monitor detects deviations from normal patterns, indicating potential faults or failures.

- Early detection of issues allows maintenance teams to take immediate action, preventing costly breakdowns and reducing downtime.

Taking Control of Vibration Data with a Continuous Vibration Monitor

Effectively managing and interpreting vibration data is crucial for successful condition monitoring and maintenance. A continuous vibration monitor provides a comprehensive solution to capture and analyze vibration data, enabling maintenance teams to take control of their predictive maintenance programs.

By utilizing advanced data analytics and visualization tools, these monitors allow users to gain deep insights into equipment health and make informed decisions about maintenance actions. In this section, we will explore how a continuous vibration monitor empowers maintenance teams to take control of vibration data for enhanced maintenance strategies:

- A continuous vibration monitor collects and analyzes vibration data in real-time, providing valuable insights into machine health.

- The monitor utilizes advanced algorithms to analyze vibration patterns, identifying anomalies or trends that could indicate impending failures.

- Maintenance teams can access the collected data and gain a comprehensive understanding of equipment performance and potential risks.

Benefits of Using the Continuous Vibration Monitor

Implementing a continuous vibration monitor brings a multitude of benefits to maintenance operations, leading to improved equipment reliability and optimized maintenance practices. These monitors offer valuable insights into machine health, enabling timely interventions and proactive maintenance actions. In this section, we will explore the key benefits that organizations can derive from utilizing continuous vibration monitors:

- Timely notifications: Maintenance teams receive fast notifications when the state of a problem forms, enabling a quick response.

- Proactive maintenance: Early detection of faults allows maintenance activities to be scheduled and executed proactively, minimizing downtime.

- Improved safety: Continuous vibration monitoring helps identify potential hazards and mitigates safety risks.

- Cost savings: By preventing unexpected breakdowns and optimizing maintenance schedules, businesses can reduce repair and replacement costs.

Why Monitoring Vibrations with a Continuous Vibration Monitor is a Must

Monitoring vibrations with a continuous vibration monitor is essential for industries where equipment failure can have severe consequences, such as aviation, oil and gas, manufacturing, and power generation. These monitors provide a proactive approach to maintenance, enabling organizations to detect potential faults and abnormalities before they lead to costly downtime or safety incidents.

Key reasons why monitoring vibrations with a continuous vibration monitor is a must include:

- Enhanced equipment reliability: Continuous monitoring of vibrations allows for the early detection of issues, preventing equipment failures and extending the lifespan of critical assets.

- Improved productivity: Minimizing downtime and unplanned maintenance improves overall operational efficiency and productivity.

- Data-driven decision-making: Access to real-time vibration data empowers maintenance teams to make informed decisions based on accurate and reliable information.

How to Ensure Safety and Reduce Downtime with a Continuous Vibration Monitor

Safety and downtime are significant concerns for industries that rely on the continuous and reliable operation of their equipment. A continuous vibration monitor plays a vital role in ensuring safety by providing early detection of faults and abnormalities, allowing maintenance teams to address issues promptly. Additionally, these monitors help reduce downtime by enabling proactive maintenance actions and minimizing the risk of unexpected breakdowns.

Key strategies to ensure safety and reduce downtime with a continuous vibration monitor include:

- Proper installation and calibration: Follow manufacturer guidelines to ensure the accurate installation and calibration of the monitor.

- Regular data analysis: Regularly review and analyze vibration data to identify trends and patterns, allowing for proactive maintenance planning.

- Integration with maintenance programs: Integrate the continuous vibration monitor with existing maintenance programs and workflows to maximize its effectiveness.

- Ongoing training and education: Provide training to maintenance teams on how to interpret vibration data and take appropriate actions.

A continuous vibration monitor is a powerful tool that empowers maintenance teams to detect issues early, prevent equipment failures, and optimize maintenance practices. By implementing continuous vibration monitoring, businesses can enhance equipment reliability, improve safety, and reduce downtime. Embracing this technology is essential for industries where equipment failure can have severe consequences. Stay ahead of potential issues with the continuous vibration monitor and unlock the benefits of proactive maintenance.

Frequently Asked Questions

Q: How does a vibration detection device work?

A: Vibration detection devices, such as continuous vibration monitors, utilize sensors to measure vibrations in equipment. These sensors convert mechanical vibrations into electrical signals, which are then processed and analyzed to determine the health and condition of the machine. By monitoring the amplitude, frequency, and other characteristics of vibrations, the device can detect anomalies and potential faults.

Q: How do you use a vibration analyzer?

A: A vibration analyzer is a tool used to analyze vibration data collected by sensors. It allows maintenance teams to interpret and understand the vibration patterns of machinery. By connecting the analyzer to the sensors or data logging systems, users can assess the vibration levels, identify abnormal patterns, and make informed decisions about maintenance actions.

Q: What are the benefits of vibration sensors?

A: Vibration sensors offer several benefits in condition monitoring and maintenance practices. These include:

- Early fault detection: Vibration sensors can detect subtle changes in vibration patterns, enabling the early identification of potential issues before they escalate into major problems.

- Predictive maintenance: By continuously monitoring vibrations, sensors provide data that helps predict the remaining useful life of equipment components, allowing for proactive maintenance scheduling.

- Improved equipment reliability: Regular monitoring and analysis of vibrations help ensure optimal performance and extend the lifespan of machinery, reducing the risk of unexpected breakdowns.

- Cost savings: By preventing equipment failures and optimizing maintenance practices, businesses can reduce repair and replacement costs while maximizing equipment uptime and productivity.

Q: What does vibration do for you?

A: Vibration in machinery can serve as an early warning sign of potential issues or faults. Monitoring and analyzing vibrations provide valuable insights into the health and condition of equipment, enabling maintenance teams to take proactive actions and prevent unplanned downtime. By understanding the vibrations, maintenance professionals can identify abnormal patterns, detect imbalances, misalignments, or worn components, and make informed decisions on maintenance activities.

Q: What is the difference between a vibration meter and a vibration analyzer?

A: A vibration meter is a handheld device used to measure vibration levels in machinery. It provides real-time readings of vibration amplitude, frequency, and other parameters at a specific moment. A vibration analyzer, on the other hand, is a more advanced tool that can perform in-depth analysis of vibration data collected from sensors or data logging systems. It allows users to analyze vibration spectra, identify patterns, and detect abnormalities, providing a more comprehensive understanding of machinery health.

Learn more about condition monitoring in our Ultimate Guide.

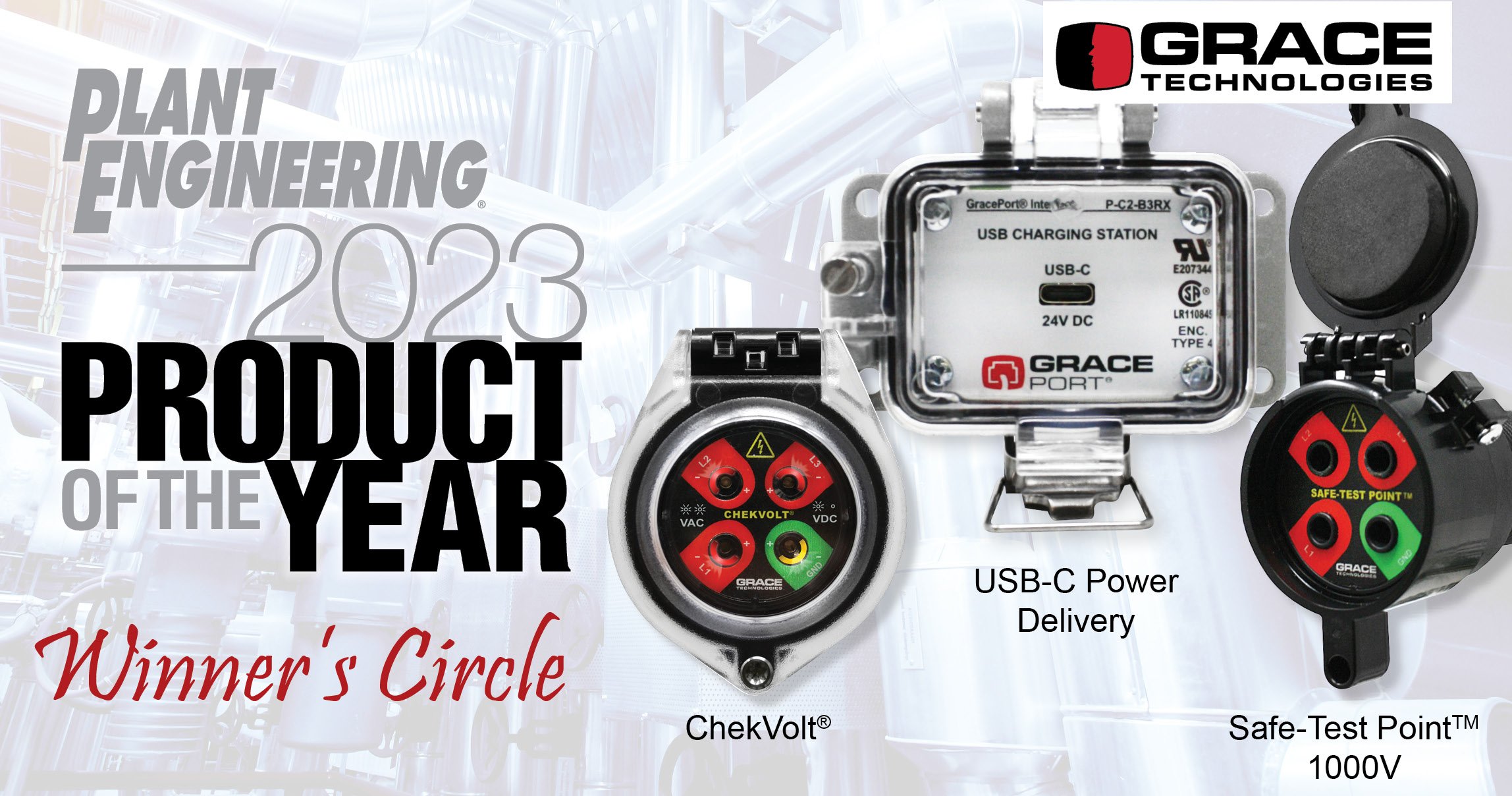

We are thrilled to announce that Grace Technologies has won multiple Plant Engineering Magazine's 2023 Product of the Year awards! ChekVolt® - Winner in Safety & Security, GracePort® USB-C Power Delivery - Winner in Power, & Safe-Test Point™ 1000V - Winner in Safety & Security.

Thank you to all our customers and supporters who voted! Request your ChekVolt product sample now and experience award-winning safety.