predict failures. prevent downtime. Enhance Safety.

our suite of smart devices provide advanced analytics with deep insights about machine health to prevent unplanned downtime

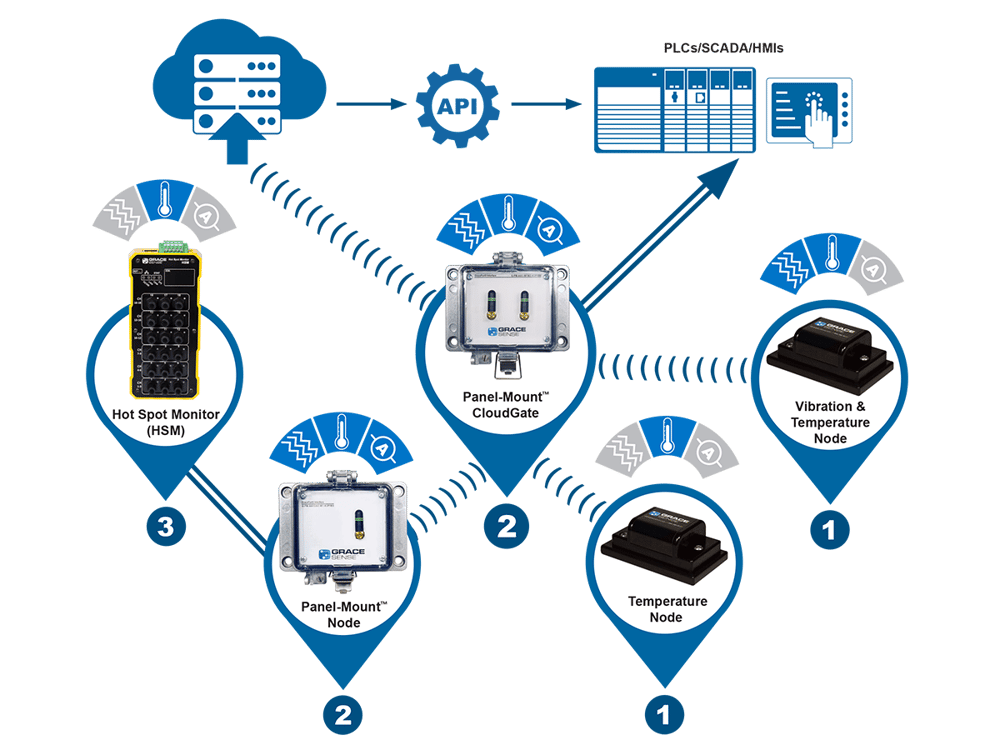

gracesense predictive maintenance system

vibration & Temperature node

Wireless Sensor that monitors vibration and temperature on any rotating equipment. Multiple mounting options available.

Panel-mount node or cloudgate

Configurable hardware with a wide variety of inputs, transducers, radios and power options that are mounted in an environmentally rated housing.

hot spot monitor

Non-conductive temperature monitoring device that detects potential hot spots and alerts personnel of temperature abnormalities in electrical equipment.

maintenance hub

Intuitive web application that provides real-time asset status using dashboards, plot trends and analytics that provide system information, reports and issues alerts.

ABOUT GRACESENSE

The entire GraceSense Predictive Maintenance System encompasses a wide array of asset health monitoring smart devices utilizing IIoT and allows users to view real-time analytics through an intuitive web-based app. GraceSense was first introduced with the Hot Spot Monitor (HSM); a non-conductive temperature monitoring device that identifies potential hot spots in critical equipment and alerts users to abnormalities before they lead to unplanned shutdowns.

To complement to the HSM, GraceSense has incorporated field-proven IIoT smart devices capable of monitoring asset health and alerting personnel to potential abnormalities through the web-based Maintenance Hub that provides real-time dashboard, analytics, alert capabilities and configuration. Among these predictive smart devices are the Vibration and Temperature Nodes and Panel-Mount Cloudgate/Nodes.

To support you in your IIoT effors, we provide a full service monitoring packages to help ensure that you get the most from what our GraceSense Predictive Maintenance System has to offer.

Lets get started!

Configure your cloudgates

Select from a variety of customizable transducer and power options, communication protocols and environmental ratings.

See Options.

maintenance hub setup

Our Customer Success team will help you setup your assets, folder structures, alarm thresholds, sampling rates and software integrations.

Learn more about our Maintenance Hub.

select a service package

Select from a variety of service packages that ensure that you are getting the full benefits of your Predictive Maintenance System.

See our Full Service Offerings.

Don't Worry, We are Here to help. Request a consultation here.

How it works

Need to learn more first? Check out our article "Why Vibration Analysis".

Download our free ebook

A proactive approach to electrical maintenance

-

How to strategize your maintenance program with maximum uptime through Predictive Maintenance solutions

-

Analyze the root causes of electrical failures and learn how to prevent them

-

Learn the features and benefits of continuous temperature remote monitoring versus periodic IR thermal inspections

-

How to enhance your maintenance program to improve overall personnel safety