Power of Continuous Thermal Monitoring: A Game Changer in Electrical Maintenance

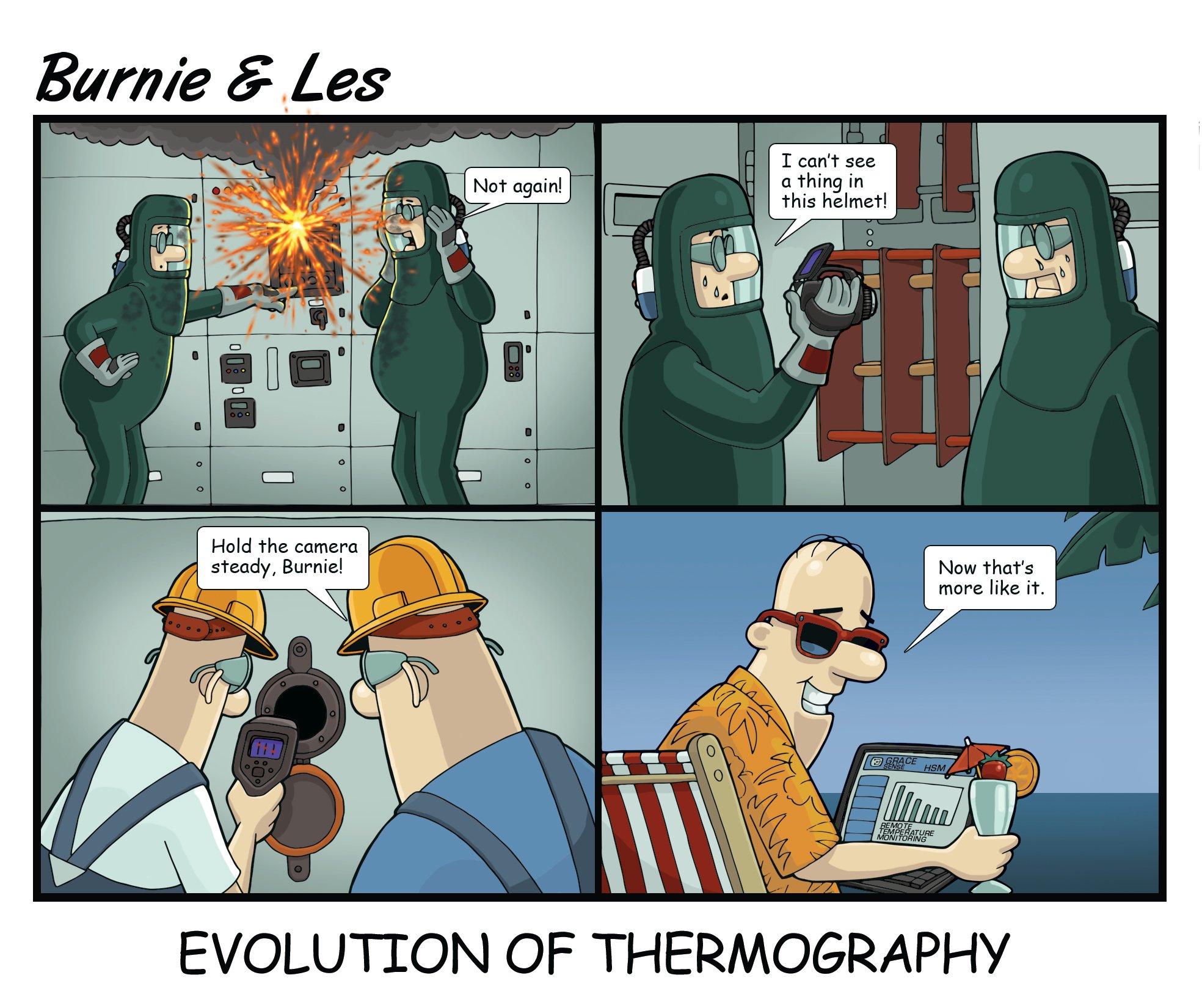

As industries evolve with technology, continuous thermal monitoring (CTM) has become critical in electrical maintenance strategies. Drawing from the discussions in our recent webinar on "Advancing Electrical Safety: NFPA 70B Compliance and Continuous Thermal Monitoring" and the insights provided by our CEO Drew Allen and Industry Strategy Director Shelly DeGrate, we shed light on the importance of CTM and its integration into modern safety standards like NFPA 70B.

1. Proactive Fault Detection

Continuous thermal monitoring provides real-time data that helps predict and prevent potential failures before they occur. As highlighted in our webinar, CTM systems like the GraceSense Hot Spot Monitor detect unusual temperature rises, often precursors to electrical failures. This proactive approach saves on costly repairs and significantly reduces downtime, making operations more efficient.

2. Compliance with Safety Standards

Adhering to regulatory standards such as NFPA 70B is not just about compliance—it's about ensuring the safety of personnel and operations. CTM systems help facilities maintain these standards by providing a consistent monitoring solution that can be integrated into safety protocols, as discussed in the webinar. This continuous oversight ensures that all components operate within safe thermal thresholds.

3. Enhanced Maintenance Scheduling

With CTM, maintenance teams can move from routine checks to condition-based maintenance strategies. This shift is crucial in optimizing resource allocation and extending the lifespan of critical equipment. By monitoring equipment conditions continuously, maintenance can be scheduled based on actual needs rather than predetermined intervals, leading to a more effective use of time and resources.

4. Reduction in Insurance Premiums

As noted in the webinar, implementing advanced monitoring systems like CTM can lead to lower insurance premiums. Insurers often provide better rates to facilities that proactively mitigate risks, such as installing systems that can prevent electrical fires and other hazards associated with equipment failures.

5. Integration with Modern Technologies

CTM systems integrate seamlessly with existing Industrial Internet of Things (IIoT) infrastructures, enhancing data analytics capabilities. This integration allows for detailed data analysis and better decision-making regarding equipment health. Facilities can leverage this integration to predict potential issues more accurately and tailor their maintenance strategies accordingly.

Elevate Your Maintenance Strategy with GraceSense

The GraceSense Hot Spot Monitor is at the forefront of CTM technology, transforming how facilities approach electrical safety and maintenance efficiency. This cutting-edge device not only monitors temperatures in real time but also dives deep into diagnostics, offering a clear window into the health of your electrical systems.

Applications Galore: Where Precision Meets Need

- Industrial Manufacturing: Prevents downtime by monitoring critical machinery and detecting overheating conditions before failures occur.

- Energy Sector: Ensures the reliability of transformers and switchgear by continuously tracking their thermal performance.

- Data Centers: Guards against overheating in servers and UPS systems, which are crucial for maintaining uptime and data integrity.

- Healthcare Facilities: Monitors medical imaging and diagnostic equipment to prevent unexpected malfunctions and ensure patient safety.

Robust Features that Redefine Monitoring

- Real-Time Temperature Monitoring: Continuously tracks temperature changes, catching anomalies that could signify potential failures.

- Detailed Diagnostics: Analyzes temperature data to provide insights into the specific nature and severity of detected issues.

- Seamless Integration: It easily integrates with existing maintenance systems and IoT platforms, enhancing the utility and accessibility of collected data.

Benefits: Why the Hot Spot Monitor is Essential

- Preventative Maintenance: Enables proactive maintenance decisions, reducing the need for reactive repairs and associated costs.

- Enhanced Safety: Minimizes the risk of electrical fires and other safety hazards by early detection of abnormal heating.

- Operational Continuity: Ensures that equipment runs within safe thermal thresholds, preserving the lifespan of critical infrastructure.

Notable Features at a Glance:

- Non-Intrusive Installation: This type of installation can be installed without disrupting existing operations, making it ideal for environments where unscheduled downtime is not an option.

- Flexible Alarm Thresholds: Customizable settings allow tailored monitoring based on specific equipment and environmental conditions.

- Data Logging and Trend Analysis: Stores temperature data for historical analysis, helping predict trends and plan maintenance schedules more effectively.

Integrating the GraceSense Hot Spot Monitor into your maintenance regimen enhances your facility's operational efficiency and bolsters its safety protocols. This tool is not just about monitoring; it's about empowering facilities to act before minor issues escalate into costly disasters.

Ready to take your preventive maintenance to the next level? The GraceSense Hot Spot Monitor is key to unlocking a more reliable, safe, and efficient operational future.

Elevating your maintenance strategy with CTM technology like the GraceSense Hot Spot Monitor isn’t just an operational decision—it’s a strategic masterstroke for safety, efficiency, and compliance.

Ready to transform your approach to electrical maintenance with CTM? Download our detailed GraceSense eBook, "A Proactive Approach to Electrical Maintenance," to tap into the power of proactive monitoring.