Preventing Switchgear Failures and the Role of Continuous Thermal Monitoring

Electrical switchgear is an essential component in power systems, tasked with controlling, protecting, and isolating electrical circuits and equipment. Despite its critical role, switchgear is susceptible to failures that can lead to severe disruptions.

Understanding these risks and employing effective maintenance strategies, such as continuous thermal monitoring (CTM), is crucial for maintaining system integrity and reliability. The GraceSense Hot Spot Monitor offers an advanced solution to these challenges.

What is Switchgear?

Switchgear is a critical component of electrical systems and comprises various devices such as circuit breakers, fuses, disconnect switches, and relays, all securely housed within a sturdy metal enclosure.

This equipment plays a pivotal role in power transmission and distribution networks by managing, protecting, and isolating electrical power with high efficiency and reliability. Here's a closer look at the core functions of switchgear:

- Control

- Switchgear controls the flow of electrical power throughout an installation.

- It includes manual or automated switches and circuit breakers that can initiate or interrupt the flow of electricity through electrical circuits.

- This function is crucial for managing power distribution efficiently and responding quickly to changing network conditions or operational demands.

- Protection

- One of the primary roles of switchgear is to protect the electrical network from damage caused by overloads or short circuits.

- Switchgear can trigger protective measures that prevent excessive current from damaging equipment or causing fire hazards by monitoring electrical currents and detecting fault conditions.

- These measures include actuating circuit breakers that disconnect the faulty section of the network to prevent further damage.

- Isolation

- Switchgear provides essential isolation of electrical circuits, allowing for safe maintenance, testing, and fault rectification.

- It enables parts of the electrical system to be de-energized while others continue to operate, thus facilitating repairs or upgrades without shutting down the entire system.

- This feature is critical for maintaining system stability and ensuring the safety of maintenance personnel exposed to high voltages during work.

Switchgear effectively manages, protects, and isolates electrical power, ensuring the stability and safety of electrical distribution networks. It is essential for preventing disruptions and maintaining a continuous power supply in various settings, from industrial facilities to commercial buildings.

Understanding these functions helps underscore the importance of switchgear in modern electrical infrastructure and highlights the need for reliable equipment and regular maintenance to safeguard its operation.

Top 5 Causes of Switchgear Failures

Switchgear reliability is critical for ensuring electrical power's continuous and safe distribution. The dependability of these systems is influenced by various factors, each capable of impacting performance and longevity:

- Overheating

- Switchgear components can overheat due to overloading or poor electrical connections, which increases resistance and generates excessive heat.

- This condition can damage insulation and lead to the failure of critical components such as circuit breakers and relays.

- Persistent overheating can also cause premature system aging, potentially leading to unexpected downtimes and hazardous situations.

- Mechanical Wear and Tear

- Regular use of switchgear inevitably leads to mechanical wear and tear.

- Components such as switches, circuit breakers, and relays are subjected to physical stresses during operation, which can degrade their structural integrity over time.

- This deterioration can affect the functionality of switchgear, reducing its ability to perform essential tasks like breaking circuits and isolating electrical loads.

- Environmental Conditions

- The environment in which switchgear operates significantly affects its reliability.

- Harsh conditions involving dirt, dust, moisture, and corrosive gases can lead to the corrosion of metal parts and the contamination of insulating materials.

- These factors can accelerate the wear and degradation of switchgear components, making them more susceptible to malfunction.

- Inadequate Maintenance

- Proper maintenance is crucial for the longevity and reliability of switchgear.

- Neglecting routine maintenance checks, such as tightening loose connections, cleaning components, and checking for signs of wear and tear, can lead to minor, manageable issues escalating into serious problems.

- Inadequate maintenance often results in failures that could have been easily prevented with regular inspections and servicing.

- Design and Manufacturing Defects

- The switchgear's initial design and manufacturing quality are pivotal in its long-term performance.

- Design flaws or defects in manufacturing can introduce weaknesses that may not become apparent until the equipment is subjected to operational stresses.

- Such defects might include inadequate spacing for heat dissipation, improper material selection, or substandard assembly practices, which can compromise the switchgear's efficiency and safety.

Benefits of Implementing Continuous Thermal Monitoring

Adopting CTM with advanced solutions like the GraceSense Hot Spot Monitor significantly elevates maintenance strategies, offering a multitude of operational benefits:

- Enhanced Safety

- The Hot Spot Monitor enables maintenance personnel to remotely observe electrical system conditions, reducing the need to interact with potentially dangerous equipment physically.

- This capability drastically lowers the risk of electrical failures and minimizes personnel exposure to hazardous conditions, enhancing workplace safety.

- Reduced Downtime

- The Hot Spot Monitor continuously monitors temperature data, allowing for the early detection of anomalies that could lead to equipment failure.

- This proactive approach enables maintenance teams to schedule interventions at optimal times before failures disrupt operations, maintaining continuous system availability and operational efficiency.

- Cost Savings

- Anticipating and addressing potential issues before they escalate into significant failures reduces the likelihood of costly emergency repairs and the need for premature equipment replacement.

- Over time, this proactive maintenance strategy can lead to substantial cost savings, optimizing electrical systems' overall lifecycle costs.

- Compliance and Standards

- Employing the Hot Spot Monitor helps organizations comply with industry standards and regulatory requirements, such as NFPA 70B, which advocates for regular maintenance to ensure electrical systems are kept in prime condition.

- Continuous thermal monitoring is recognized as a critical component of a comprehensive electrical maintenance program, helping facilities more effectively meet these standards.

- Streamlined Maintenance Operations

- Integrating CTM systems like the Hot Spot Monitor simplifies the maintenance process by directly providing maintenance teams with clear, actionable data.

- This approach improves the efficiency of maintenance scheduling and resource allocation, reducing unnecessary inspections and focusing efforts where they are most needed.

- Long-Term Asset Health

- Continuous monitoring extends the life of electrical components by preventing damage that can result from overheating and other related issues.

- By maintaining equipment within operational temperature ranges, the integrity and performance of electrical assets are preserved over the long term, ensuring their reliability and durability.

- Improved Data Analysis and Reporting

- The Hot Spot Monitor collects comprehensive data over time, providing valuable insights into electrical systems' health and performance trends.

- This data can be analyzed to refine maintenance strategies, develop better predictive maintenance protocols, and enhance reporting accuracy for internal audits and regulatory compliance.

A Game-Changer in Electrical Maintenance

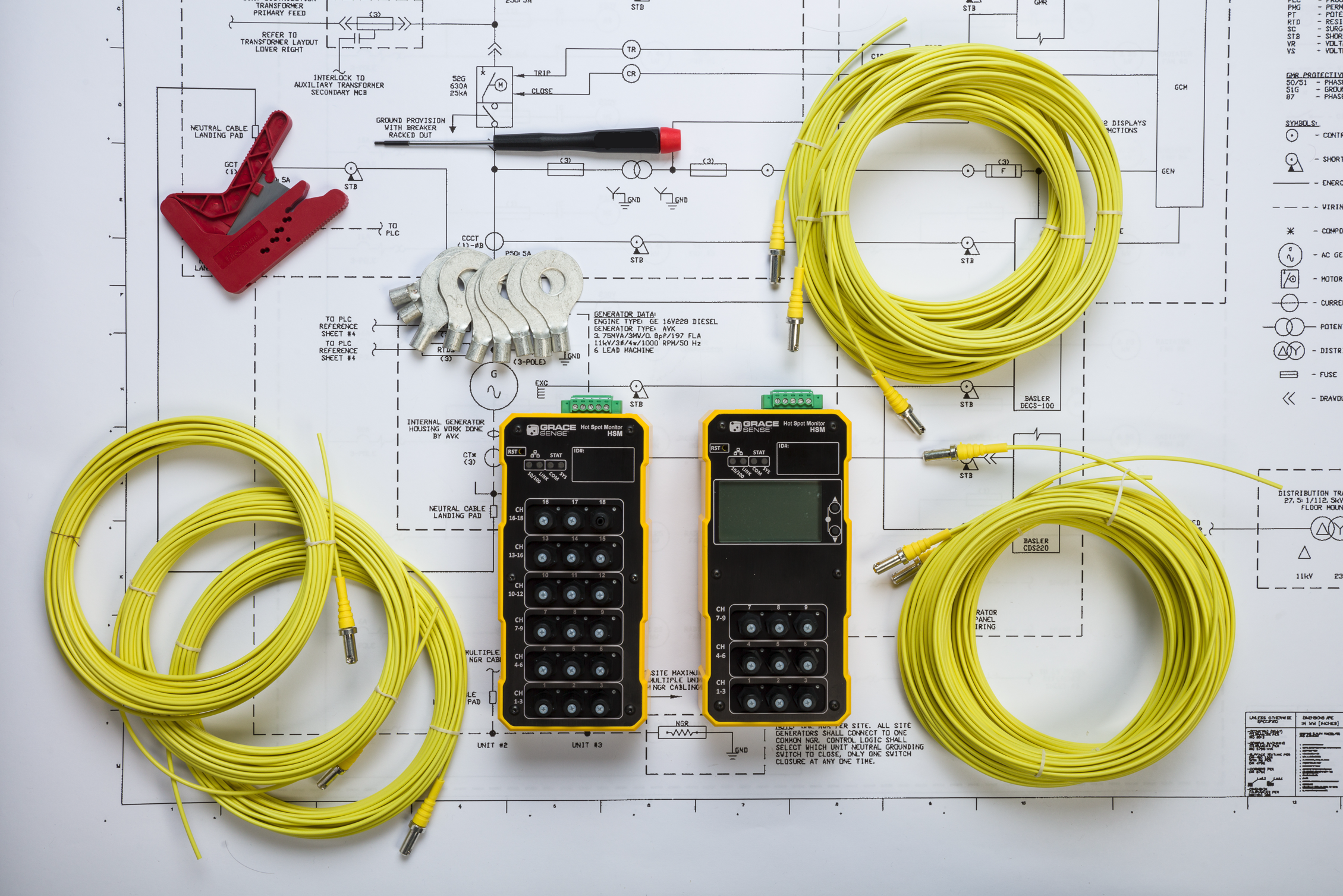

The GraceSense Hot Spot Monitor is a pivotal tool engineered explicitly for CTM in switchgear systems. It uses state-of-the-art sensors to continually scan for abnormal heating patterns, a key indicator of potential electrical faults.

By providing real-time, actionable insights, this system is essential for preventing failures that could lead to costly downtime and safety hazards. Here are some of the innovative features of the Hot Spot Monitor:

- Real-Time Monitoring

- The Hot Spot Monitor has high-precision sensors tracking temperature variations within the switchgear.

- This capability immediately detects hot spots that could indicate impending failures, even in areas typically tricky to monitor manually.

- Preventive Analytics

- Beyond simple temperature monitoring, the Hot Spot Monitor employs sophisticated analytics to process temperature data.

- This system interprets the thermal data to forecast potential failure points, allowing maintenance teams to switch from a reactive to a proactive maintenance strategy.

- By anticipating problems before they occur, plants can avoid unplanned outages and extend the lifespan of their electrical equipment.

- Easy Integration

- Designed for flexibility, the Hot Spot Monitor can be integrated into any existing switchgear setup without requiring extensive modifications or system downtime.

- This ease of integration ensures smooth implementation and does not interfere with ongoing operations.

- It is an ideal solution for facilities upgrading their maintenance practices without significant initial disruption.

- Customizable Alarm Thresholds

- Users can set specific temperature thresholds that trigger alarms when exceeded, ensuring immediate attention to critical areas and facilitating quick response to prevent damage.

- Comprehensive Connectivity

- The device supports multiple communication protocols, including EtherNet/IP, Modbus TCP, and wireless options, making it versatile for integrating various industrial control systems.

- This connectivity allows for easy data aggregation and analysis across platforms.

- Durable and Reliable

- The Hot Spot Monitor is robust and reliable, built to withstand the harsh environments typically found in industrial settings.

- Its design ensures it operates effectively under various environmental conditions, from high humidity to dusty conditions, ensuring consistent performance without frequent maintenance.

Strategic Maintenance with GraceSense

Integrating the GraceSense Hot Spot Monitor into your electrical maintenance routines ensures a higher level of reliability and operational efficiency. It's not just about preventing failures; it's about enhancing the performance and longevity of your electrical investments.

Switchgear is indispensable in managing electrical power distribution and ensuring safety in various industrial applications. With the Hot Spot Monitor, you'll have a robust solution that leverages continuous thermal monitoring to mitigate the risks associated with switchgear failures.

Request a product demonstration to maintain peak operational efficiency and safety.

Elevating your maintenance strategy with CTM technology like the GraceSense Hot Spot Monitor isn’t just an operational decision—it’s a strategic masterstroke for safety, efficiency, and compliance. Ready to transform your approach to electrical maintenance with CTM?

Download our detailed GraceSense eBook, "A Proactive Approach to Electrical Maintenance," to learn more about the power of proactive monitoring.