A Comprehensive Guide with a Bonus Step for Enhanced Safety and Efficiency

Protecting personnel from electrical hazards and operational risks during programmable logic controller (PLC) programming is critical to prevent injuries and ensure uninterrupted industrial operations. By adhering to a structured safety protocol, organizations can protect their workforce while maintaining high productivity.

This guide outlines a three-step process to mitigate safety risks during PLC programming and introduces a bonus step that highlights the benefits of integrating GracePort panel interface connectors for improved safety and efficiency.

Understanding PLC Installations and the Associated Safety Risks

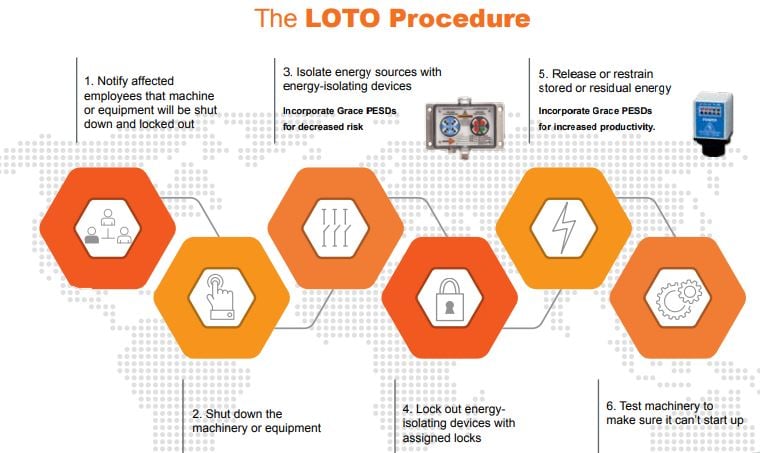

Installed in various settings to manage and control machinery and processes, PLCs are integral components of industrial automation systems. Their installation sites and the inherent dangers associated with accessing them underscore the importance of stringent safety measures, including protocols like Lockout/Tagout (LOTO) and the integration of safety-enhancing solutions like panel interface connectors.

PLCs are frequently housed within Industrial Control Panels (ICPs), which serve as centralized units containing the electrical controls for machinery and industrial processes. These panels are typically located in environments that are:

- Electrically Hazardous: ICPs are connected to high-voltage power supplies, posing risks of electrical shock or arc flash incidents to personnel accessing the PLC for maintenance or programming.

- Environmentally Challenging: Many ICPs are situated in areas exposed to extreme temperatures, dust, moisture, or corrosive substances, requiring careful consideration to ensure safety and equipment integrity.

- Mechanically Complex: The dense arrangement of components within ICPs, including wiring, switches, and circuit breakers, increases the risk of accidental contact with live parts or causing short circuits during access.

Step 1: Preparation - Laying the Foundation for Safety

- Conduct a Risk Assessment

- Before any programming begins, conduct a thorough risk assessment of the PLC system and its environment.

- Risk assessment should identify potential hazards related to electrical risks, moving machinery, and any other environmental factors.

- Establish Safe Work Practices:

- Based on the risk assessment, develop and document safe work practices.

- Define procedures for LOTO to prevent accidental startup, specifying personal protective equipment (PPE) requirements, and outlining steps to safely initiate changes in the programming.

- Train Personnel

- Ensure that all individuals involved in the PLC programming process are adequately trained in safe work practices, emergency procedures, and the specific steps of the programming task at hand.

- Training should also cover the interpretation of PLC diagnostics and alarms that may indicate safety-related issues.

Step 2: Execution - Implementing Safety Measures

- Implement LOTO Procedures

- Before starting the programming, apply LOTO procedures to isolate the PLC and any connected machinery from energy sources.

- This step is vital to protect personnel from electrical hazards and unexpected equipment activation.

- Use Appropriate PPE

- Depending on the risk assessment, personnel should wear the necessary PPE, which may include electrical gloves, safety glasses, and other protective gear to mitigate the risk of injury.

- Follow Programming Protocols

- Carefully follow the established programming protocols, which should include steps for safely applying changes to the PLC.

- Where possible, utilize simulation tools or test environments to verify changes before they are applied to the live system.

Step 3: Verification - Ensuring Safety and Accuracy

- Test and Verify Changes:

- Once the programming changes have been applied, conduct a controlled test to verify that the changes have been implemented correctly and that they function as intended.

- Testing should be done under safe conditions, ideally with machinery in manual mode or with adequate safeguards in place.

- Conduct a System Safety Check

- Before returning the system to normal operation, perform a comprehensive safety check to ensure that all guards, safety devices, and controls are in place and functioning correctly.

- Verify that the PLC programming does not introduce new hazards.

- Review and Document

- After the programming and verification are complete, review the process to identify any issues or areas for improvement.

- Document the changes made, including details of the programming adjustments and any incidents or near-misses that occurred.

- Documentation will be valuable for future safety assessments and continuous improvement efforts. Keep up to date with the latest OSHA requirements here.

Bonus Step: Integrating Panel Interface Connectors

Integrating GracePort panel interface connectors transforms the PLC programming safety process by adding a layer of convenience and enhanced safety, without compromising on productivity. Here’s how:

- Enhanced Safety

- GracePort connectors allow for PLC programming and diagnostics to be performed externally, significantly reducing the need to expose personnel to electrical hazards inside the control panel.

- External access minimizes interactions with live electrical components, aligning with the hierarchy of control for risk mitigation.

- Convenient Access

- With GracePort connectors, technicians can easily connect laptops or programming devices directly to the PLC through a safe, external interface.

- Convenient access eliminates the cumbersome process of opening the panel for routine diagnostics or updates, streamlining maintenance tasks.

- Streamlined Productivity

- By facilitating quicker and safer access to PLCs for programming and monitoring, GracePort connectors reduce downtime.

- Technicians can perform necessary adjustments and diagnostics without the extensive prep work traditionally required for panel access, keeping production lines moving more smoothly.

Incorporating GracePorts into the PLC programming process represents a significant step forward in industrial safety and efficiency. By combining traditional safety protocols with the innovative features of GracePort connectors, organizations can achieve a higher standard of operational excellence and worker protection.

Take the first step towards operational excellence and enhanced worker protection by requesting your customizable GracePort sample today. Experience the innovative features that set GracePort connectors apart in industrial safety and efficiency.