In the realm of industrial automation, Industrial Control Panels (ICPs) and Programmable Logic Controllers (PLCs) are fundamental components driving the operational efficiency of a vast array of systems. From manufacturing plants to utility control rooms, these components are critical for various automated processes, yet their maintenance and programming can pose significant safety risks.

Understanding ICPs and PLCs

ICPs serve as the nerve centers of industrial automation, housing crucial electrical control hardware, including PLCs. PLCs are the brains of the operation, programmed to automate specific tasks in the production process. They are frequently accessed for various reasons, from routine maintenance to critical updates in programming, often necessitating direct interaction with the control panel.

The Safety Risks in PLC Access

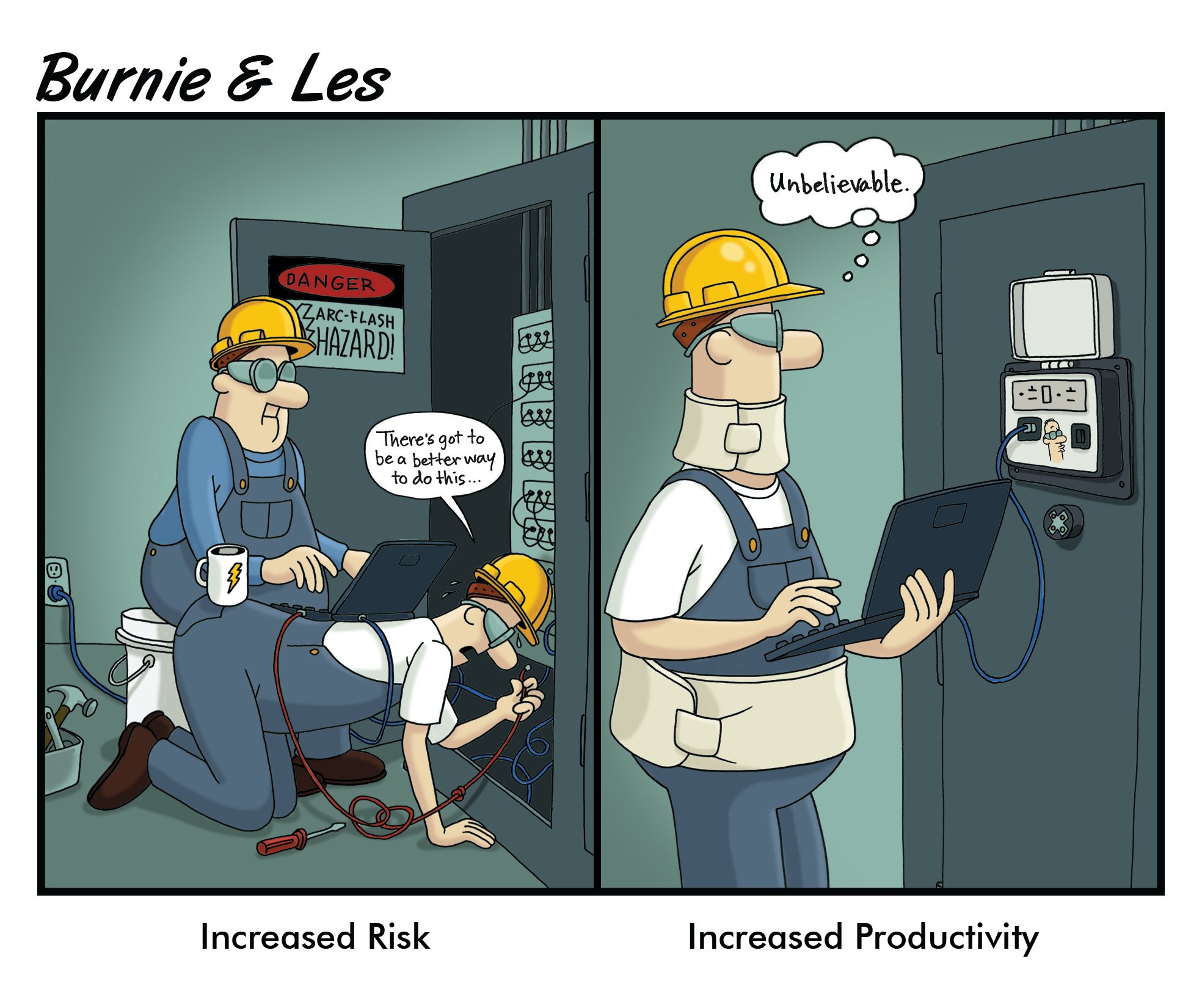

Accessing PLCs traditionally involves opening the ICP doors, which can expose technicians to potential electrical hazards. According to the Occupational Safety and Health Administration (OSHA), electrical accidents rank among the most common causes of workplace injuries in industrial settings. The exposure to live circuits while working inside an open panel significantly increases the risk of electrical shocks, arc flash incidents, and other related injuries.

GracePort: A Safety-Centric Solution

Enter GracePort, a suite of panel interface connectors designed to mitigate these risks by allowing access to PLCs without opening the ICP doors. This innovative solution offers a direct, yet secure, bridge between the internal PLC and the external environment, effectively minimizing the need for direct interaction with live electrical components.

How GracePort Improves Safety and Efficiency

-

Reduced Exposure to Electrical Hazards: By providing PLC access through closed doors, GracePort significantly lowers the risk of electrical accidents. This not only aligns with OSHA’s safety regulations but also adheres to the National Fire Protection Association’s NFPA 70E standards, which emphasize the importance of electrical safety in the workplace.

-

Enhanced Operational Efficiency: Frequent access to PLCs is a given in most industrial scenarios. GracePort streamlines this process by simplifying access. This ease of use translates to reduced downtime and a more efficient workflow, as technicians can quickly connect to the PLC for programming or troubleshooting without the cumbersome process of opening the panel and donning personal protective equipment (PPE).

-

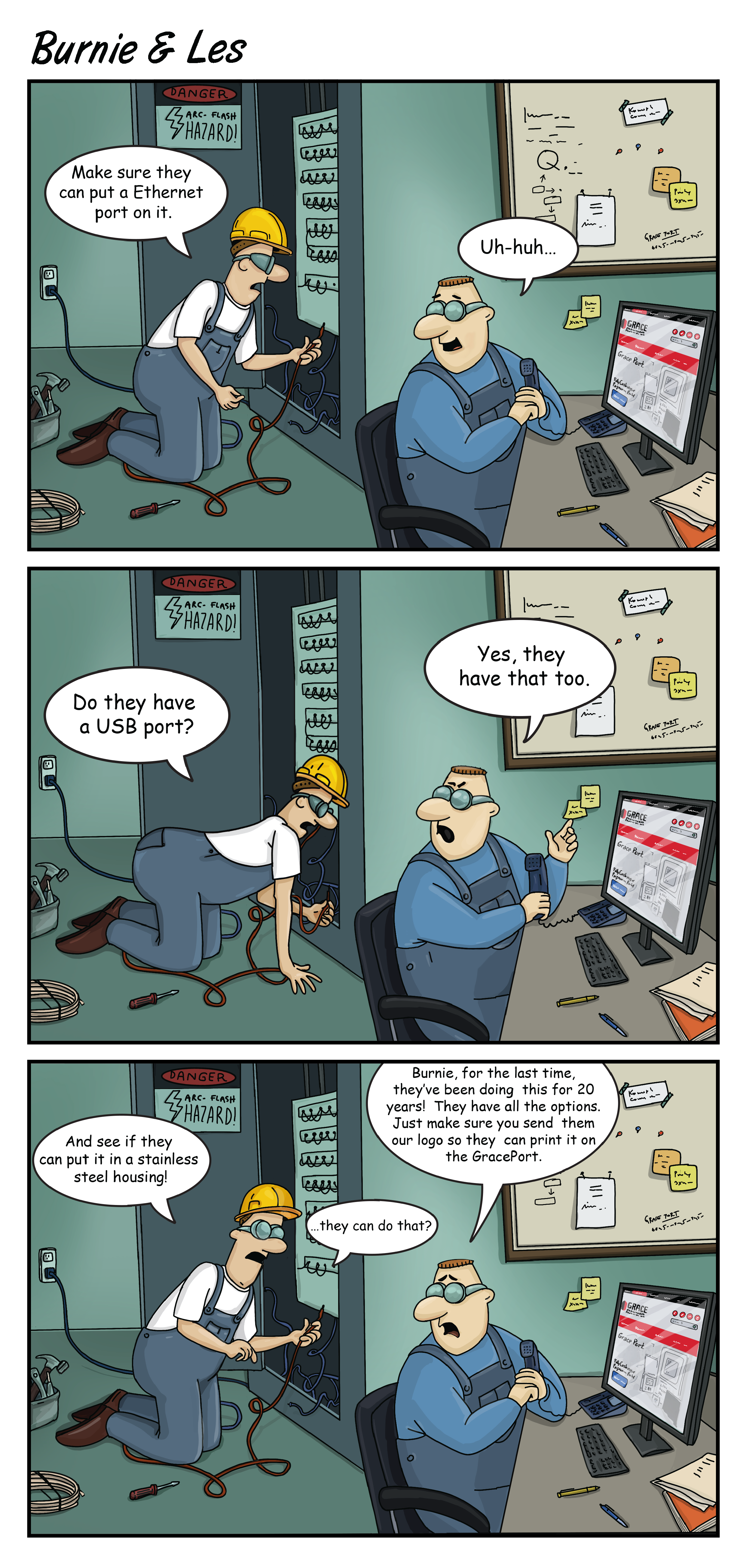

Customizable Solutions: GracePort’s true strength lies in its adaptability. With an array of customizable solutions, including various components and power options, GracePort can be tailored to fit specific industrial needs. This flexibility ensures that regardless of the industry or the specific type of PLC used, there’s a GracePort solution that can enhance both safety and efficiency.

Practical Applications and Industry Impact

In industries where ICPs and PLCs are frequently accessed – such as manufacturing, energy, and water treatment – the introduction of GracePort connectors has revolutionized maintenance and programming tasks. By significantly reducing the risks associated with these tasks, GracePort has not only protected workers but also improved the overall productivity of operations.

The integration of GracePort in industrial settings is more than just an advancement in safety and efficiency; it’s a transformative step towards safer, smarter, and more productive operations. By providing safe, easy, and customizable access to PLCs through closed ICP doors, GracePort stands as a beacon of innovative engineering, adeptly addressing critical safety concerns while boosting operational productivity.

Are you ready to delve deeper into the world of safer and more efficient industrial operations? Download our comprehensive GracePort eBook today. Inside, you'll find detailed insights, real-world applications, and a closer look at how GracePort solutions are making a tangible difference across various industries. Equip yourself today with the knowledge to make your workplace safer and more efficient.