The Power of IIoT Technology with Safety by Design

The Power of IIoT Technology with Safety by Design

In industrial settings, safety is paramount, and the prevention of workplace injuries is a top priority. One significant factor contributing to the risk of injuries is unplanned downtime, which often occurs during reactive maintenance. However, with the advent of IIoT predictive maintenance technology, a paradigm shift is underway.

By proactively addressing maintenance needs and minimizing unplanned downtime, IIoT predictive maintenance systems are revolutionizing safety practices in industrial environments. In this blog, we will explore how safety is ingrained in the design of predictive maintenance, its role in preventing injuries, and how the GraceSense predictive maintenance system can be the key to unlocking a safer work environment.

.jpg?width=2296&height=1208&name=IIoT%20Social%20214052%20(1).jpg)

Safety by Design: The Core Principle of Predictive Maintenance

Predictive maintenance is not just about optimizing equipment performance and extending asset life; it is also about embedding safety into every facet of maintenance operations. Here's how predictive maintenance, enabled by IIoT technology, enhances safety by design:

- Minimizing Reactive Maintenance: Reactive maintenance, often carried out during unexpected equipment failures, poses significant safety risks. Predictive maintenance leverages real-time data and advanced analytics to identify potential equipment issues before they escalate. By reducing or eliminating reactive maintenance, the likelihood of injuries occurring due to sudden equipment failures is greatly diminished.

- Proactive Planning and Risk Mitigation: Predictive maintenance empowers maintenance teams to plan their activities strategically. By accurately forecasting equipment health and maintenance requirements, teams can schedule maintenance tasks during planned downtime, ensuring a controlled and safe working environment. This proactive approach minimizes the risk of working on malfunctioning equipment and reduces the likelihood of accidents.

- Remote Monitoring and Condition-Based Alerts: IIoT predictive maintenance systems, such as GraceSense, offer remote monitoring capabilities, enabling maintenance teams to monitor equipment health without direct physical interaction. Condition-based alerts provide timely notifications about critical issues, allowing teams to take preventive actions promptly. By minimizing the need for manual inspections and troubleshooting, the risk of injuries associated with hands-on maintenance tasks is significantly reduced.

- Data-Driven Safety Insights: Predictive maintenance systems generate a wealth of data that can be analyzed to identify safety trends and patterns. By analyzing historical maintenance records and equipment performance data, safety professionals can gain valuable insights to proactively address potential safety hazards. This data-driven approach to safety empowers organizations to continuously improve their safety protocols and reduce the risk of injuries.

How GraceSense is Empowering Safety-Centric Predictive Maintenance

GraceSense predictive maintenance system, developed by Grace Technologies, is a comprehensive solution designed to maximize safety in industrial environments. Here's how GraceSense contributes to safety by design:

- Real-Time Equipment Monitoring: GraceSense utilizes IIoT technology to continuously monitor equipment health in real-time. By collecting data from sensors and employing advanced analytics, GraceSense provides early warnings about potential equipment failures, allowing maintenance teams to take proactive measures to ensure safety.

- Remote Access and Condition Monitoring: With GraceSense, maintenance teams can remotely access equipment data and perform condition monitoring from any location. By minimizing physical contact with equipment, the risk of injuries associated with on-site inspections is reduced. Real-time condition monitoring also enables quick identification of any safety-related anomalies or deviations.

- Intelligent Alarming and Actionable Insights: GraceSense's intelligent alarming system sends instant notifications to maintenance personnel when equipment health parameters exceed predefined thresholds. These actionable insights enable timely responses and preventive measures to be taken, reducing the likelihood of accidents caused by equipment malfunctions.

- Seamless Integration and Scalability: GraceSense integrates seamlessly with existing infrastructure, making it compatible with various equipment types and applications. Whether it's rotating equipment or other critical assets, GraceSense offers a scalable solution to enhance safety across diverse industrial environments.

Predictive maintenance powered by IIoT technology is transforming safety practices in industrial settings. By proactively addressing maintenance needs, minimizing unplanned downtime, and enabling data-driven decision-making, predictive maintenance systems like GraceSense are placing safety at the forefront of maintenance operations. With real-time equipment monitoring, remote access capabilities, intelligent alarming, and seamless integration, GraceSense empowers organizations to create a safety-centric maintenance culture.

By adopting predictive maintenance practices and leveraging the GraceSense predictive maintenance system, businesses can experience a multitude of benefits, including:

- Enhanced Safety: By reducing or eliminating unplanned downtime and proactively addressing maintenance needs, the risk of injuries due to sudden equipment failures is significantly reduced

- Increased Efficiency: Predictive maintenance enables maintenance teams to plan strategically, optimize resource allocation, and minimize equipment downtime. This translates to improved operational efficiency and productivity

- Cost Savings: By avoiding costly repairs, preventing equipment failures, and optimizing maintenance schedules, predictive maintenance helps organizations save on maintenance expenses and extend the lifespan of their assets.

- Data-Driven Insights: The data collected by predictive maintenance systems offers valuable insights into equipment health, performance trends, and potential safety hazards. This knowledge allows organizations to continuously improve safety protocols and make informed decisions.

In the pursuit of a safer work environment and efficient maintenance practices, it is essential for businesses to embrace the transformative potential of IIoT predictive maintenance. Discover how GraceSense can revolutionize your maintenance operations and unlock the benefits of safety by design. Take the first step towards safer, more reliable operations by exploring the power of GraceSense predictive maintenance today.

Learn more about GraceSense and how it can elevate your maintenance practices to new heights. Contact us to schedule a demo and witness firsthand the transformative impact of predictive maintenance on safety, efficiency, and cost savings.

Grace Technologies is dedicated to helping you achieve maintenance excellence and create a safer working environment through cutting-edge predictive maintenance solutions. Together, let's harness the power of IIoT technology to revolutionize your maintenance practices and enhance safety at every level.

Join our webinar to discover the transformative power of the Industrial Internet of Things (IIoT) in revolutionizing maintenance practices. Explore how IIoT technologies can enable predictive maintenance strategies, enhance equipment uptime, and optimize maintenance efficiency. Gain insights into real-time asset monitoring, advanced data analytics, and the seamless integration of IIoT with existing maintenance programs. Unleash the potential of IIoT for predictive maintenance excellence and elevate your maintenance practices to new heights.

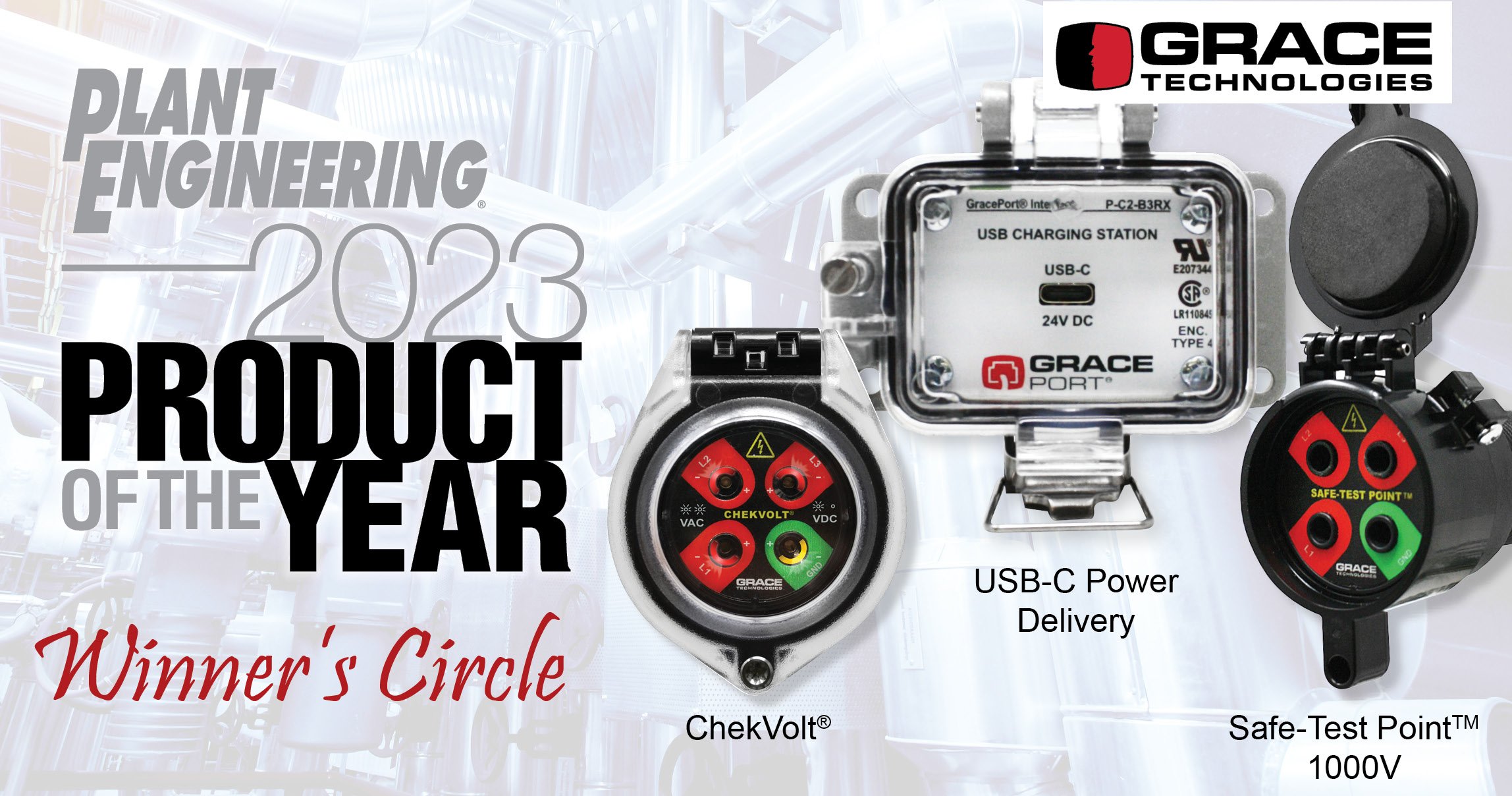

We are thrilled to announce that Grace Technologies has won multiple Plant Engineering Magazine's 2023 Product of the Year awards! ChekVolt® - Winner in Safety & Security, GracePort® USB-C Power Delivery - Winner in Power, & Safe-Test Point™ 1000V - Winner in Safety & Security.

Thank you to all our customers and supporters who voted! Request your ChekVolt product sample now and experience award-winning safety.