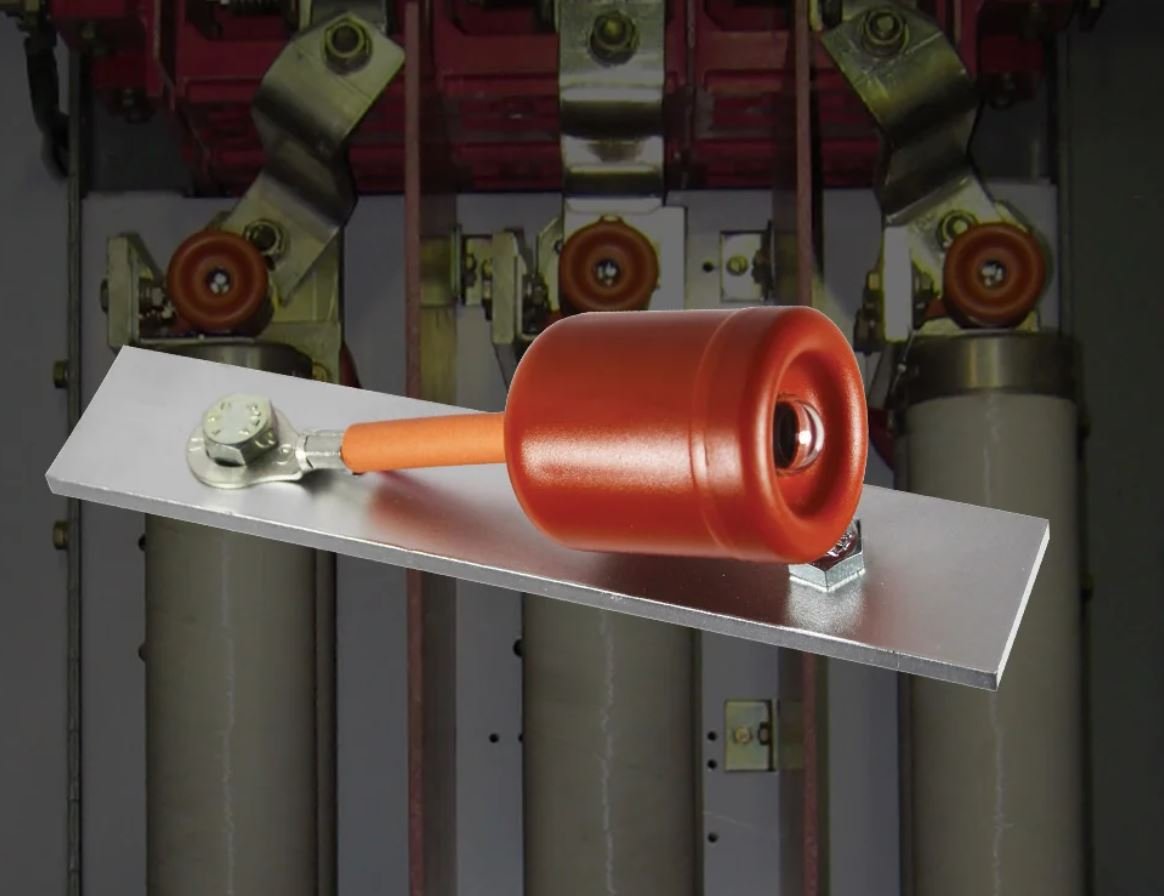

Our Permanent Electrical Safety Devices (PESDs) include an indicator for medium voltage application with the medium voltage indicator (R-1V). This PESD is installed differently than the previously mentioned indicators as it mounts directly onto a medium voltage bus to alert personnel to voltage presence with flashing LEDs. The medium voltage indicator is designed to provide sufficient illumination to be easily seen through a viewing window mounted on a medium voltage starter, transformer, switchgear, or other power distribution equipment. The R-1V indicator is built for long life and reliability with solid-state LEDs, is coated with flame-rated material, and uses capacitively-coupled resistivity to provide high surge immunity.

How does it work?

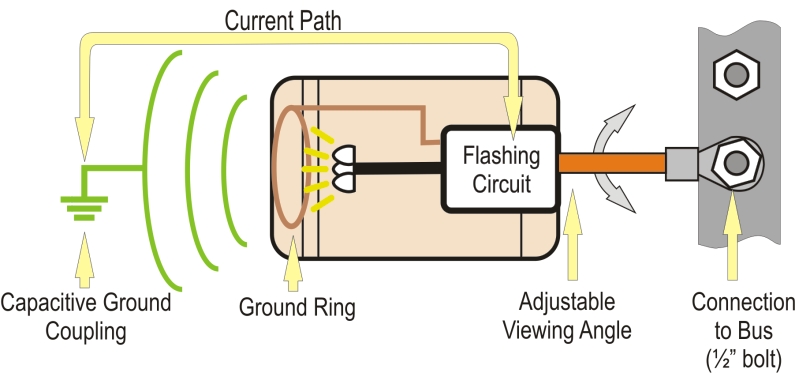

A medium voltage indicator is a single-phase device mounted onto each phase of a power bus. Energy from the bus flows through the indicator circuit through a capacitive ground connection. This means when higher voltages exist the air becomes slightly conductive allowing current to flow 'through the air,' which completes the flashing LED circuit. As the voltage increases, more current flows thereby increasing the flash rate. The enclosure size and the distance between the adjoining phases will also affect the flash rate.

Designed for Electrical Safety: No 'False-Negative'

When an electrician starts working on an energized conductor that just tested as 'dead' but is actually live, a dangerous situation called a 'false negative' indication is created. This means the voltage detector (falsely) indicated that there was no voltage (negative). The following are examples of how the design of a medium voltage indicator minimizes the opportunity for a 'false-negative' to occur:

- Self-powered circuitry: A voltage indicator connected to a given voltage source has its circuitry powered from the same source (self-powered by line voltage). Circuit designs relying upon another power supply or battery energizing its circuitry increases the number of components and connections between the 'line voltage' and the 'indicator'. Simply put, more stuff means less reliability. Furthermore, failure of the power supply creates a 'false-negative' meaning that voltage exists without indication.

- No fuses: A circuit design of a voltage indicator should not require fusing in order to protect its internal circuitry. Fuses add more connections and components reducing the overall reliability of the voltage indicator. In this case, a blown fuse creates a 'false-negative' voltage indication.

- Maintenance Free: A medium voltage indicator needs to have a long maintenance-free life (7+ years) because maintenance departments have other priorities than maintaining medium voltage indicators. A robust, long-life design means fewer device failures. This is important because a device failure is another example of a 'false negative' voltage indication.

- No 'hard-wired' Ground Connection: A short circuit to ground is a common failure mode with medium voltage equipment. A voltage indicator that provides a hard-wired path to ground introduces a high-risk failure point. A medium voltage indicator without a hard-wired ground connection eliminates this potential point of failure. This feature also provides built-in surge immunity.

Increase Safety & Productivity for Mechanical LOTO

Workers performing mechanical Lockout/Tagout (LOTO) procedures must isolate electrical energy. A voltage detector provides a means to check voltage inside a medium voltage enclosure. Without a voltage detector, a mechanic performing mechanical LOTO would be required to work in tandem with an electrician using a voltmeter to physically verify voltage inside an electrical panel. In this case, the electrician is exposed to voltage. With voltage detectors, the mechanic alone can verify zero electrical energy through a viewing window without any exposure to voltage.

Most agree that any low-cost device which simplifies maintenance and increases safety contributes to the high calling of electrical safety. The specific design and applications of medium voltage indicators increase employee productivity and enhance compliance to NFPA 70E.

Applications

Since medium voltage indicators mount inside enclosures, a viewing window will allow workers to see the flashing LEDs through the panel door without voltage exposure. Applications include:

- Motor Starters

- Metal Clad Switchgear

- Open Bus Work

- Medium Voltage Drives

- Isolation Switches

- Substation Switches

- Transfer Switches

- High-Resistance Ground Switches

For more information, please contact Sales@GraceTechnologies.com

Learn more about the benefits of Permanent Electrical Safety Devices for mechanical and electrical LOTO and enhance your compliance with electrical safety standards with safety-by-design. Download the FREE eBook today!