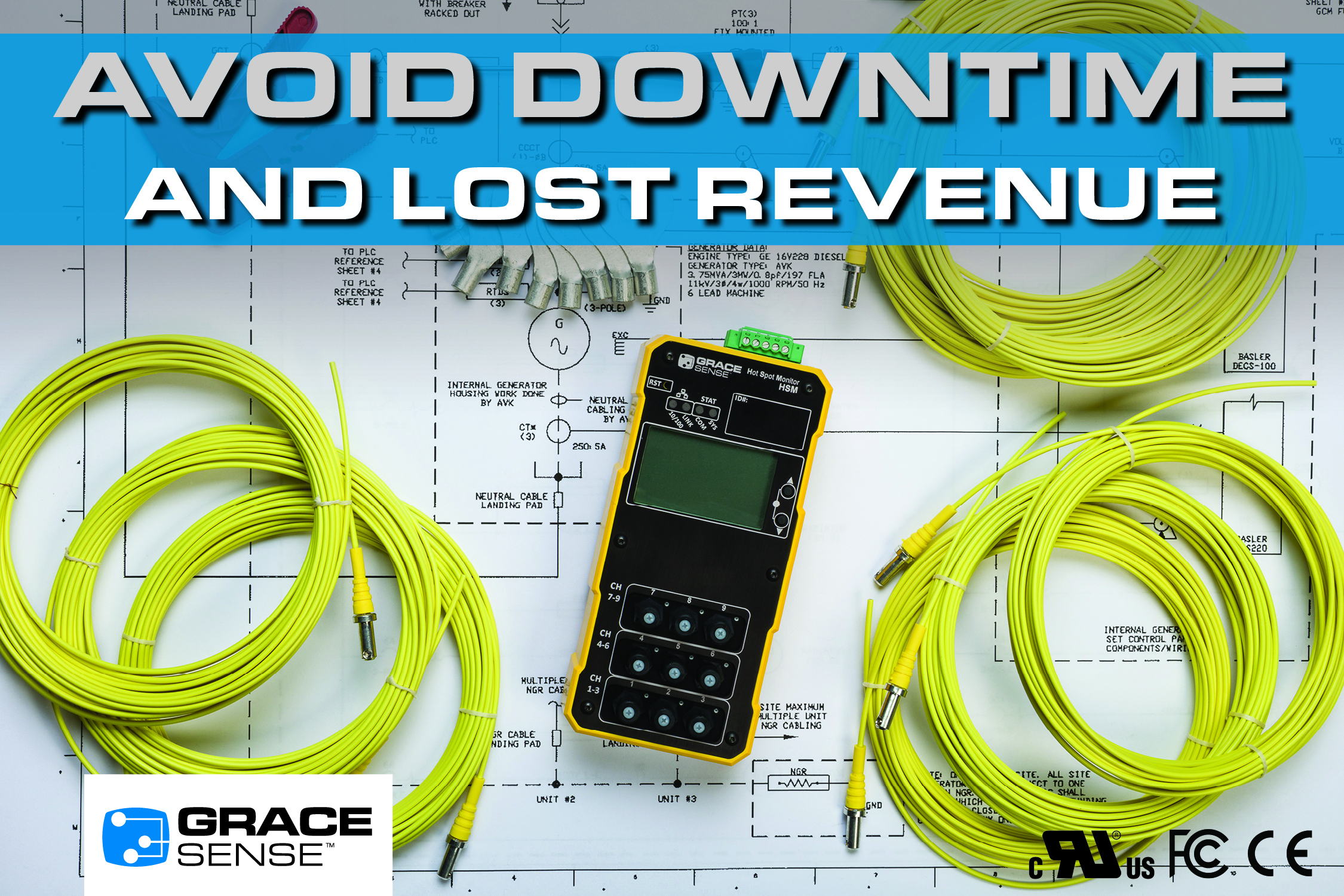

At Grace Technologies, our mission is to make maintenance safer, smarter, and more productive. An important factor in determining the reliability and uptime of an electrical system is the condition and the availability of the power distribution equipment such as low, medium, and high voltage switchgear (up to 80KV), transformers, and circuit breakers. In these types of equipment, loose connections commonly occur due to vibration, fault conditions, and thermal expansions. If unnoticed, they can cause failures and shutdowns, loss of productivity, and ultimately, loss of revenue.

Installation of a Hot Spot Monitor is simple and serves as a suitable and superior alternative to periodic thermography inspections. The Hot Spot Monitor identifies potential hot spots to enable users to predict the failures in electrical equipment. The device utilizes a non-conductive polymer optical fiber cabling system that monitors temperatures and alarms maintenance personnel when the temperatures rises or drops below the preset thresholds, indicating an imminent potential failure. Connections are secured through a ring style lug at the end of each of the provided nine to eighteen connection points, depending on the model.

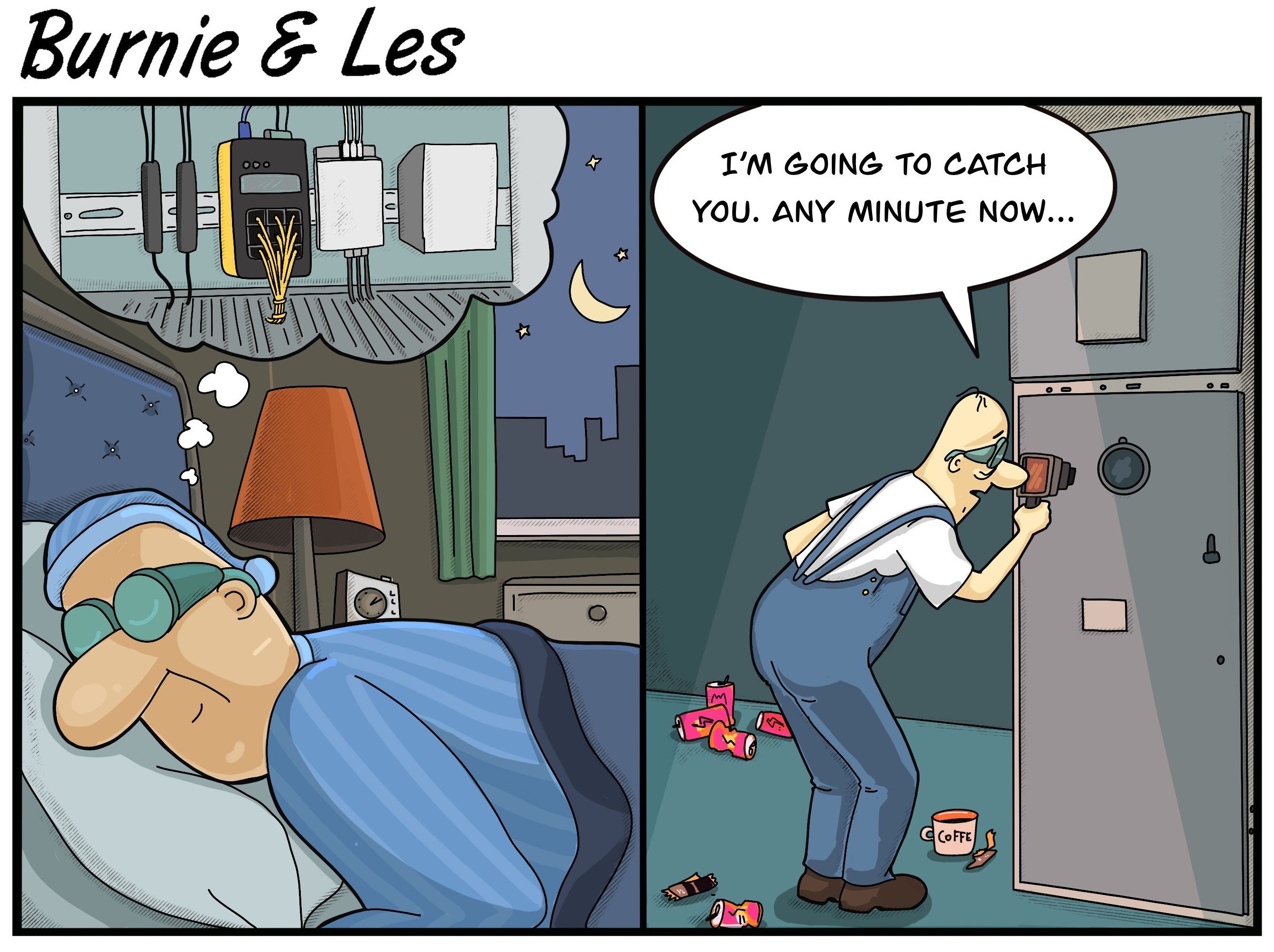

Like Les, you can sleep soundly knowing the Hot Spot Monitor has you covered. While you have peace of mind knowing the device logs, alarms, and enables you to trend temperature variations that are indicative of a potential fault, you certainly won't want to imagine life without a Hot Spot Monitor like Burnie here. It will always keep on eye on your equipment so Burnie doesn't have to.

For more on the Hot Spot Monitor, learn how this device complies with NFPA 70B in the video below:

At Grace, reliability and electrical safety is not just our business; it's our mission. When your mission is to minimize downtime, our GraceSense predictive maintenance solutions have the answer. Check out this FREE eBook that explores the cost-benefit analysis of predictive maintenance, uptime strategies, causes of electrical failures, and more.

In other news, our Chief Technology Officer, Andy Zimmerman, was recently a guest on the Empowering Pumps & Equipment podcast. Andy discusses the importance of predictive maintenance and the Industrial Internet of Things. Get to know what Andy does on a daily basis and how his background landed him in the IIoT space at Grace Technologies (interview starts at 25:10). Check it out below!

About Empowering Industry Podcast: Empowering Pumps & Equipment is the information and connection hub for pump and related equipment industries and has been for the past 9 years. Their mission is to connect, inform and educate, and we are launching a weekly podcast to compliment their existing digital and print platforms.

Stay SAFE and have a have a GREAT week!