The results are in and this year's OSHA top 10 most cited violations have been published. As we close out the year, learn why Lockout/Tagout (LOTO) landed on the wall of shame in 2022.

This standard outlines the minimum performance requirements for the control of hazardous energy during servicing and maintenance of machines and equipment. Taking the #6 spot on the list, LOTO received a total of 2,175 violations this year; 505 more than in 2021. We're excited to introduce new solutions to help you avoid these citations, but for now, let's look at this year's violations in more detail.

“OSHA’s annual Top 10 list helps define trends so safety professionals can find the appropriate solutions,” said Lorraine Martin, National Safety Council President and CEO. “Despite advancements in workplace safety, we continue to see the same types of violations each year. It’s more important than ever employers seek education and resources to keep their workers safe.”

Speaking of which, we strive to be a leading educator and resource for employers seeking to keep their employees safe. Whether you have attended our webinars, followed our blogs, or worked one-on-one with a representative from Grace, you know how important it is for us to demonstrate and prove how you can make your electrical safety and maintenance programs safer, smarter, and more productive. With that in mind, here is a breakdown of the most cited LOTO violations from this year and how to avoid them.

1910.147(c)(4): Energy control procedure. – 638 violations

Procedures shall be developed, documented, and utilized for the control of potentially hazardous energy when employees are engaged in the activities covered by this section.

Companies can find that by providing a documented LOTO procedure and ensuring employee training and compliance, they will see a reduced risk that directly results in greater efficiency and productivity while complying with OSHA regulatory requirements.

“Lockout” procedures refer to written steps that are taken to bring the machine to a zero energy state. Once a de-energized condition is established, locks are placed on energy isolation devices that enable personnel to maintain control over the hazardous energy. “Tagout” devices are meant to show that the equipment is in a de-energized state and maintenance is being performed on it.

When combined together, the procedure “Lockout/Tagout” refers to lockout devices and identification tags being used in conjunction to indicate that a qualified person is safely performing an energy-isolated task. When employees follow the LOTO procedures enforced by the companies they work for, they are able to better protect themselves from unexpected re-energization or the release of stored energy.

1910.147(c)(7): Training and communication. – 434 violations

The employer shall provide training to ensure that the purpose and function of the energy control program are understood by employees and that the knowledge and skills required for the safe application, usage, and removal of the energy controls are acquired and demonstrated by employees, and documented by the employer.

While OSHA requires that all authorized and affected employees receive periodic training, the implemented training program at any organization can be customized to meet precise needs. However, companies training their employees to meet the minimum compliance standards does not result in achieving maximum safety and productivity.

Today, it’s possible for the implementation of a LOTO program to complement OSHA standards by enhancing compliance through the use of Permanent Electrical Safety Devices (PESDs). By installing PESDs wherever LOTO procedures are performed, companies can facilitate these additional safety measures into their written LOTO training program to ensure even further reduced risk and increased productivity.

1910.147(c)(6): Periodic inspection. – 338 violations

The employer shall conduct a periodic inspection of the energy control procedure at least annually to ensure that the procedure and the requirements of this standard are being followed.

The three steps to a successful audit program include meeting the appropriate frequency of annual periodic inspections at a minimum, ensuring authorized employees are competently trained to audit, and certifying that the inspections are being performed with proper documentation. An environment that is highly productive and efficient is a culture where employees are secure, safe, and cared for.

According to the U.S. Department of Labor, a safe and healthy workplace not only protects workers from injury and illness, but can also lower injury/illness costs, reduce absenteeism and turnover, increases productivity and quality, and raise employee morale. In other words, safety is not just good practice, it is good for business.

1910.147(c)(1): Energy Control Program – 199 violations

The employer shall establish a program consisting of energy control procedures, employee training, and periodic inspections to ensure before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, startup, or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from the energy source and rendered inoperative.

The purpose of the Energy Control Program is to provide written policies and rules within your safety management system. This regulation addresses the practices and procedures necessary to disable machinery or equipment that will prevent the release of hazardous energy while employees perform servicing and maintenance activities.

If your procedures include PESDs, you can document and provide training on the use and interpretation of these devices as part of the LOTO procedure for the specific equipment they are installed on. PESDs also are available to be installed with custom warning labels. This greatly assists employees when performing LOTO on equipment that features voltage indicators and/or portals by decreasing their risk of exposure to hazardous energy.

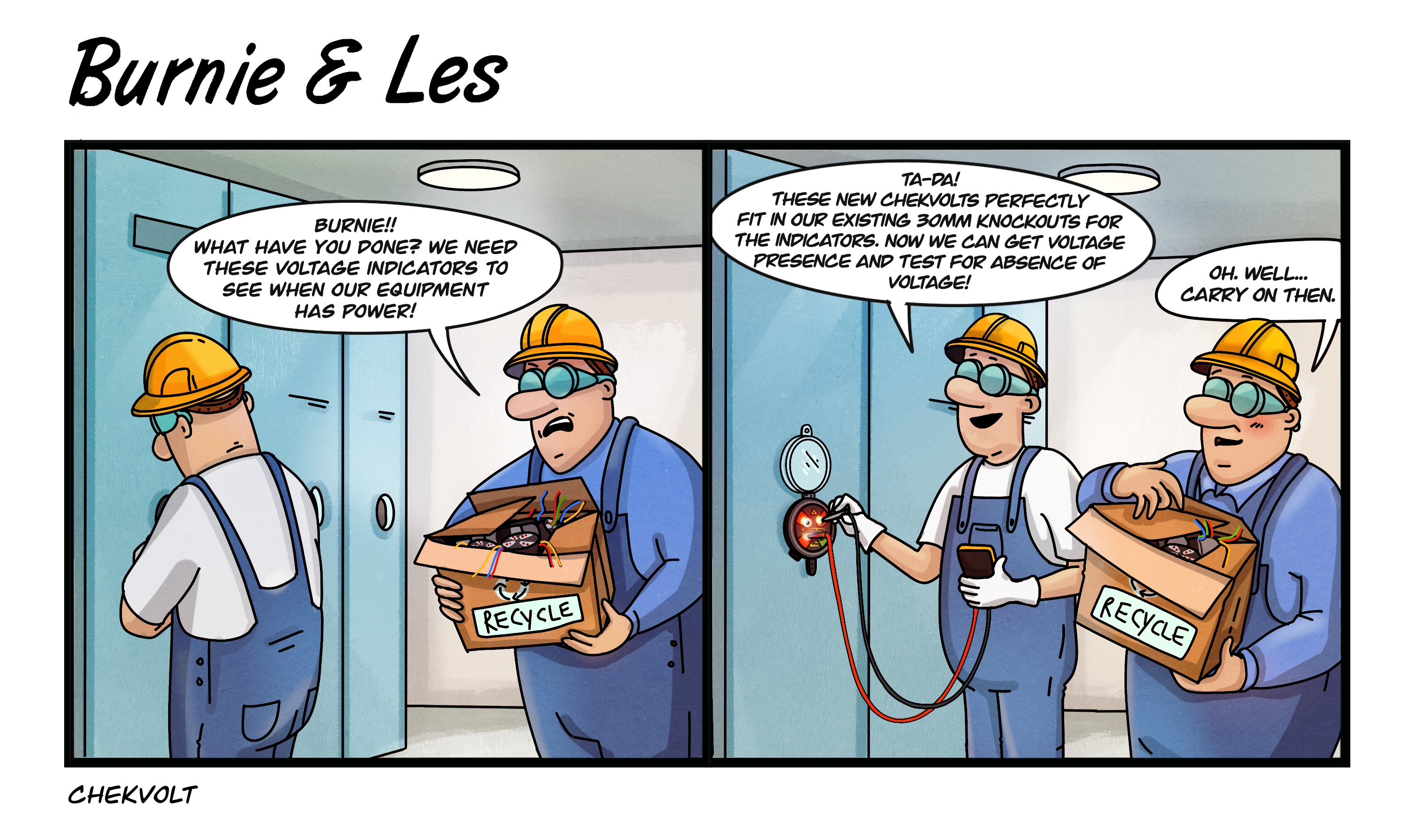

In 2023, we're not only wishing you the best in the new year, but right now we're offering you an opportunity to make this year safer, smarter, and more productive. Our new ChekVolt was engineered with LOTO's infamous track record for compliance in mind. Here's how we help you comply:

- NFPA 70E 120.5(4) – ChekVolt voltage indication LEDs illuminate when hazardous voltage is present until stored electrical energy is released, providing a warning of hazardous voltage that may harm maintenance personnel believing equipment to be in a depowered state.

- NFPA 70E 120.5(7) – ChekVolt high impedance protected test points allow a qualified electrician to safely test phase-to-phase and phase-to-ground for absence of voltage using an adequately rated portable test instrument (i.e. voltmeter). Per 120.5 (7): “Before and after each test, determine that the test instrument is operating satisfactorily through verification on any known voltage source.”

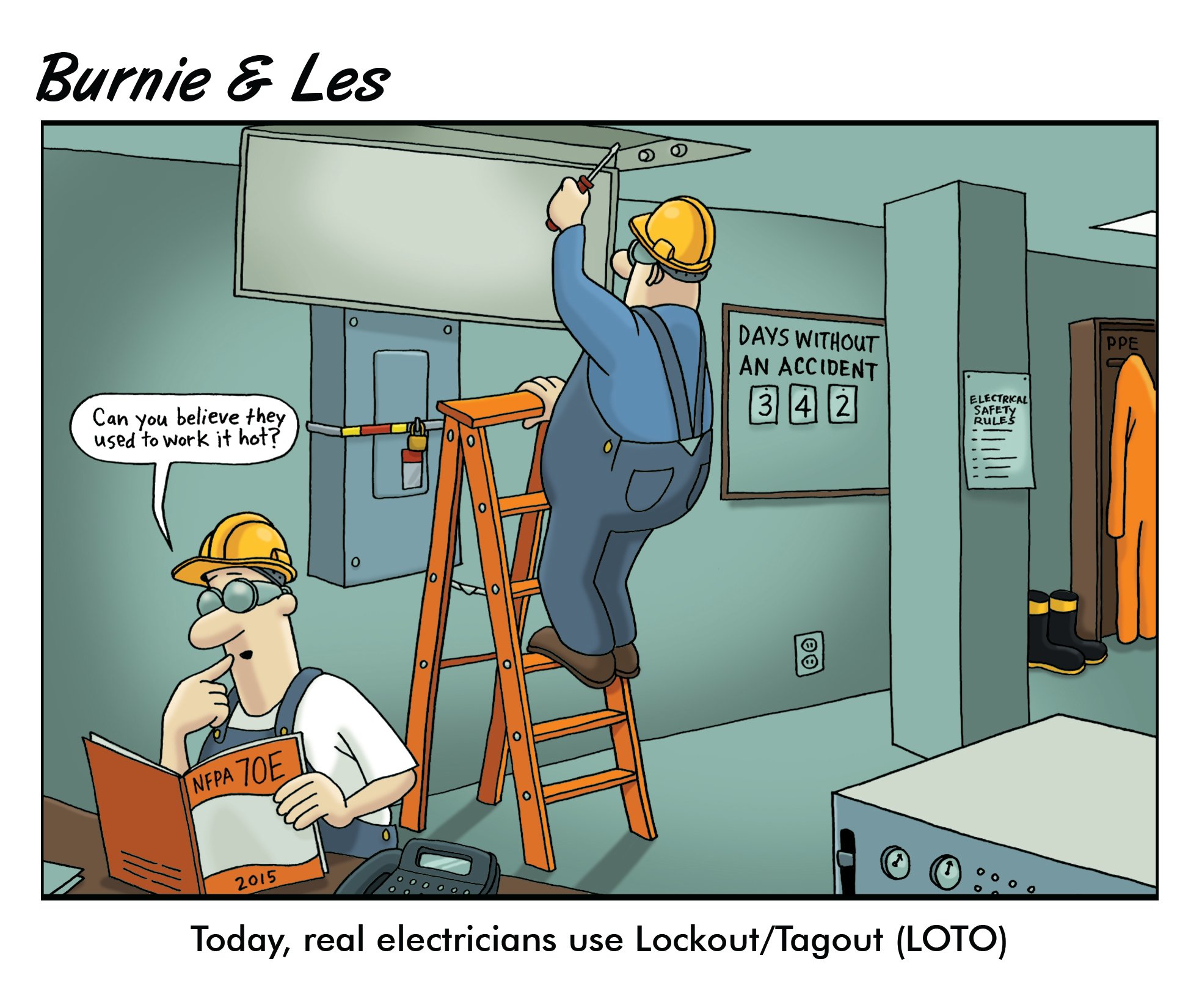

If you're an existing user of our R-3W Series voltage indicators like Burnie & Les here, you can simply swap out your indicator for a ChekVolt in no time. Otherwise, the ChekVolt can be quickly installed through a 30mm knockout and wired directly to the line side or load side via 4 potted lead wire connections. Once installed, reduce your LOTO procedure times by 35-40 minutes. ChekVolt will pay for itself in just 2-3 procedures.

Make it a New Year's resolution to improve your safety and productivity in 2023!