Predict Failures.

Prevent Downtime.

Improve Performance.

Enter GraceSense™

Our Solution Helps You:

Prevent Failures

Reduce downtime and extend

equipment life.Easy Deployment

Quick setup with wireless sensors and gateways.Data-Driven Decisions

Empower maintenance teams with actionable insights.Seamless Integration

Connect with PLCs, SCADA, and CMMS platforms like Studio 5000.Scale & Adapt

Configure sensor and gateway options to meet your specific operational needs.Receive Expert Support

Benefit from our white-glove delivery and support from our team of experts.

Monitor Leading

Failure Indicators

Such as Vibration, Current, Temperature & More

Vibration & Temperature Sensors

Early Anomaly Detection

Wirelessly transmit vibration and temperature data to identify machine malfunctions.

Versatile Installation

Multiple mounting options and easy battery replacement (3–5 year life).

Edge Processing

Built-in analytics for real-time insights without extra hardware.

Seamless Communication

Utilizes IEEE 802.15.4 ZigBee for reliable, low-power data transmission.

Wireless I/O Portals

Third-Party Sensor Integration

Accepts 0–10V, 4–20mA, and RS485 signals for flexible data acquisition.

Configurable Architecture

Accommodates a range of inputs, radios, and power options.

Environmental Protection

IP65-rated enclosure options ensure performance in harsh industrial settings.

Scalable Setup

Easily expand monitoring coverage by adding more portals as needed.

One Powerful Platform.

Three Flexible Gateways.

CloudGate™

Cloud Integration

Bridges sensor data to the cloud-based Maintenance Hub for real-time, browser-based insights.

Flexible Connectivity

Choose Wi-Fi or LTE for fast deployment.

Scalable Architecture

Supports multiple wireless sensors within a 30-meter radius.

ComboGate™

Hybrid Gateway

Combines CloudGate™ and ControlGate™ in one device.

Dual Connectivity

Send data to the Maintenance Hub (LTE/Wi-Fi) while integrating with PLC/SCADA/DCS via EtherNet/IP™ or Modbus TCP/IP.

Comprehensive Coverage

Perfect for plants needing both local and cloud-based insights.

ControlGate™

Plant-Floor Integration

Transmits data directly to PLCs, SCADA, or DCS systems using EtherNet/IP™ or Modbus TCP/IP.

Rapid Deployment

Ideal for facilities needing immediate access to critical data within existing control networks.

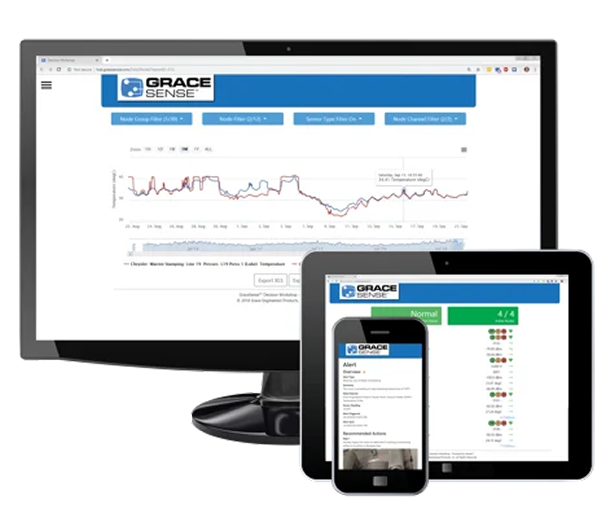

Maintenance Hub

Right Data.

Right Place.

Right Now.

- ssid_chart

Actionable Trends

Utilize our expertise in acceleration, vibration, phase, electromagnetic, and temperature data analysis.

- headset_off

Noise Reduction

Our platform filters out irrelevant signals for more reliable, actionable insights.

- timeline

Real-Time Insights

Continuous monitoring provides up-to-the-minute data to stay ahead of issues.

- lightbulb

Proactive Decision

Understand the big picture to prevent problems, reducing downtime and costs.

- settings_input_antenna

Real-Time Monitoring

Provides live asset statuses with dashboards, trends, and analytics.

- cloud_upload

Cloud or Local Hosting

Available in both cloud-based and

on-premise configurations. - notification_important

Automated Alerts

Sends SMS and email alerts with actionable, step-by-step remediation instructions.

- bar_chart

Custom Reports

Generates detailed reports to track asset performance and maintenance activities.

- multiple_stop

Seamless Integration

Open API for sharing data and alerts with CMMS, SCADA, and DCS systems.

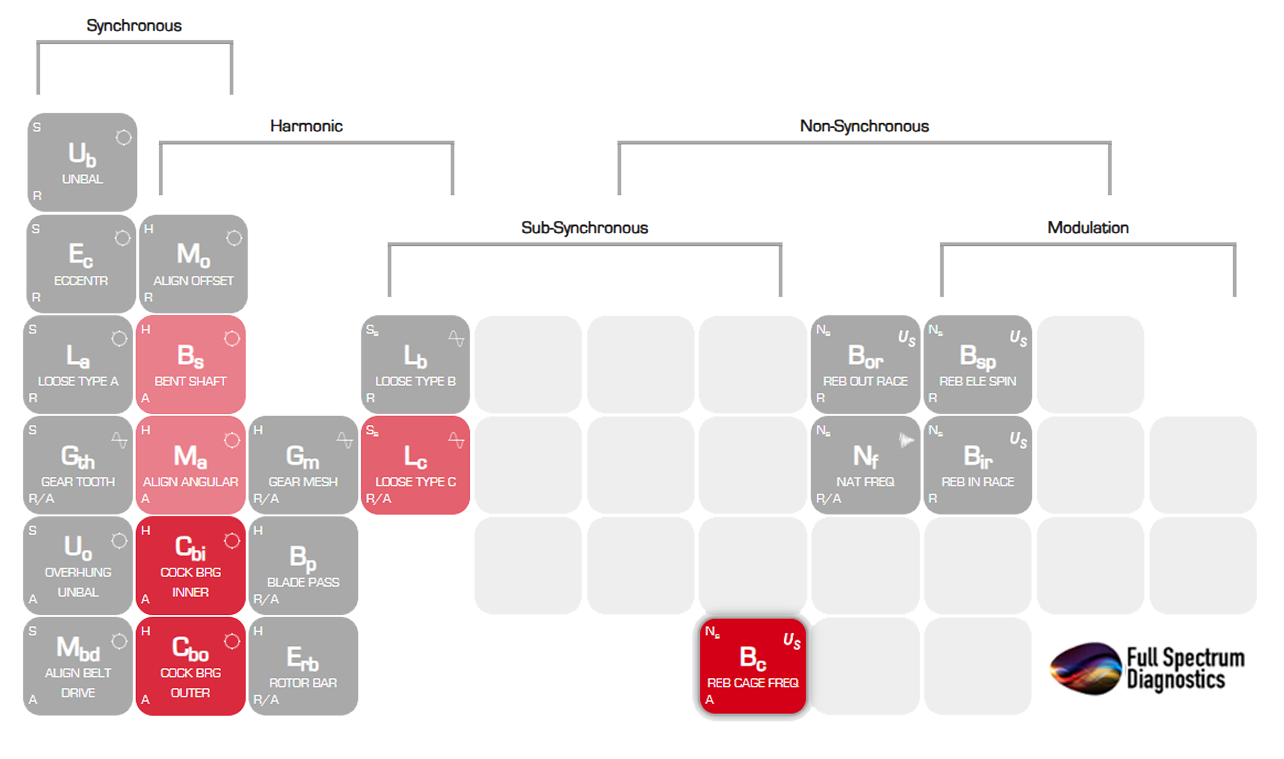

- VBTx Node

Captures detailed vibration data, even in hazardous locations, for precise analysis.

- Defect Classification

Converts vibration data into clear insights, identifying issues like misalignment or bearing failures.

- Real-Time Fault Detection

Monitors assets and alerts teams to faults like unbalance, looseness, and bearing wear.

- Operational Benefits

Boosts predictive accuracy, streamlines maintenance, and supports safety compliance.

The Benefits of

Machine Health

Monitoring

Solutions

Key Benefits Include:

Enhanced

ResponsivenessStay ahead of potential failures and allocate resources efficiently.

Extended

Equipment LifespanPrevent the progression of faults, extend asset longevity, and avoid premature replacements.

Optimized

Maintenance PracticesMinimize unnecessary maintenance tasks, reduce reliance on reactive repairs, and optimize resource allocation.

Maximize

uptime

minimize cost

WITH GraceSense™

- Prioritize Maintenance

Sends SMS and email alerts with actionable, step-by-step remediation instructions.

- Receive Early Warnings

Get critical alerts via SMS, email, or direct integration with your CMMS.

- Optimize Maintenance Spend

Target only the assets that need attention, saving time and money.

- Enhance Safety & Reliability

Reduce unplanned maintenance activities and improve operator safety.

TakeControlWith Expert Support

White-Glove Delivery & Installation

Seamless account setup, data structuring, personalized onboarding, and specialized integration services for a smooth, best-practice configuration.

- build

Customizable

Service PackagesChoose from Free, Silver, or Gold monitoring packages, each designed to suit your unique needs and maximize ROI.

- integration_instructions

Expert

Integration SupportOur IIoT Application Engineers guide you through every step, from Initial Condition Assessment to system deployment and beyond.

- support_agent

Ongoing

Maintenance & SupportEnjoy remote technical support, warranty services, system reviews, and training to ensure your help system stays optimized year-round.

Contact

1515 East Kimberly Road

Davenport, IA 52807

T: 563.386.9596

F: 563.386.9639

Toll Free: 800.280.9517