The last reported OSHA Top 10 violations was in 2019 where the LOTO Standard 29 CFR 1910.147 “Control of Hazardous Energy” placed fourth in OSHA’s Top 10 List of most cited violations with 2,975 total violations; higher than the previous year. This standard outlines minimum performance requirements for the control of hazardous energy during servicing and maintenance of machines and equipment.

Employers cited under this standard failed to establish an energy control procedure either partially or altogether, while others were cited for failing to provide adequate employee training, failing to conduct periodic evaluations of procedures, and failing to use LOTO devices or equipment. These are the top three common mistakes made by employers and employees for Control of Hazardous Energy.

1. 1910.147(c)(4) Energy Control Procedure

Procedures shall be developed, documented and utilized for the control of potentially hazardous energy when employees are engaged in the activities covered by this section.

What makes compliance with the “minimum performance requirements for the control of hazardous energy” fall under the umbrella of common violations? To understand this, we need to start by defining the “LOTO” acronym.

Lockout procedures refer to written steps that are taken to bring the machine to a zero energy state. Once a de-energized condition is established, locks are placed on energy isolation devices that enable personnel to maintain control over the hazardous energy.

Tagout devices are the affixed on machines/equipment that was made prior to the year 1990 where the equipment is not designed with provision to lock, although they do not provide any sort of control or protection other than warning personnel of the imminent hazard.

When combined together, the procedure “Lockout/Tagout” (LOTO) refers to lockout devices and identification tags being used in conjunction to indicate that a qualified person is safely performing an energy isolated task. When employees follow the LOTO procedures enforced by the companies they work for, they are able to better protect themselves from unexpected re-energization or release of stored energy.

Companies can find that by providing a documented LOTO procedure and ensuring employee training and compliance, they will see reduced risk that directly results in greater efficiency and productivity while complying with OSHA regulatory requirements.

2. 1910.147(c)(7) Training & Communication

The employer shall provide training to ensure that the purpose and function of the energy control program are understood by employees and that the knowledge and skills required for the safe application, usage, and removal of the energy controls are acquired by employees.

When it comes to OSHA and LOTO, the code recognizes two categories of people that need training: Authorized & Affected Employees. Under the training mandated to companies by OSHA, “Each authorized employee shall receive training in the recognition of applicable hazardous energy sources, the type and magnitude of the energy available in the workplace, and the methods and means necessary for energy isolation and control. Each affected employee shall be instructed in the purpose and use of the energy control procedure.”

To summarize, “authorized employees” are those who are applying the locks and “affected employees” are those in the area during a lockout. The latter can range anywhere from operators to third-party contractors. If they are within the vicinity of the procedure, they are affected. Ensuring that both authorized and affected employees have been trained is vital to a successful LOTO program.

While OSHA requires that all authorized and affected employees receive periodic training, the implemented training program at any organization can be customized to meet precise needs. However, companies training their employees to meet the minimum compliance standards does not result in achieving maximum safety and productivity.

As evidenced by the record high LOTO violations of 2019, companies need to do more to improve and ensure worker safety and really ask themselves if they’re investing in safety just to satisfy a compliance and avoid fines, or if they are investing in preventing injuries and saving lives.

3. 1910.147(c)(6) Periodic Inspection

The employer shall conduct a periodic inspection of the energy control procedure at least annually to ensure that the procedure and the requirements of this standard are being followed.

Right alongside training and communication lies the follow-up protocol of periodic inspections. You’ve outlined and defined your procedure, trained and retrained your employees, and equipped them with what they need to get the job done safely and efficiently. But it doesn’t end there. Not only do employees come and go, but so does your equipment. Annual auditing is a key component of maintaining your LOTO program in highest regard for safety and productivity.

Periodic inspections/audits will help companies maintain the established procedures to minimize risk along with maintaining compliance, and ultimately protecting the investment of the safety program. The purpose of an annual audit is to verify all required procedure are in place, accurate, effective, and optimized to the ideal lockout process. Inspecting each employee on the proper lockout process and retraining employees is vital in order to achieve effective execution of the program. Companies should also provide comprehensive documentation of these annual audits being conducted and keep these records of dedication to protect their investment in the program, as audit records and documentation are compliance requirements as well.

The three steps to a successful audit program include meeting the appropriate frequency of annual periodic inspections at a minimum, ensuring authorized employees are competently trained to audit, and certifying that the inspections are being performed with proper documentation. When it becomes boiled down to these three components, it begins to become apparent that a large factor of the LOTO Standard 29 CFR 1910.147 “Control of Hazardous Energy” code violations are a direct result of human error and lack of company oversight.

We cover these three pain points and more in this deep dive into the most common electrical safety citations. We've taken an in-depth analysis of the problems that exist today in electrical safety programs. Taking a look at the past, present, and future of our interactions with controlling hazardous energy gave as a clear view of what conversations we need to be having. With OSHA & NFPA 70E coming a long way since their inception, an incredible amount of responsibility is left in the hands of employers to ensure safety among their workforce by not only complying with standards, but even going beyond them. Download today!

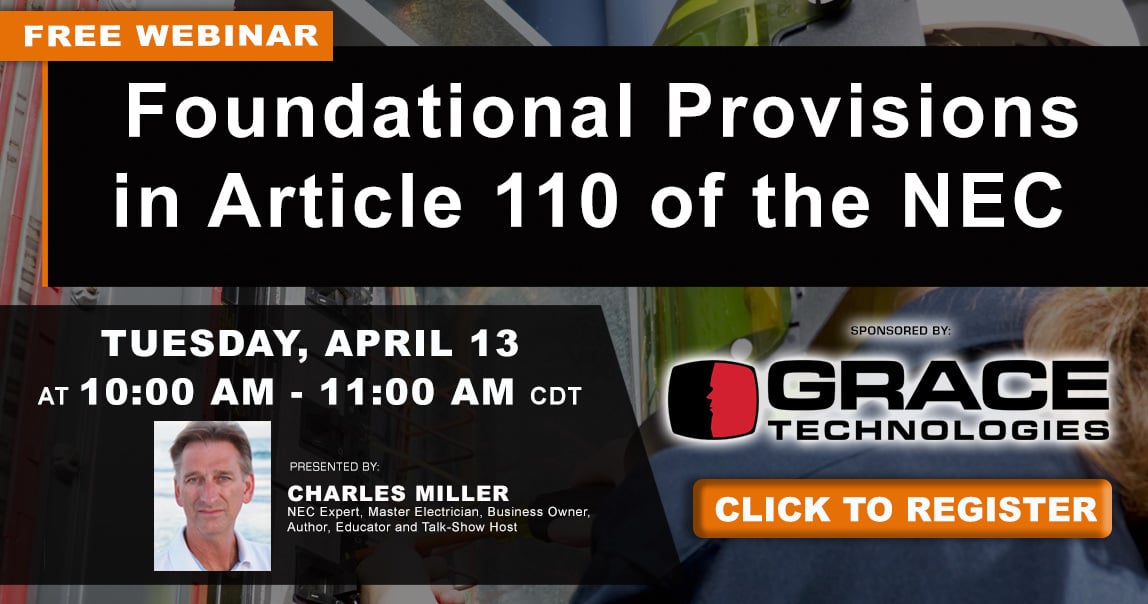

Registration is still open for our next FREE webinar! This session's topic is on Foundational Provisions in Article 110 of the NEC and will be presented by Charles Miller, master electrician, business owner, author, educator, and talk-show host. Click here to register.

Article 110 in the National Electrical Code (NEC) contains general provisions. This webinar will cover Part I, 110.1 through 110.25 in the 2020 edition of the NEC. Some of the topics will included: installation and use of electrical equipment, selective coordination, unused openings, tightening torque, arc-flash hazard warning, identification of disconnecting means, available fault current, and lockable disconnecting means.

Stay SAFE and have a have a GREAT week!