In the complex and hazard-prone environment of industrial settings, arc flash stands out as a formidable risk, capable of causing severe injuries and equipment damage. Understanding and mitigating these risks is not just a safety measure but a necessity. This blog delves into the top strategies and best practices for managing arc flash risks, ensuring a safer workplace for all.

Top 10 Guide to Risk Mitigation & Electrical Safety Best Practices

- Understanding Arc Flash Risks: Arc flash occurs when a significant electrical discharge travels through the air between conductors or from a conductor to the ground, releasing intense energy capable of causing fires, explosions, and severe injuries. Factors leading to arc flash include insulation breakdown, human error, and environmental conditions like moisture or dust.

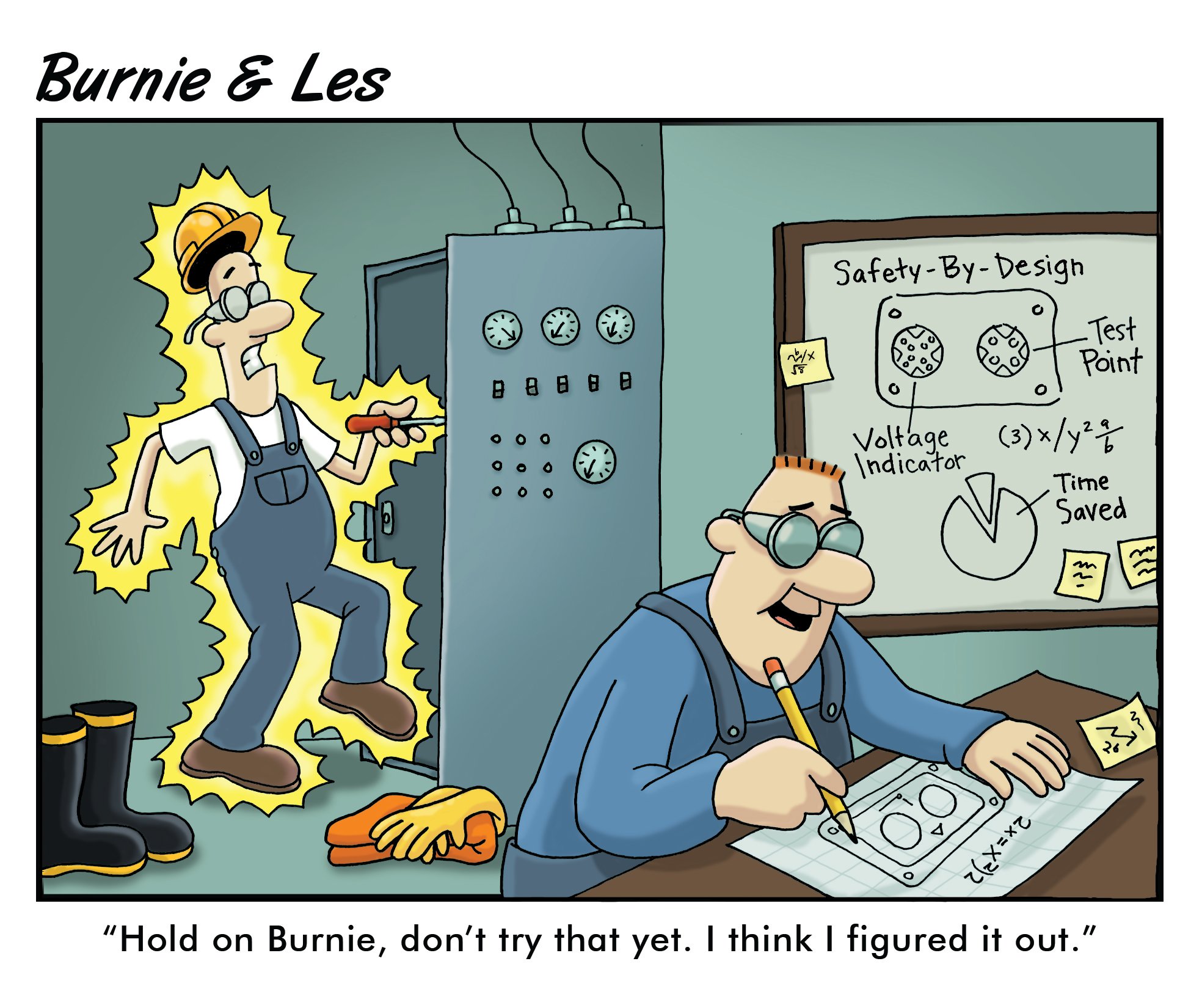

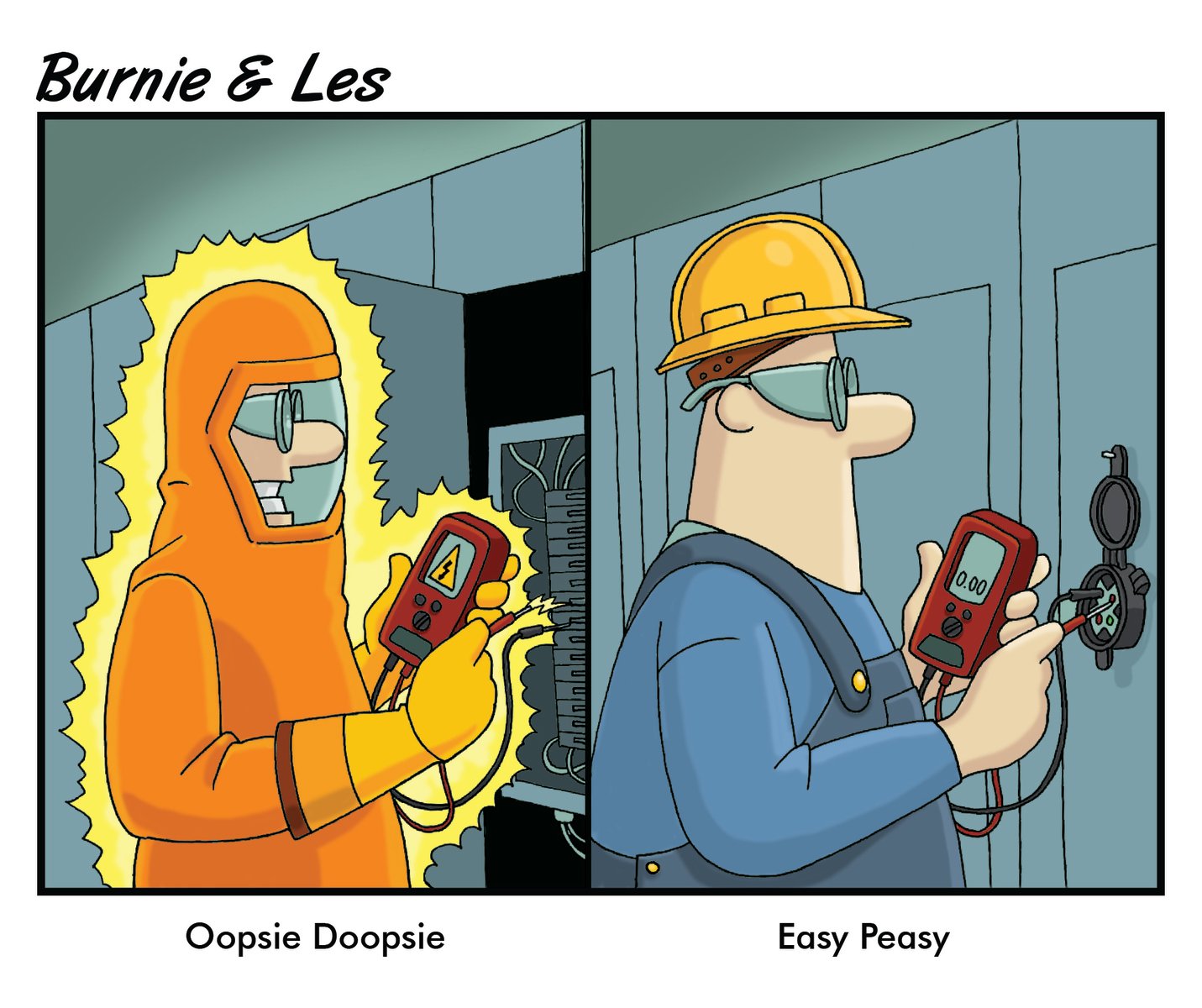

- Arc Flash Energy Reduction: The core of arc flash mitigation lies in reducing the energy involved in an arc flash event. This is achieved by implementing engineering controls that either lower the energy to a safe level or keep workers at a safe distance. Remember, reducing arc flash energy doesn’t eliminate the risk of electric shock, but it does reduce the potential severity of arc flash hazards.

- The Critical Role of Circuit Breakers and Fuses: The duration of the arc is a crucial factor in determining its energy. Therefore, using faster-acting circuit breakers or fuses to clear faults quickly can significantly reduce the risk. This mitigation strategy hinges on the timely interruption of fault currents.

- Coordination Studies: A Key Tool in Mitigation Conducting an Over-Current Protective Device (OCPD) coordination study can optimize device settings, balancing equipment protection and arc flash risk reduction. This study assesses if minor adjustments in device settings can effectively lower incident energy levels while still allowing normal operations.

- Advanced Relaying Techniques: Modern relaying techniques, including the use of optical technology, can quickly identify and clear faults, thereby mitigating arc flash risks. These systems detect arcing faults by observing the flash of light and characteristic current flow associated with these faults.

- Comprehensive Arc Flash Analysis and Labeling: A detailed arc flash analysis is critical for understanding and documenting the current state of an electrical system. This analysis guides the implementation of safety labels on equipment, providing workers with essential information on necessary PPE and safe working distances. NFPA 70E mandates that this study be updated every five years or following significant system changes.

- Developing and Implementing Safety Programs: Creating, documenting, and training staff in safety programs is essential. These programs should be developed with the help of experts in electrical safety and should adhere to standardized processes and guidelines like IEEE 1584. Consistency and professional oversight are key to effective safety programs.

- Ensuring Compliance with NFPA 70E and OSHA Standards: Complying with NFPA 70E and OSHA standards is not just a regulatory requirement but a foundational aspect of electrical safety. These standards provide guidelines for electrical safety in the workplace, including training, PPE requirements, and hazard assessments.

- Passive Line-Side Arc Isolation: Innovations like passive line-side arc isolation modules provide an advanced solution to mitigate arc flash risks. These systems offer isolation between protective zones, minimizing the chance of inadequate protection due to incomplete risk assessments.

- Continuous Improvement: The realm of electrical safety and arc flash mitigation is ever-evolving. Regular reviews, updates to safety protocols, and staying abreast of new technologies and methods are crucial for maintaining and enhancing safety standards.

Permanent Electrical Safety Devices (PESDs) can play a crucial role in mitigating arc flash risks in various industrial settings. PESDs are an integral part of a comprehensive arc flash risk mitigation strategy. They enhance safety by providing essential information about electrical systems, reducing direct exposure to electrical hazards, and supporting compliance with safety standards. Here's how PESDs help in this regard:

-

Voltage Verification: PESDs allow workers to quickly and easily verify the presence or absence of voltage. This is a critical step in ensuring that equipment is de-energized before any maintenance work is performed. By providing a clear indication of the electrical status and high impedance-protected test points, these devices reduce the need for workers to expose themselves to potential hazards.

-

Reducing Exposure to Hazardous Conditions: One of the key principles of electrical safety is to reduce the frequency and duration of exposure to live electrical components. PESDs contribute to this by allowing workers to check the status of electrical equipment without interacting directly with live components. This minimizes the risk of arc flash incidents which can occur during manual testing or inspection.

-

Enhancing Lockout/Tagout (LOTO) Procedures: PESDs complement traditional LOTO procedures by providing visual or other forms of confirmation that energy isolation has been effectively implemented. This adds an extra layer of safety to the LOTO process, ensuring that all energy sources are properly isolated before maintenance begins.

-

Compliance with Safety Standards: The use of PESDs can help facilities comply with relevant safety standards, such as NFPA 70E, which outlines best practices for electrical safety in the workplace. These standards often emphasize the importance of using appropriate tools and devices to ensure worker safety.

-

Promoting a Culture of Safety: Incorporating PESDs into electrical safety protocols not only enhances physical safety but also helps in building a culture of safety within the organization. When workers see that their safety is a priority, reflected in the investment in safety devices and training, it fosters a more conscientious and safety-oriented work environment.

-

Facilitating Safe Maintenance and Inspections: PESDs make routine maintenance and inspections safer by reducing the need for direct interaction with potentially hazardous electrical components. This can lead to more frequent and thorough inspections and maintenance activities, as the risk factor is significantly reduced.

Arc flash poses a significant risk in industrial environments, demanding a multifaceted approach for effective mitigation. Incorporating strategies and best practices such as the ones outlined, along with utilizing PESDs as an additional layer of protection, can significantly enhance safety protocols. PESDs are instrumental in providing reliable voltage verification and supporting safe maintenance practices, thereby reducing the risk of arc flash incidents.

By integrating these methods with conventional safety measures, industries can better safeguard their personnel and equipment. To stay updated and safe in arc flash risk mitigation, stay tuned to industry updates here on the blog and consult the full texts of sources like IEEE standards, NFPA 70E, and OSHA guidelines. This approach ensures a well-rounded and robust defense against the dangers of arc flash.

.gif?width=2296&height=1208&name=R3MT-VI-Social-Media-Ads-2212_Flashing6%20(1).gif)

Experience the difference in arc flash risk mitigation with a firsthand look at the ChekVolt. Request your free sample today and discover how this innovative device not only enhances safety but also boosts productivity in your electrical safety procedures. Witness ChekVolt's unique ability to minimize arc flash hazards while streamlining LOTO processes, setting a new standard in workplace safety.

As we wrap up our insightful journey through the world of arc flash mitigation and electrical safety, we invite you to take your knowledge even further. Join us for our 2024 kickoff webinar, a pivotal event designed to deep dive into the critical aspects of electrical safety in the upcoming year.

Why Attend Our Webinar?

-

Deep Dive into NFPA 70E 2024 Edition: The NFPA 70E standards are evolving, and our webinar will provide an essential guide on navigating the latest changes in the 2024 Edition. Understanding these updates is crucial for staying compliant and ensuring safety in your workplace.

-

Learn from OSHA’s Most Cited LOTO Violations of 2023: We'll analyze the most cited Lockout/Tagout (LOTO) violations by OSHA in 2023, offering valuable insights into common pitfalls and how to avoid them in your safety practices.

-

Special Emphasis on GracePESDs Integration: Discover how integrating Grace Permanent Electrical Safety Devices (PESDs) can enhance compliance and safety in your electrical protocols, especially in light of the new 'Point of Work' changes.

-

Practical Strategies for Enhanced Safety: Equip yourself with actionable strategies and best practices for robust LOTO procedures, aligning with the latest NFPA 70E updates and OSHA standards.

This webinar is perfect for electricians, safety managers, facility operators, and anyone keen on elevating their LOTO procedures and embracing the updated NFPA standards. It’s an opportunity not just to learn but to transform your approach to electrical safety for a safer, smarter, and more productive year ahead. Register now for our 2024 kickoff webinar and join us in setting a new standard in electrical safety excellence.