As the realm of industrial automation grows more complex, the tools we rely upon to ensure streamlined operations and safety are evolving. Among these, the Panel Interface Connector (PIC) stands out as a vital link between technicians and the intricate world inside control panels. If you've yet to familiarize yourself with the transformative power of PICs, this journey into their functionalities and benefits will unveil why they're quickly becoming indispensable in industrial applications.

How Does a Panel Interface Connector Work?

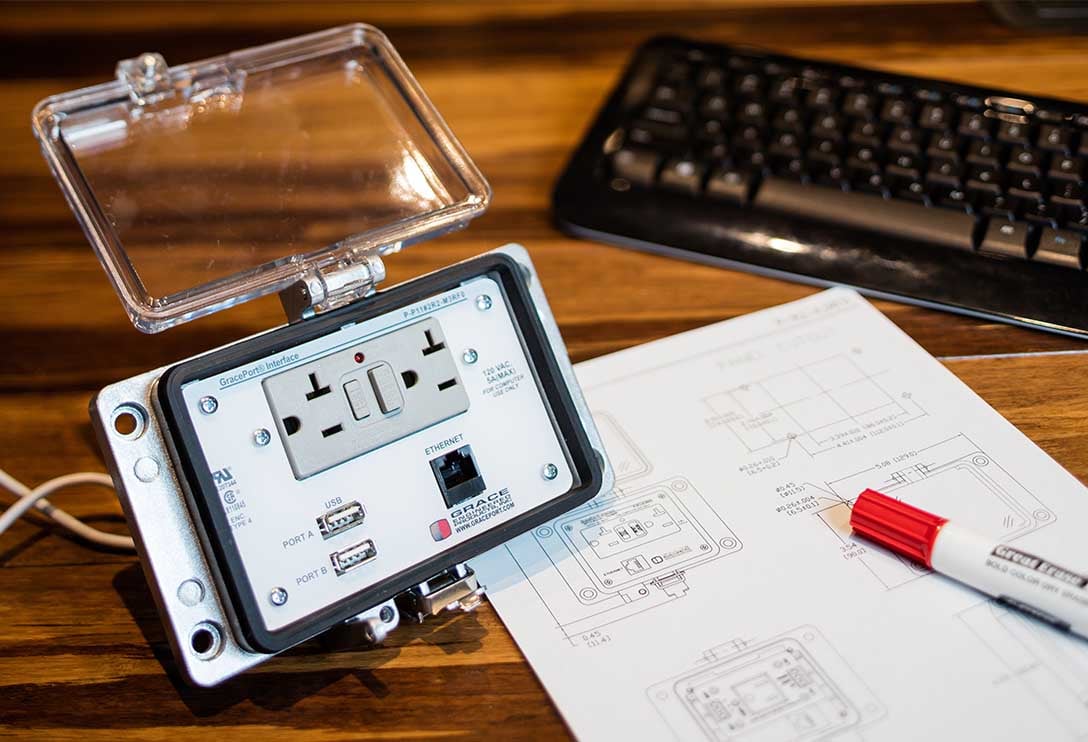

A PIC is a device that acts as the gateway between the exterior of an enclosure or control panel and its internal components. By accessing the PIC, users can interface with the equipment inside without ever opening the control panel. This can involve tasks such as programming, troubleshooting, or monitoring various components.

The Rationale Behind Using a Panel Interface Connector

Opening an industrial control panel isn't as simple as flipping a switch. Each time a panel is accessed, there's a risk associated with potential electrical hazards, including the dreaded arc flash. PICs virtually eliminate this danger by allowing access to the machinery's inner workings without exposing the user to the live components inside. It's a marriage of convenience and safety.

Advantages of Integrating a Panel Interface Connector

- Safety: As mentioned, the primary advantage of using a PIC is the substantial increase in safety. By using the connector, maintenance personnel are less exposed to the direct risks of electrical shock or arc flash incidents.

- Efficiency: Maintenance and diagnostics become more streamlined as there's no longer a need to power down the machine or remove the panel cover to access the equipment inside.

- Versatility: Modern PICs, especially those from renowned brands like GracePort, offer a wide array of connection types, ensuring compatibility with a vast range of devices and equipment.

Applications Spanning Industries

PICs aren't limited to one specific industry or application. Their utility spans across various sectors, including manufacturing, energy, pharmaceutical, and more. Wherever there's a control panel or machinery that requires external interfacing, a PIC can potentially be integrated. PICs are widely used across various industries, including:

- Manufacturing: In the manufacturing industry, PICs are commonly used for connecting to PLCs, allowing for efficient programming, maintenance, and troubleshooting.

- Energy: In the energy sector, PICs are used for connecting to control systems in power plants, substations, and other facilities, enabling safe and efficient operations.

- Pharmaceutical: In pharmaceutical facilities, PICs are used for accessing control systems in production and quality control processes, ensuring compliance with regulations and efficient operations.

- Food and Beverage: In the food and beverage industry, PICs are used for accessing control systems in production lines, ensuring efficient operations and compliance with food safety standards.

- Water and Wastewater: In the water and wastewater industry, PICs are used for accessing control systems in treatment plants, pumping stations, and other facilities, enabling safe and efficient operations.

Prioritizing Safety with Panel Interface Connectors

One of the most significant concerns in any industrial setting is the risk of an arc flash – a type of electrical explosion resulting from a low-impedance connection to the ground or another voltage phase in an electrical system. It's not only deadly but can also cause severe damage to equipment. Here's where PICs shine. By using a PIC, the need to open a panel, which can instigate an arc flash, is drastically reduced.

GracePort: A Choice of Excellence

Now that we’ve unpacked the brilliance of Panel Interface Connectors, the next step is choosing a top-tier provider. GracePort’s meticulous design, emphasis on user safety, and commitment to customization make it a prime choice for industrial professionals everywhere.

Customizing with GracePort

The world of PICs becomes even more intriguing when we delve into customization. GracePort, an industry leader, offers unparalleled configurations tailored to your exact needs. Whether it's specific components, power options, or even adding special custom text or your company logo to the faceplate, GracePort ensures your PIC is as unique as your application.

Unlocking Safety and Productivity

Incorporating the right tools and technologies is crucial in the industrial realm. A Panel Interface Connector, especially one from a trusted brand like GracePort, can be a transformative addition to your operations. So why wait? Unlock enhanced safety, efficiency, and versatility with a PIC.

Elevate your knowledge even further. Dive deep into the world of industrial control panels and their safety with our comprehensive ebook: "Making Industrial Control Panels Safer and More Productive." It's time to arm yourself with the information and tools that set industry leaders apart.

Join us for an insightful webinar as we delve into the world of Predictive Maintenance (PdM) in the manufacturing and automotive industries. Discover how our GraceSense PdM System has empowered organizations to achieve remarkable success by proactively addressing equipment failures and optimizing maintenance practices.

Through real-life case studies and success stories, we will showcase the transformative impact of GraceSense in improving operational efficiency, reducing downtime, and maximizing equipment reliability. Don't miss this opportunity to explore the cutting-edge features and benefits of GraceSense and gain valuable insights to elevate your maintenance strategies.

Learning Objectives:

- Understand the role of predictive maintenance in driving success in manufacturing and automotive industries.

- Explore real-life case studies showcasing the impact of GraceSense PdM System on reducing downtime and improving equipment reliability.

- Gain insights into the key features and benefits of GraceSense and learn how to leverage them to optimize maintenance practices in your organization.