The Power of Medium Voltage Continuous Thermal Monitoring

As summer gradually comes to a close, facilities around the globe are making the most of their scheduled shutdowns, investing in upgrades that align with the ever-evolving landscape of digital transformation. One of the most significant shifts in the electrical industry is the growing emphasis on medium voltage continuous thermal monitoring that holds immense value for the safety and efficiency of electrical systems. Here’s why.

Digital Transformation in the Electrical World

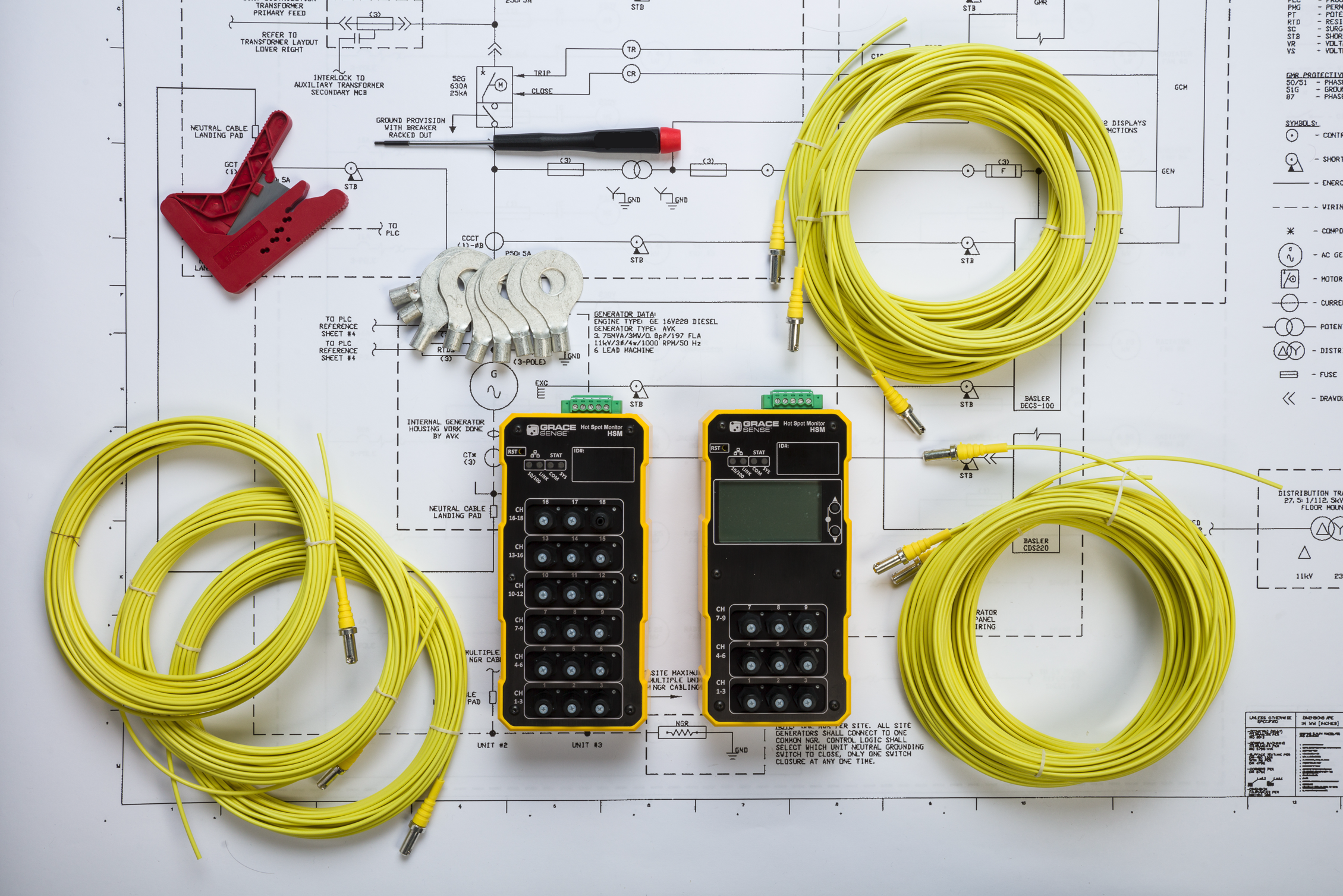

The digital era is here, transforming industries by offering smarter, more efficient, and safer ways of doing things. For the electrical world, this means leveraging technology to monitor, predict, and prevent electrical anomalies. And in the heart of this transformation is the GraceSense™ Hot Spot Monitor.

Why the Emphasis on Medium Voltage Continuous Thermal Monitoring?

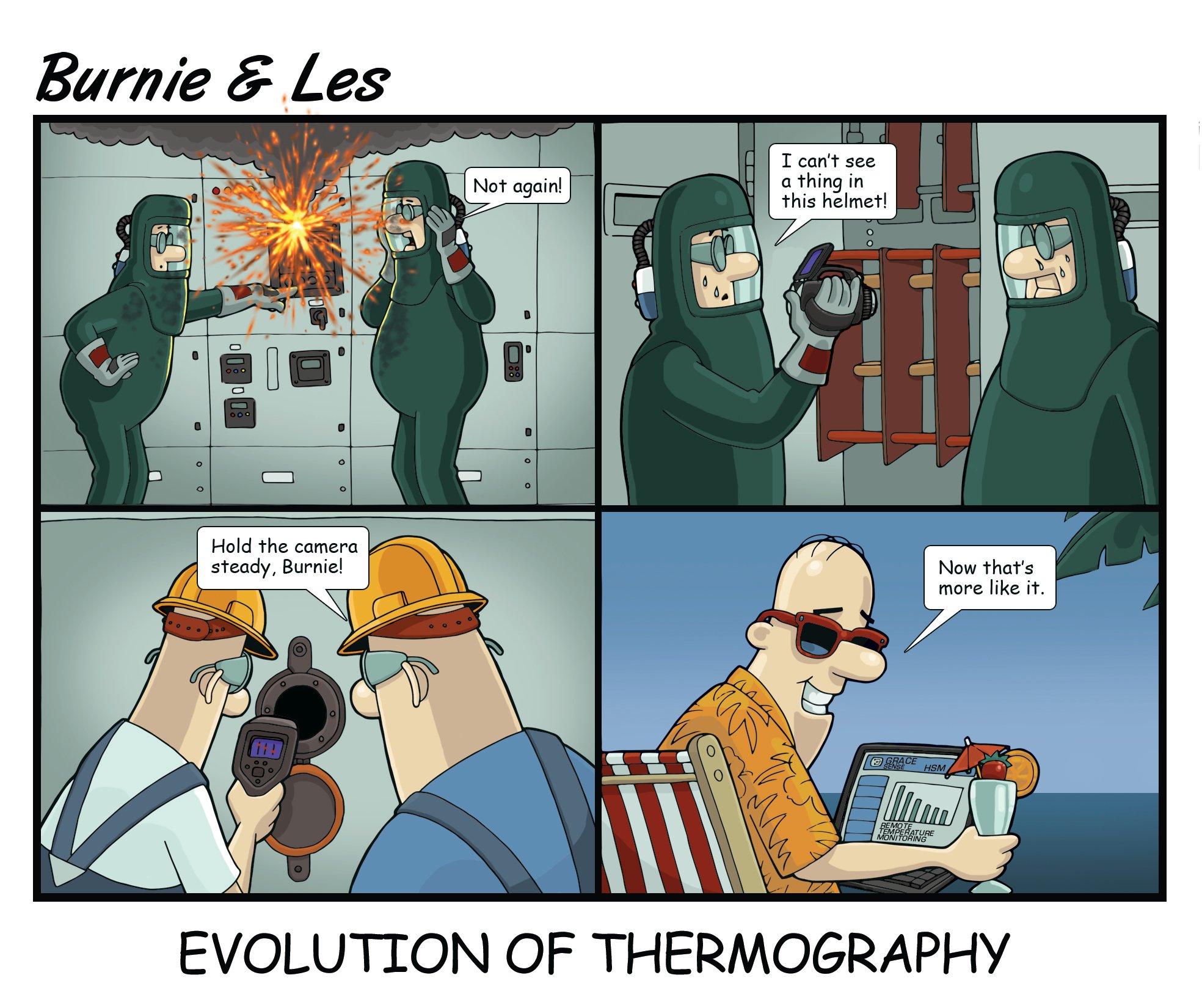

Understanding temperature fluctuations in electrical connections is crucial for preventing potential faults. However, periodic monitoring or manual inspections expose personnel to safety risks and don't provide real-time data. This is where medium voltage continuous thermal monitoring comes into play.

With the Hot Spot Monitor, facilities can continuously track temperature variations in critical electrical connections, particularly in medium voltage settings. By doing so, they significantly reduce the chances of unforeseen shutdowns, equipment damage, and safety hazards.

Seizing the Shutdown Opportunity

Now, the challenging part — the installation. The GraceSense™ Hot Spot Monitor necessitates a scheduled downtime for installation, making summer shutdowns an ideal window of opportunity. However, considering the narrow timeframes for these shutdowns, it's essential to leverage them wisely.

Switchgear installations, for example, often require an entire plant to be offline. By coordinating the installation of the Hot Spot Monitor with other maintenance activities during these planned outages, facilities can minimize disruptions and maximize the efficiency of the downtime.

Reaping the Benefits

Post-installation, the advantages of integrating the Hot Spot Monitor are numerous:

- Safety By Design: No more exposure risks during routine open-door thermography inspections.

- Predictive Maintenance: Integrating with a facility’s Electrical Preventive Maintenance (EPM) program, the Hot Spot Monitor assists in predicting potential faults, allowing timely interventions.

- Remote Monitoring: With cloud connectivity, the device provides data right at your fingertips, accessible anywhere, anytime.

- Long-term Savings: Prevent unplanned shutdowns, reduce equipment damage, and avoid hefty repair costs.

The Future is Continuous Monitoring

While the initial shift towards digital transformation requires investments in time and resources, the payoffs, in the long run, are immense. Embracing mediums like continuous thermal monitoring today sets facilities up for a safer, more efficient tomorrow.

Remember, as industries evolve and technology advances, it's the early adopters who reap the maximum benefits. If you haven’t considered integrating technologies like the GraceSense™ Hot Spot Monitor, now is the time. Harness the power of medium voltage continuous thermal monitoring and lead your facility into the future of electrical safety and efficiency.

Are you ready to revolutionize your facility's electrical maintenance strategy? Dive into our comprehensive GraceSense eBook: A Proactive Approach to Electrical Maintenance. Explore in-depth insights on continuous remote monitoring, thermal monitoring applications, the transformative power of the Hot Spot Monitor, and compelling statistics that underscore the urgency and benefits of a proactive stance.

Unlock the future of electrical maintenance. Grab your copy now and embark on a journey towards safer, more efficient, and predictive electrical solutions.

Come and see the Hot Spot Monitor (and more!) in person this week! The IEEE Petroleum and Chemical Industry Committee (PCIC) invites you to the 70th annual conference in New Orleans, LA, from September 11th to 14th, 2023. Explore the world of electrical engineering with 61 technical papers covering the latest in petroleum, chemical, and mining industries. Network with global experts, attend practical tutorials and contribute to industry standards. Visit us at Studio 8 and be part of this premier event. See you in New Orleans!