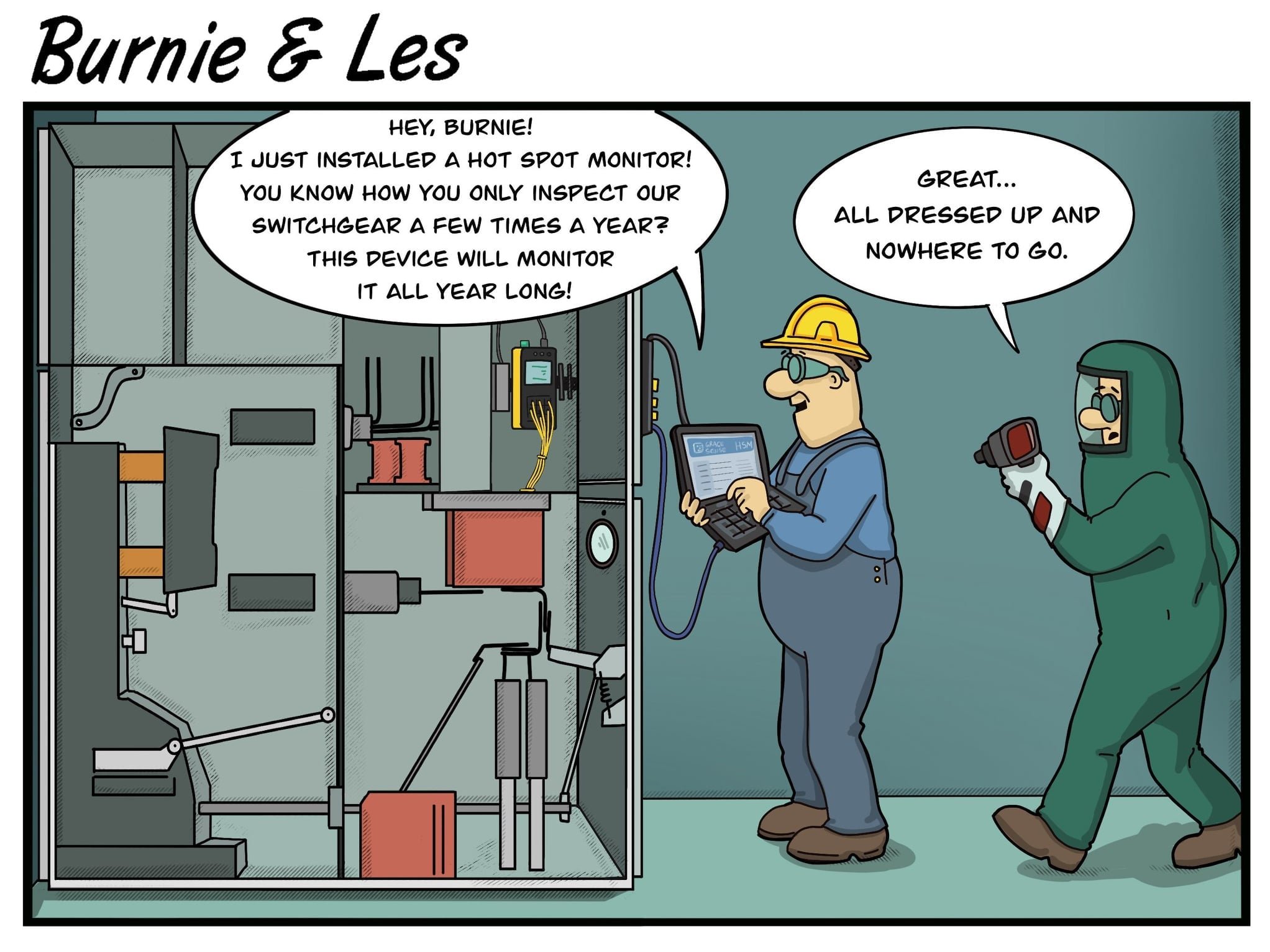

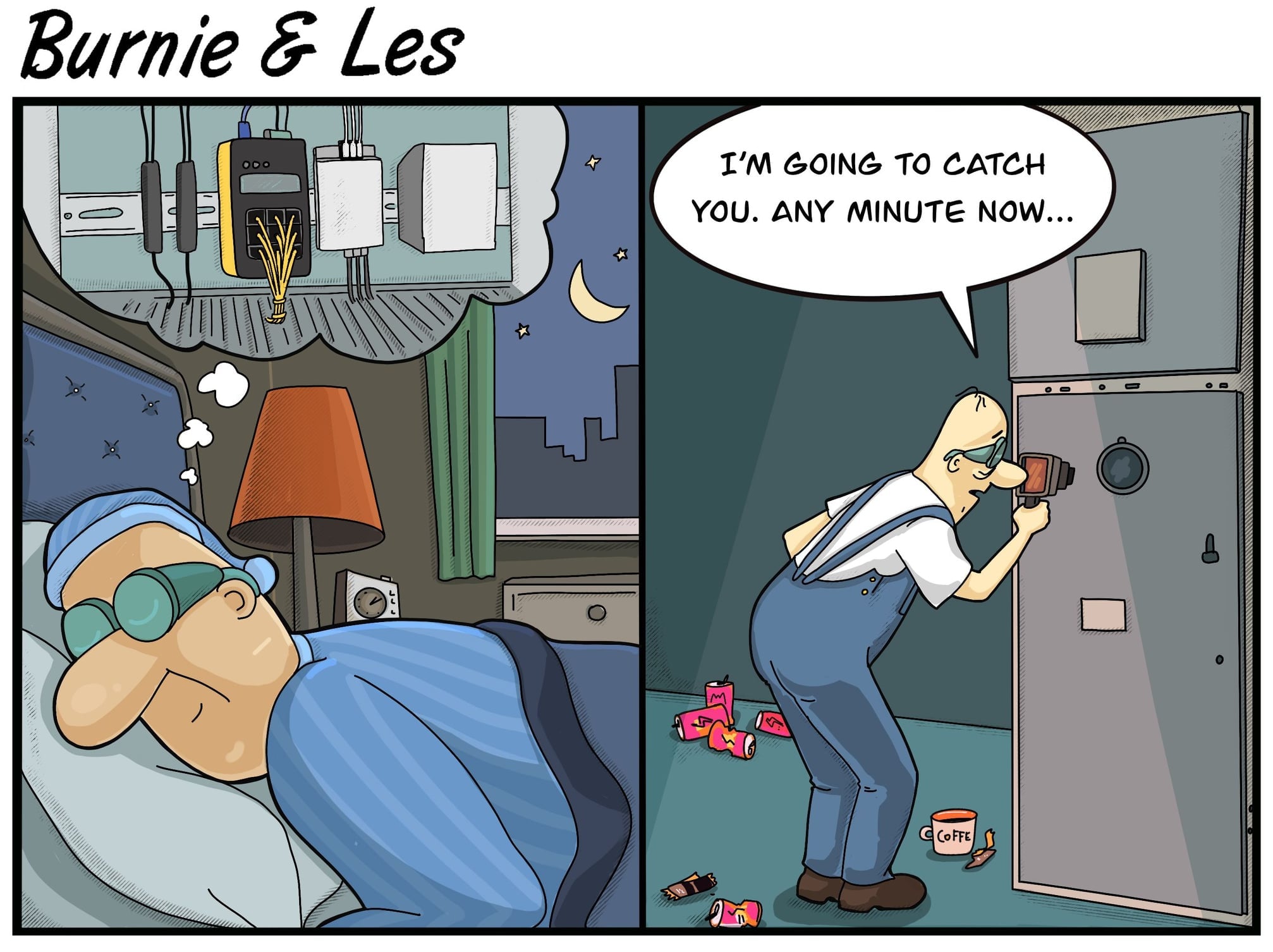

The best way to catch something in the act is to be watching at all times. Routine thermography inspections on critical equipment, such as MCCs and Switchgears, have become safer and more productive with advancements in continuous monitoring. Our Hot Spot Monitor will help you keep a close eye on your critical assets safely, remotely, and reliably.

Employers are responsible for providing a safe and reliable workplace, but everyone is responsible for upholding the integrity of the workplace standards for preventing injuries and failures. You can have excellent personnel safety and still have a major accident. Safety is improved by disciplined operating and maintenance practices. Take the following steps to learn how you can achieve higher workplace safety and productivity standards today:

Step 1: Aim for Zero Risk through Training

Start by shooting for the moon. When your goal is to aim for zero risk, you'll land amongst the stars. The first step towards setting an aspirational goal is to set one that seems unrealistic. Your team needs to work really hard to get there and you're going to do everything you can to move in that direction.

It’s important to note that the operations and maintenance training should be on a par with your safety training, as typically they are not. Getting both reliability and safety to their full potential requires operational discipline and the tenacious use of this practice in all areas. Never stop improving or communicating. One of the leading breakdowns of safety in any organization is complacency.

Step 2: It's not in the Budget? Focus on the Little Things

The most common excuse for not investing in safety and reliability is “budget”. You probably think you don’t have it because you think you need millions of dollars. You don’t have to start big just to start improving somewhere. Pick something, any machine, and make the maintenance routine right. When you've got that one done, move onto the next piece of equipment. Solidify that safety and proactive approach and pay it forward.

It's a gradual process but over the course of a year or so you'll start to build enough credibility to the leadership team to look more into investing in safety and reliability. This is about a change in mindset, a change in the approach to engage in the workforce and set higher disciplinary standards for the workforce itself, higher expectations, and then supporting them meeting that expectations. All this is really a question of leadership.

Step 3: Set Goals for Engagement & Alignment

Eliminating small day-to-day problems has a much bigger impact on results then focusing on the major failures. Engaged employees are three times more productive than average. Most organizations are not aligned, engaging, or helping their employees do a better job. Focus on the high-level goals and think at a systems level. Develop shared measures between competing groups and partnership agreements so you are more likely to work together. You have to have clear goals that are reasonably achievable.

An environment that is highly productive and efficient is a culture where employees are safe, secure, and cared for. A safe and healthy workplace not only protects workers from injury and illness, but it can also lower injury/illness costs, reduce absenteeism and turnover, increase productivity and quality, and raise employee morale.

Step 4: Embrace Continuous Condition Monitoring

With condition monitoring, the goal is to understand the degradation process to avoid or minimize the consequence of failure so we're monitoring. The ability to identify faults before they occur saves money when unplanned outages, service interruptions, and equipment failures are avoided entirely with predictive maintenance monitoring.

Installation of the Hot Spot Monitor is simple and serves as a suitable alternative to periodic thermography inspections as it will continuously monitor potential hot spots and enable users to predict failures in electrical equipment, leading to scheduled out maintenance. That time interval in between potential and functional failure is the time we have to take action to plan and schedule or to mitigate the failure or to avoid the failure altogether.

Experience higher workplace safety and productivity with continuous remote temperature monitoring. The GraceSense™ Hot Spot Monitor will continuously monitor temperature at your critical connection points in equipment such as switchgears. You'll immediately get alerted when the temperature drops below or rises above your programmed thresholds, indicating there may be a problem that could lead to costly downtime. Don't wait until your periodic inspection to find out there's a problem you could have fixed a long time ago. Download the eBook to learn how to take "A Proactive Approach to Electrical Maintenance!

Registration is now open for our next FREE webinar. Basics of Gear Analysis will be presented by Dan Ambre, PE. Ambre is the founder and principal engineer at Full Spectrum Diagnostics. The FSD Machinery Analysis Division specializes in Experimental Modal Analysis (EMA) and Operating Deflection Shape (ODS) machinery diagnostics. Our Vibration Training and Certification Division makes use of these unique analyses by incorporating them into our course materials for a “real-life” training experience.

This webinar will define important spectrum and time waveform parameters for a successful gear analysis. The attendee will learn proper Gear Meshing Frequency (GMF) calculations, how to calculate shaft rotational speeds and the importance of gear tooth counts. The attendee will also learn how to set proper frequency band alarms for gear box trending.

Stay SAFE and have a have a GREAT week!