This week, in honor of National Electrical Safety Month, we are shedding light on the significance of electrical safety in the water/wastewater industry. With population growth and limited resources for potable water, ensuring continuous uptime is crucial. However, maintenance and downtime pose risks, making safety and efficiency paramount.

Minimizing Downtime Risks

In the water treatment industry, the significance of minimizing downtime risks cannot be overstated, particularly when the interruption of service can leave an entire population without water. With reactive maintenance scenarios being a leading cause of injuries, it becomes imperative to prioritize safe and efficient maintenance practices. Minimizing downtime risks and exploring solutions will ensure continuous uptime while safeguarding the water supply for communities.

- Downtime in water treatment plants can lead to the loss of water for an entire population.

- Reactive maintenance scenarios contribute to 70% of injuries, emphasizing the need for safe and efficient maintenance practices.

Lockout/Tagout (LOTO) Challenges

The implementation of LOTO procedures is crucial for ensuring electrical safety in treatment plants. However, challenges often arise, leading to missteps and potential OSHA violations. Moreover, the traditional approach to LOTO procedures in treatment plants can be time-consuming and requires the involvement of two personnel. Innovative solutions to streamline and enhance the effectiveness of these procedures will ensure the highest level of safety while minimizing disruptions in water treatment operations.

- LOTO, a vital procedure, often encounters missteps, resulting in OSHA violations.

- Traditional LOTO procedures in treatment plants can be time-consuming, involving two personnel.

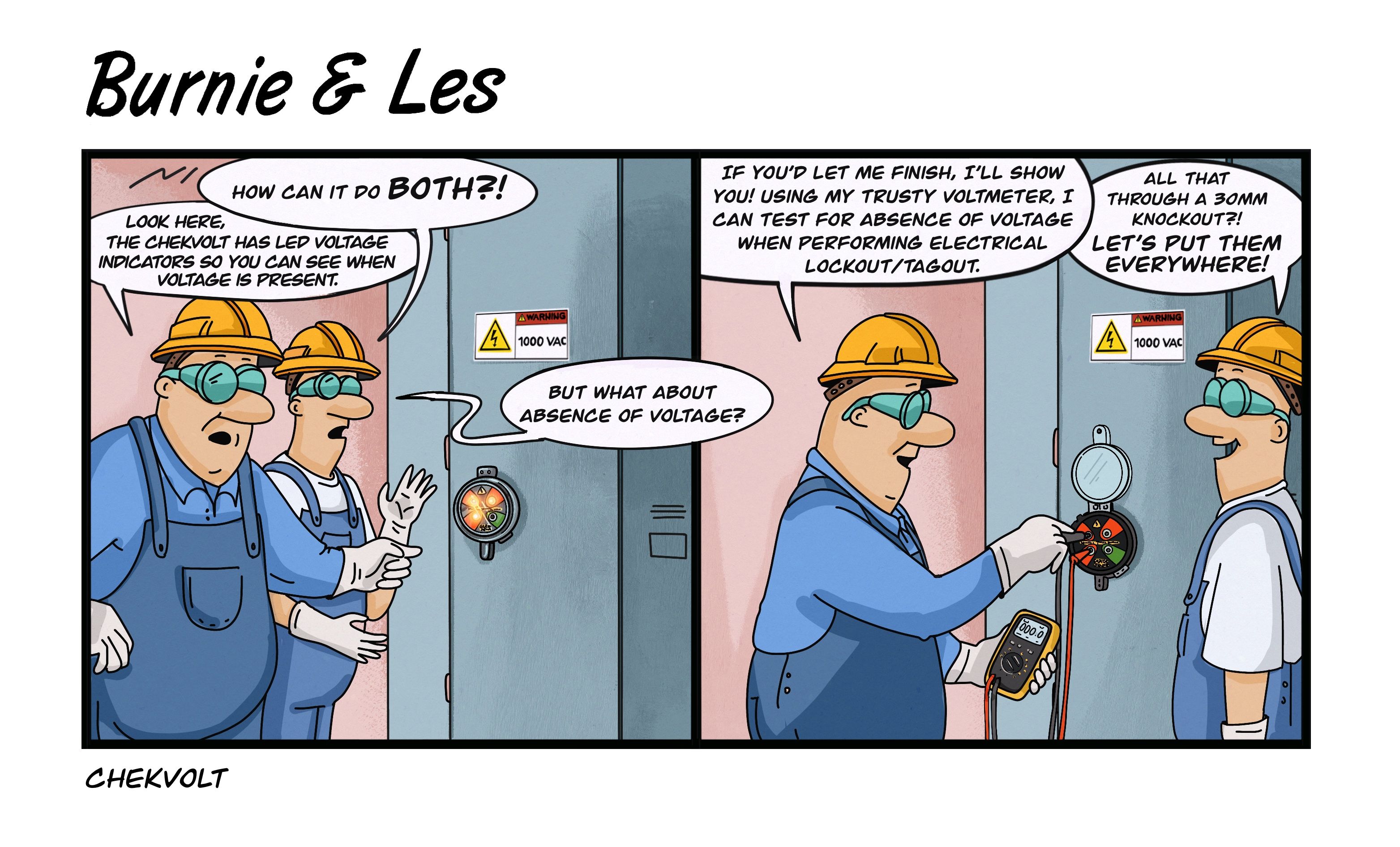

The Role of ChekVolt Permanent Electrical Safety Device (PESD)

When it comes to electrical safety, compliance with regulations is crucial. However, forward-thinking companies understand that going beyond mere compliance can significantly enhance both safety and productivity. In this section, we will explore the role of the ChekVolt and how it offers innovative solutions to improve LOTO procedures. By installing ChekVolt onto enclosures, companies can reduce LOTO procedure times, enable safer absence of voltage tests, and mitigate hazardous electrical exposure risks. The ChekVolt revolutionizes LOTO procedures, creating a safer and more efficient work environment.

- Installing ChekVolt onto enclosures reduces LOTO procedure times by 35-40 minutes.

- ChekVolt allows a qualified electrician to perform absence of voltage tests safely and efficiently from the outside.

- Hazardous electrical exposure risks are mitigated, enabling a single electrician to complete the procedure in less than 5 minutes.

Cost Savings and Safer Access

In addition to enhancing safety, companies are always seeking ways to improve efficiency and reduce costs. When it comes to electrical safety, cost savings, and safer access go hand in hand. This section focuses on the significant benefits of ChekVolt installation in terms of cost savings and improved access to critical equipment. By implementing ChekVolt, companies can experience substantial cost reductions, as the device quickly pays for itself after just a few procedures.

The need for two personnel to visit each lift station is eliminated, transforming a time-consuming task into a swift 5-minute process. ChekVolt's voltage indication feature provides an extra layer of protection by alerting personnel to any unexpected energized components, effectively preventing hazardous incidents. Companies can achieve cost savings and safer access simultaneously through the adoption of ChekVolt.

- ChekVolt installation leads to significant cost savings, paying for itself after just a few procedures.

- The device eliminates the need for two personnel to visit each lift station, reducing a 1-hour task to 5 minutes.

- ChekVolt's voltage indication warns personnel of any unexpected energized components, preventing hazardous incidents.

Features and Compliance

When it comes to choosing electrical safety devices, it is essential to consider the features and compliance aspects that align with industry standards. In this section, we will delve into the remarkable features of ChekVolt, a compact device designed to enhance electrical safety. Equipped with LED voltage presence indication and capable of handling voltages up to 1000V, ChekVolt provides clear visibility of energized components.

Installation is seamless, requiring only a single 30mm knockout, and the device includes high impedance-protected test points for safer absence of voltage testing. Furthermore, ChekVolt is specifically designed to work directly with a qualified electrician's multimeter, ensuring compliance with NFPA 70E guidelines.The ChekVolt facilitates safer absence of voltage testing while meeting rigorous industry standards.

- ChekVolt is a compact device with LED voltage presence indication, suitable for up to 1000V.

- It is installed through a single 30mm knockout and provides high impedance-protected test points.

- Designed to work directly with a qualified electrician's multimeter, ChekVolt ensures safer absence of voltage testing while complying with NFPA 70E guidelines.

Take the first step towards enhancing electrical safety in your water/wastewater facility. Request a sample of the ChekVolt today and experience the benefits firsthand. Don't miss this opportunity to improve LOTO procedures, reduce downtime, and protect your personnel. Follow the link below now to request your ChekVolt sample and start making your maintenance safer, smarter, and more productive.

.jpg?width=2296&height=1208&name=Automate%20Social%20Media%202305%20(1).jpg)

We are excited to announce that we will be exhibiting at Automate 2023 in Detroit next week! As a leading automation showcase in North America, Automate provides a platform for industry professionals to explore the latest advancements and trends in automation. At our booth (#1641), we will be showcasing our innovative solutions, including the GracePESDs ChekVolt, GracePort panel interface connectors, GraceSense Hot Spot Monitor, and the GraceSense Predictive Maintenance System.

Don't miss the opportunity to see our cutting-edge technologies in action and learn how they can enhance safety, productivity, and efficiency in your industry. Join us at Automate 2023 and be part of the automation revolution!

Are you passionate about electrical safety and interested in enhancing workplace safety in your industry? Join us for an insightful and engaging webinar where we will delve into the critical topics of electrical safety, Lockout/Tagout (LOTO) best practices, and the benefits of Permanent Electrical Safety Devices (PESDs). This webinar is a fantastic opportunity to gain expert insights, discover innovative solutions, and ask your burning questions about electrical safety in the workplace.

Don't miss out on this valuable event that can help you prioritize safety, increase productivity, and protect lives. Register now and be part of our mission to make maintenance safer, smarter, and more productive. Together, let's pave the way for a safer and more secure work environment!