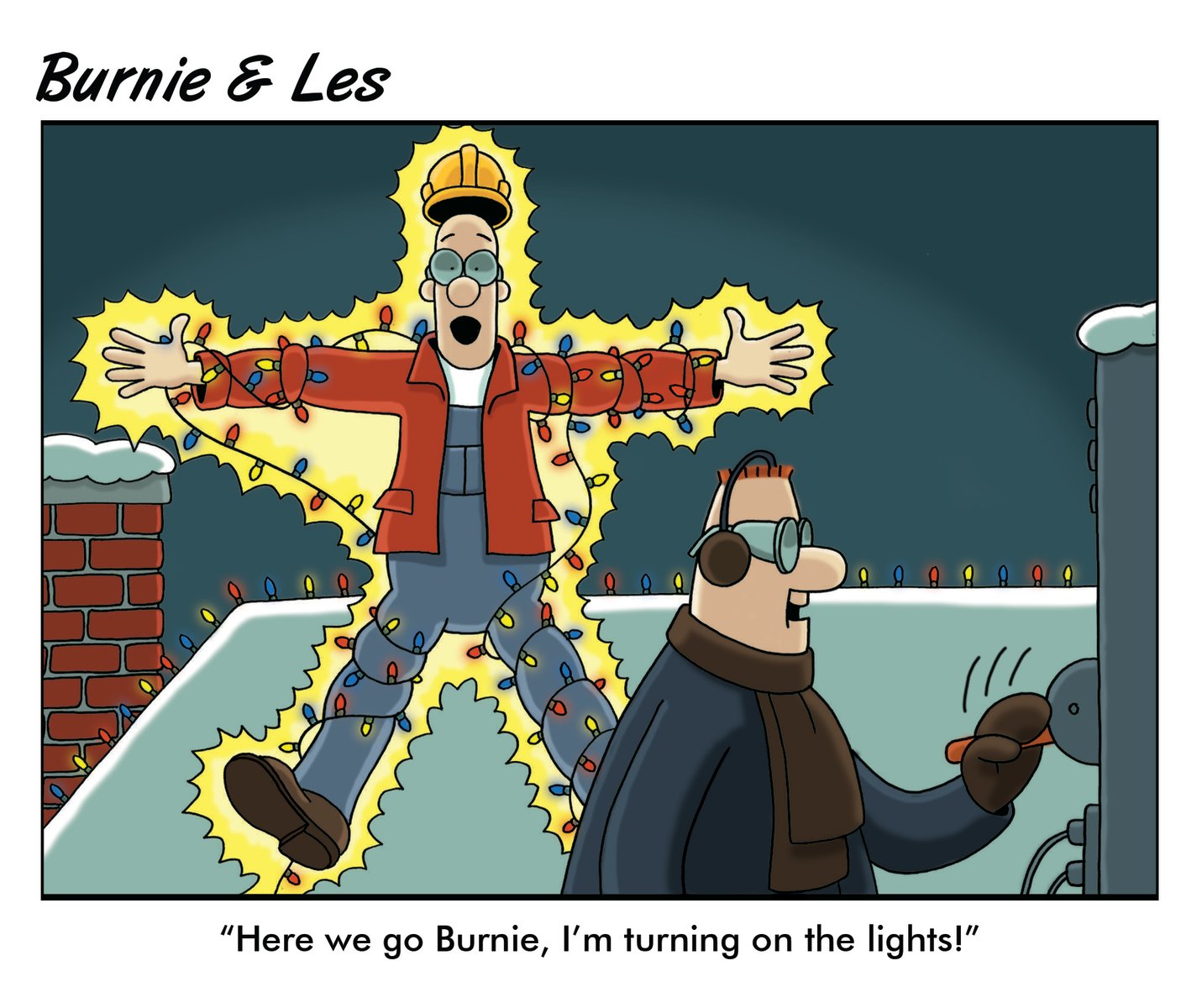

Christmas may be over but like Santa, the Occupational Safety and Health Administration (OSHA) is always watching. OSHA recently announced its list of most frequently cited workplace safety standards for fiscal year 2023. At the 2023 NSC Safety Congress & Expo, OSHA Region 6 Administrator Eric Harbin presented these findings, revealing persistent safety concerns across various industries. With OSHA's recent announcement of the most frequently cited workplace safety standards for 2023, it's a perfect moment to unwrap the state of your safety protocols, and we're here to help you with your Lockout/Tagout (LOTO) procedures.

Unwrapping OSHA's Top 10 Citations of 2023

This year, OSHA's checking its list to see who's been compliant and who hasn't. While 'Fall Protection' continues to top the list, LOTO violations have unfortunately seen a significant rise, from 2,175 in FY 2022 to 2,554 in FY 2023. Lorraine Martin, NSC president and CEO, remarked on the recurring nature of these violations, highlighting the need for renewed focus and solutions in these areas.

In a significant shift from previous years, OSHA has bolstered its enforcement capabilities, signaling a new era in workplace safety compliance. Recent reports from BNA indicate a 19% growth in the number of OSHA inspectors in fiscal year 2022, ending a period of stagnation and marking the highest staffing levels in decades. This increase, a fruition of the additional funding received in FY 2020, has substantially enhanced OSHA's capacity for on-site inspections and enforcing the Occupational Safety and Health (OSH) Act.

With this influx of officers, we're witnessing a shift towards more aggressive enforcement and heightened penalties. As new compliance officers gain experience and proficiency in identifying workplace violations, the likelihood of on-site inspections has significantly increased.

For employers, this means it's crucial to be "inspection ready." Understanding and adhering to safety standards, especially with recent updates and changes, is more important than ever. We recommend collaborating with OSHA counsel to ensure that inspections are conducted lawfully and are both limited and focused.

The Gift of Safety: Understanding LOTO

LOTO procedures are critical in preventing accidental machine activation during maintenance – a vital aspect in the workshop of any industry. The increase in violations highlights an urgent need to revisit and reinforce these safety measures. Just like ensuring each light on the tree is working properly, ensuring each part of your LOTO procedure is compliant is essential for a safe working environment.

According to OSHA 1910.147(b), lockout is "the placement of a lockout device on an energy isolating device, in accordance with an established procedure, ensuring that the energy isolating device and the equipment being controlled cannot be operated until the lockout device is removed. A lockout device is "a device that utilizes a positive means such as a lock, either key or combination type, to hold an energy isolating device in a safe position and prevent the energizing of a machine or equipment. Included are blank flanges and bolted slip blinds."

Tagout is "the placement of a tagout device on an energy isolating device, in accordance with an established procedure, to indicate that the energy isolating device and the equipment being controlled may not be operated until the tagout device is removed." A tagout device is "a prominent warning device, such as a tag and a means of attachment, which can be securely fastened to an energy isolating device in accordance with an established procedure, to indicate that the energy isolating device and the equipment being controlled may not be operated until the tagout device is removed."

GracePESDs: Your Little Helpers in Enhancing Compliance

Permanent Electrical Safety Devices (PESDs) are instrumental in making LOTO procedures safer, more efficient, and easier to comply with in the following ways:

-

Enhanced Safety:

- Voltage Verification: PESDs provide a means to verify the absence of voltage without exposing workers to the direct hazards of testing live circuits. This reduces the risk of electrical accidents like arc flash and shock hazards during LOTO.

-

Increased Efficiency:

- Time Savings: By allowing for quicker and more reliable verification of an electrically safe work condition, PESDs can significantly reduce the time needed for LOTO procedures.

- Ease of Use: PESDs are designed to be user-friendly, often requiring less time to set up and use compared to traditional voltage testing methods.

-

Easier Compliance:

- Clear Indications: PESDs like the ChekVolt provide clear, visual indicators (such as LED lights) for the presence of voltage. This makes it easier to comply with safety standards that require voltage verification as part of LOTO.

- Documentation and Training: The use of PESDs can simplify the documentation required for LOTO procedures and the training process for personnel, as these devices often have straightforward operating procedures.

-

Consistent Application:

- Standardization of Procedures: Incorporating PESDs into LOTO protocols can standardize safety procedures across various equipment and worksites, ensuring consistent application of safety practices.

-

Adaptability:

- Versatility for Different Systems: PESDs are designed to work with a range of electrical systems and applications, making them versatile tools for ensuring safety in various industrial environments.

By integrating PESDs into LOTO procedures, organizations can not only enhance the safety and efficiency of these critical safety processes but also ensure better compliance with occupational safety standards like NFPA 70E and OSHA regulations.

.gif?width=2296&height=1208&name=R3MT-VI-Social-Media-Ads-2212_Flashing6%20(1).gif)

ChekVolt: Lighting Up Your Path to Safety and Productivity

Performing LOTO safely requires the answer to one question; is there voltage? NFPA 70E/CSAZ462 requires an absence of voltage test to verify an electrically safe work condition. The traditional process poses arc flash and shock hazards to comply with NFPA 70E Article 120.6: Process for Establishing and Verifying an Electrically Safe Work Condition. The ChekVolt allows you to test absence of voltage and provides voltage presence indication; all without opening the enclosure door.

PESD users report LOTO procedure time reductions of 35-40 minutes. ChekVolt® pays for itself after 2-3 LOTO procedures from time savings alone. This touch-safe, compact PESD® features voltmeter compatible test points and redundant LED voltage presence indication rated up to 1000 VAC/VDC. The ChekVolt is quickly installed through a single 30mm knockout and includes four lead wires potted in the construction–making LOTO in even the harshest environments safer, smarter, and more productive. Here's how the ChekVolt helps you meet the standard with no exceptions:

- NFPA 70E 120.6(4): The ChekVolt's voltage indication LEDs illuminate in the presence of hazardous voltage, providing a clear warning and enhancing safety for maintenance personnel.

- NFPA 70E 120.6(7): With its high impedance protected test points, ChekVolt allows a qualified electrician to safely test for the absence of voltage. This feature aligns perfectly with the NFPA standard, which mandates verifying the test instrument before and after each test.

Looking Ahead: A Resolution for Safety

As we enjoy the festive season and look forward to the New Year, let's make a resolution to enhance our electrical safety practices. Implementing PESDs like ChekVolt can be a significant step towards ensuring a safer, more compliant 2024. Next week, we'll take a deep dive into OSHA's LOTO violations and provide expert guidance on how to avoid them!

From all of us here at Grace, we wish you a safe, joyful, and compliant holiday season. May your days be merry, bright, and electrically safe!