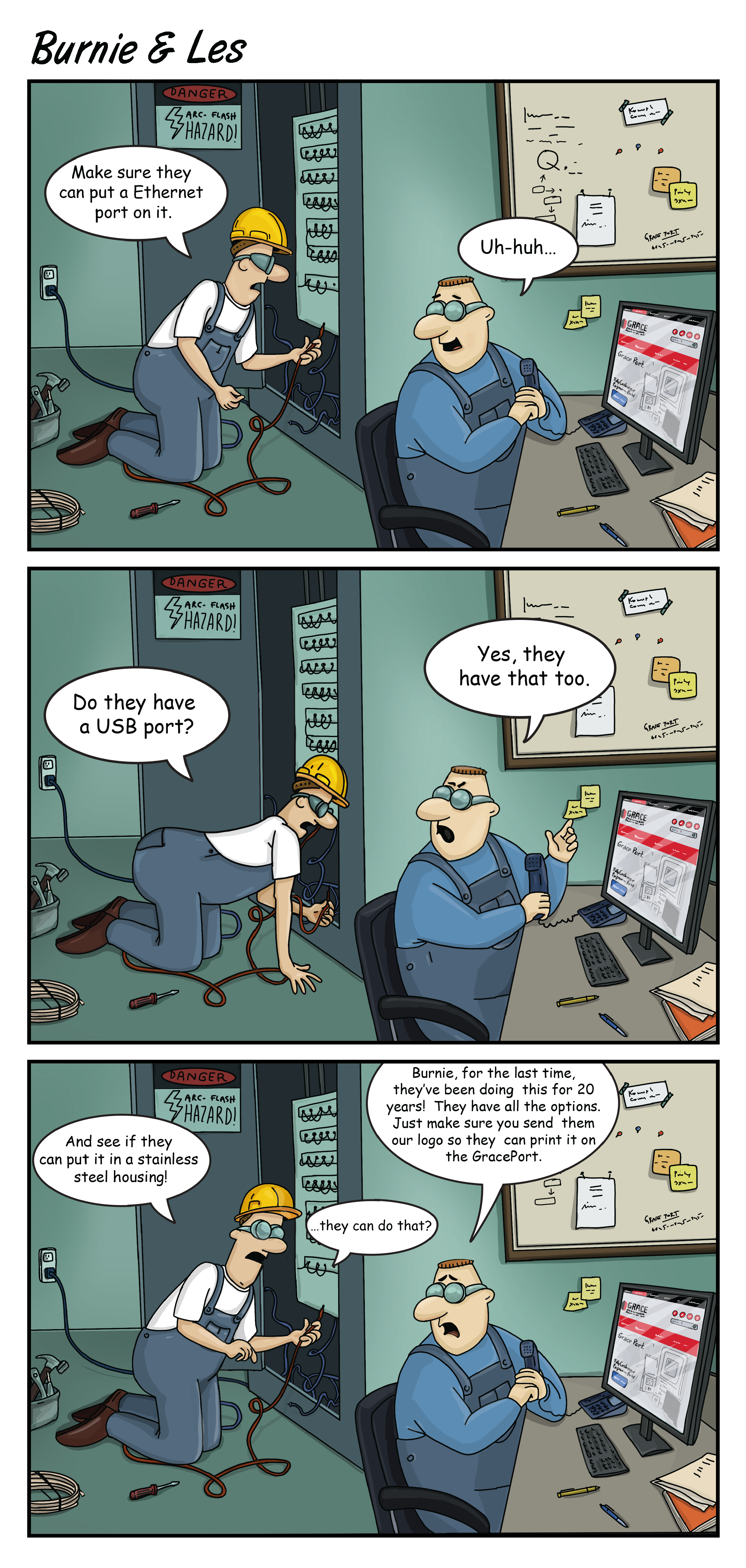

After reading our GracePort® eBook about how to make Industrial Control Panels (ICPs) safer, smarter, and more productive, Les learned that Grace's fully customizable GracePorts provide convenient access to ICPs safely through closed doors. These fully customizable communication ports make performing routine tasks on ICPs, such as programming PLCs, more efficient with thru-door safety technology.

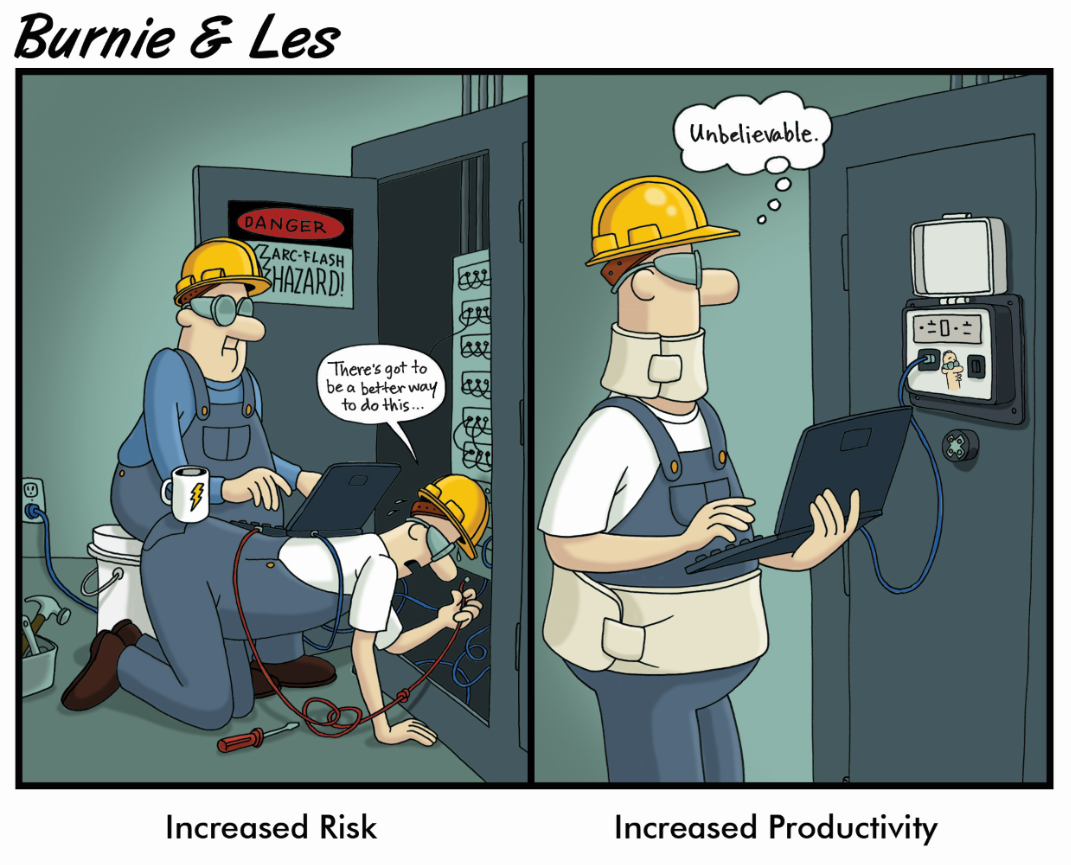

After many years of doing things the long, hard, and less safe way, Les finally ordered a GracePort panel interface connector. Burnie was shocked, to say the least, at what it had to offer all this time.

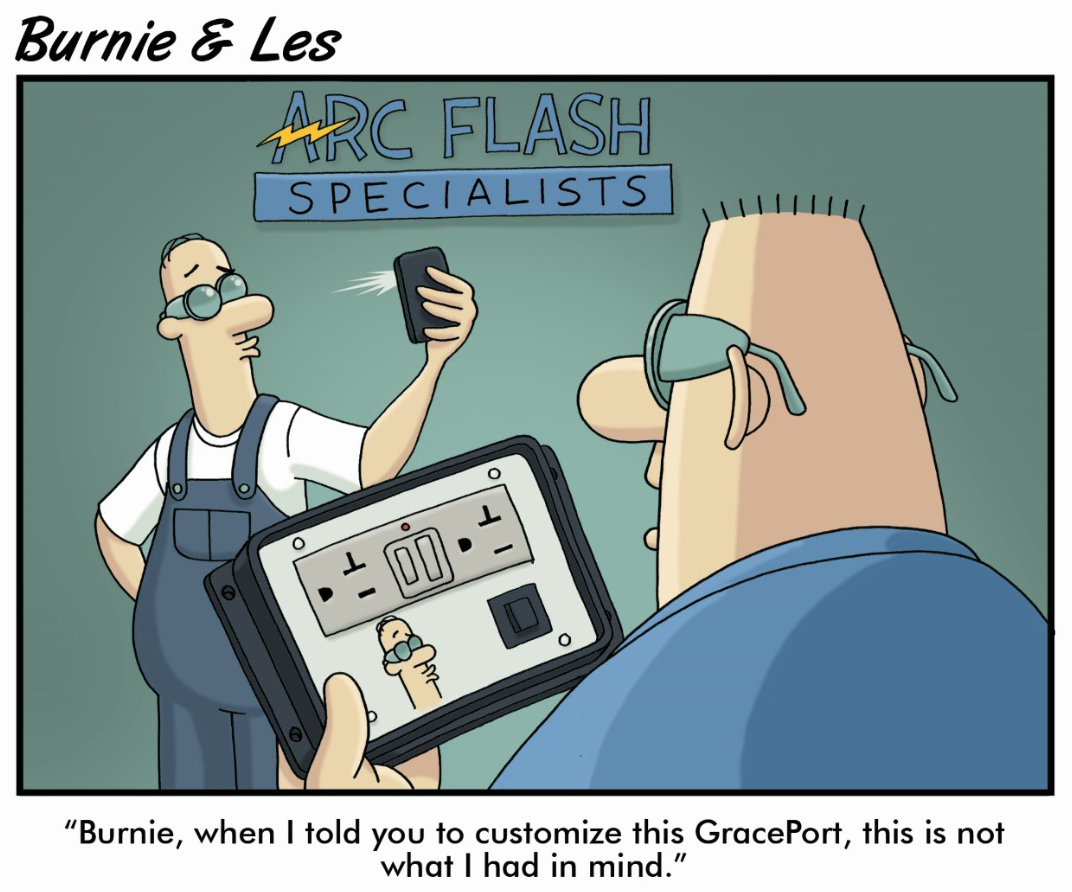

Burnie had one job. Each GracePort can not only be fully customized with components, power, and housing options; special text and company logos can also be added. With Burnie in charge of sending their company logo image, somehow he managed to mess even that up, or more likely his vanity got in the way. Add your company logo when you order a GracePort, but just don't leave a guy like Burnie in charge of sending us the image file!

Burnie had one job. Each GracePort can not only be fully customized with components, power, and housing options; special text and company logos can also be added. With Burnie in charge of sending their company logo image, somehow he managed to mess even that up, or more likely his vanity got in the way. Add your company logo when you order a GracePort, but just don't leave a guy like Burnie in charge of sending us the image file!

With their fancy new GracePort installed, imagine Burnie's surprise when he went to use the panel interface connector for the first time after years of doing it with the door open. Not only has their safety increased by keeping their panel closed, but the task itself has also become safer and quicker to perform using a GracePort. So easy, even a cartoon character can do it!

Top 10 Considerations for a Safer and More Productive ICP

- Understand that ICPs pose a significantly higher risk than your other electrical panels as it involves multiple voltages.

- Clearly evaluate worker qualifications and the task they are assigned to do.

- Perform risk analysis and implement control measures that are appropriate by evaluating the type of task, worker qualification, and equipment condition.

- Always try to implement elimination, substitution, and engineering controls in the order of hierarchy from the Risk Control Hierarchy chart as they are applied at the source of the hazard.

- Always use the equipment in accordance with manufacturers’ instructions for all the listed and labelled components.

- Ensure that your ICPs are provided with accurate equipment labels and description per UL 508A, NFPA 79, and NFPA 70 (NEC) standards.

- Ensure that your equipment is marked with appropriate warning labels with arc flash hazard information to include either Incident energy or PPE category.

- Provide GFCI receptacles that meet the enclosure type rating for all the accessory equipment for maintenance personnel.

- Keep electrical drawings up to date, avoid energized work permits and open-door work while the system is energized.

- Follow all your equipment and facility LOTO procedures.

BONUS TIP: Order a GracePort today!

Most facilities have robust safety programs, Lockout/Tagout (LOTO) procedures, and PPE in place to mitigate hazards while performing maintenance tasks around this equipment. However, having a safety policy and procedure built around equipment does not necessarily constitute an incident-free facility.

Learn how you can make your Industrial Control Panels (ICPs) safer and more productive with our FREE GracePort eBook! In this comprehensive ICP analysis, we look back at the problem our GracePort panel interface connector was initially created to solve. Starting with historical data of ICP safety incidents, we report how panel interface connectors improve ICP task productivity by 90% and mitigate safety risks.

Join us tomorrow for our next FREE webinar: 24x7 Vibration Monitoring of Rotational Assets Using IIoT Devices and Your PLC (0.1 CEUs) presented by Dr. Andy Zimmerman, CTO of Grace Technologies. Vibration Analysis is important to any industrial facility. While high-end technologies can provide 24x7 vibration monitoring of critical assets, these systems are often cost-prohibitive to deploy on non-critical equipment.

This session will address the affordable implementation of IIoT-based vibration monitoring, and its integration with PLCs. Register today: