At Grace, reliability and electrical safety is not just our business; it's our mission. When your mission is to minimize downtime, our GraceSense predictive maintenance solutions have the answer. Electrical maintenance prioritization is one of the major concerns that many facility owners and operators encounter. Electrical system breakdowns are a leading cause of equipment and business interruption losses. It’s a growing problem and the losses can be substantial.

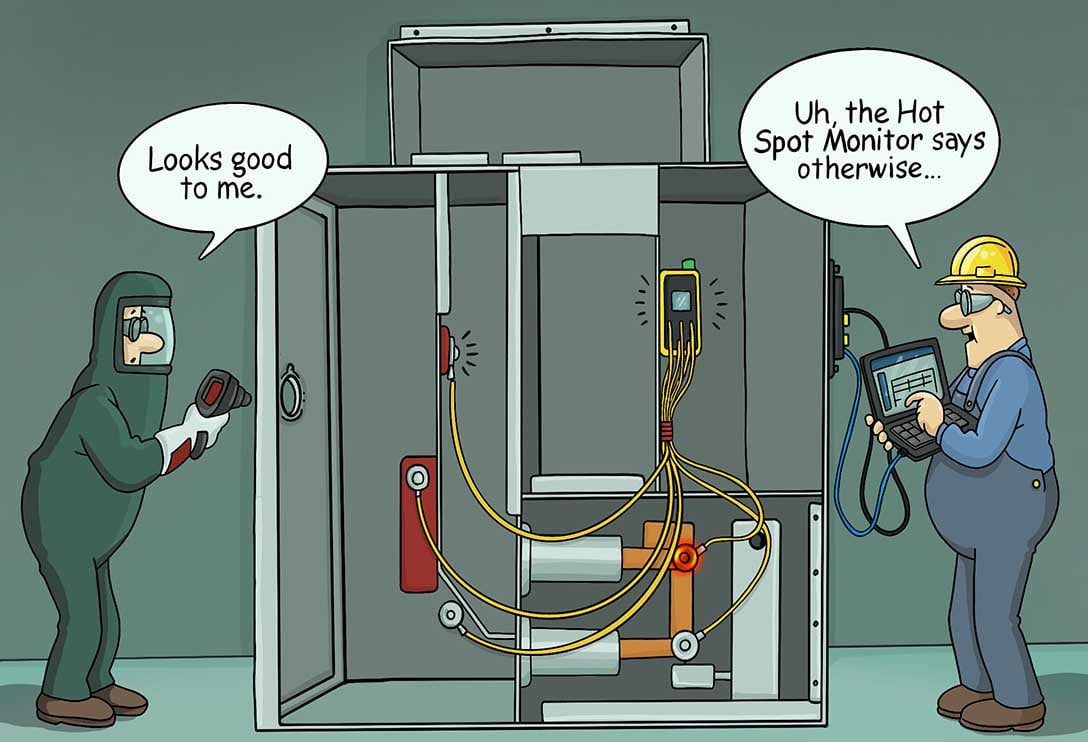

A common factor in determining the reliability and uptime of an electrical system is the condition and the availability of the power distribution equipment such as medium voltage and low voltage switchgear, transfer switches and MCCs used in the downstream. Since loose connections contribute to over 30% of all electrical failures and are a major cause for power outages, we've devised a solution to monitor those failure points and prevent unexpected downtime. By continuously and remotely monitoring your critical uptime assets, you can rest assured knowing you'll be alerted to problematic behavior before it becomes catastrophic by resulting in unplanned downtime.

The GraceSense Hot Spot Monitor is a non-conductive temperature monitoring and alarming device that identifies potential hot spots and enables users to predict failures in electrical equipment. Identifying faults before they occur saves money when unplanned outages, service interruptions, and equipment failures are avoided. The real win here is the ability to monitor the temperature data on a continuous basis while seamlessly integrating data into a plant-wide SCADA system. This technology also helps to monitor and trend temperature data on a real-time basis while the equipment is in fully loaded condition.

For more on how the Hot Spot Monitor is changing the game of Thermography and Electrical Maintenance programs, we have penned an eBook analyzing the features, benefits, and ROI. The content of this free eBook focuses on the concept of Predictive Maintenance and highlights the opportunities that GraceSense predictive solutions have to offer.

ICYMI: Last week, Technical Product Director, Bhanu Srilla, and IIoT Application Engineer, Bryce Brewer, analyzed the features and benefits of the GraceSense Hot Spot Monitor. There's a significant amount of information to unpack here and the two demonstrate precisely how the Hot Spot Monitor can enhance your electrical maintenance program with continuous, remote monitoring capabilities.

Temperature anomalies are one of the significant causes of electrical failures in many industrial and commercial equipment. While published data primarily points out unmaintained equipment as a leading cause of many failures, there is also significant evidence that suggests failures are a result of maintenance induced errors or work performed by unqualified persons. This live session addresses how to overcome these challenges and use various technologies to help prevent those failures.

The Factory Futurist Podcast

Don't miss the incredible connections and conversations being made on the Factory Futurist podcast with Drew Allen. Be sure to check out our latest episode. New episodes coming soon!

Subscribe to the Factory Futurist podcast:

Google Play

iTunes Podcasts

Stitcher

TuneIn

iHeartRadio

Stay safe and have a GREAT week!